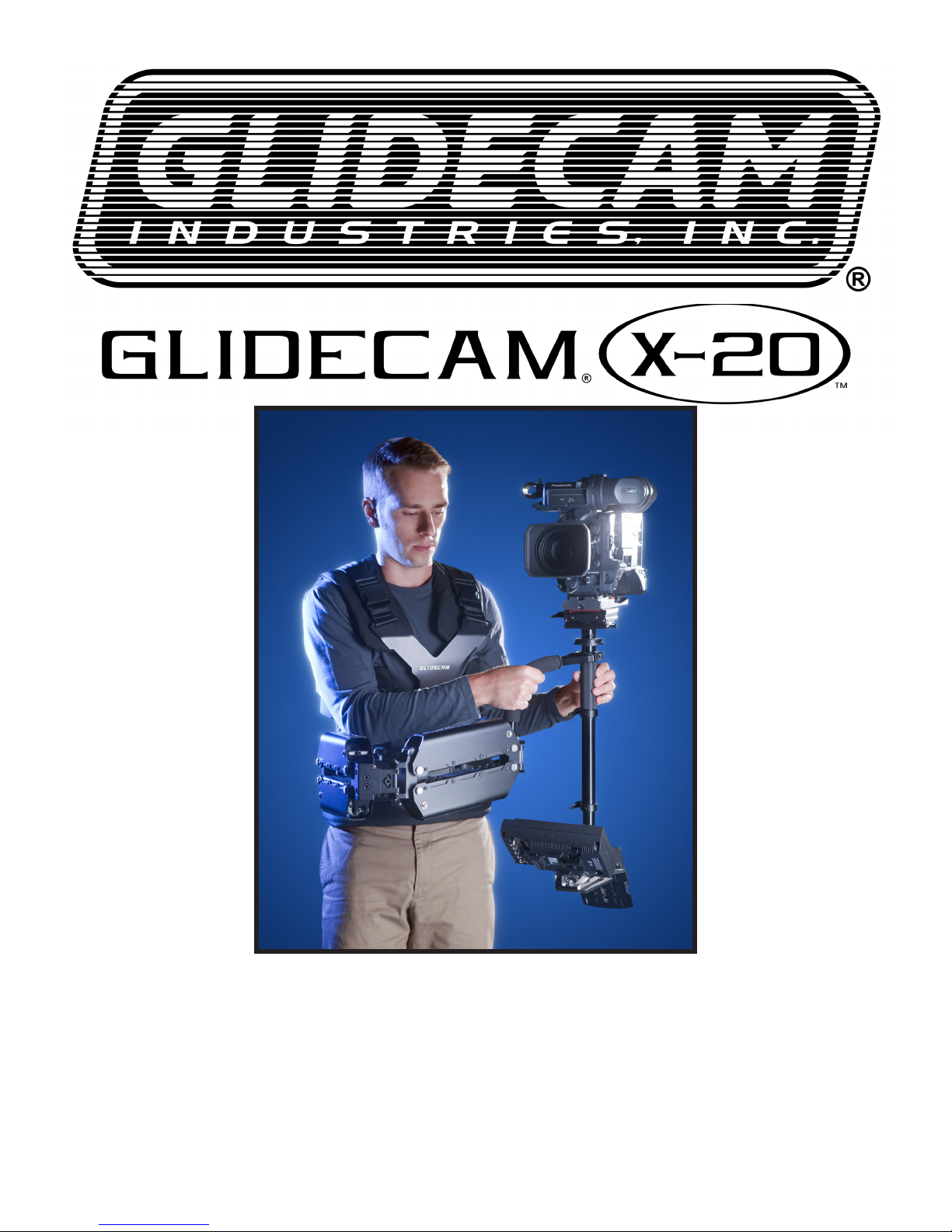

Congratulations on your purchase of a Glidecam X-20 System.

The Glidecam X-20 System is a lightweight, aluminum, hand-held camcorder

stabilizing system designed to allow you to walk, run, go up and down stairs and travel

over rugged terrain without any camera instability or shake. When used correctly

the Glidecam X-20 System can move with such uidity and grace as to be virtually

indistinguishable from shots made by professional dollies, cranes and stabilizers.

The Glidecam X-20 System is the most versatile and dynamic of all the consumer

camcorder stabilizers on the market. It can shoot straight up and down, or even

sideways and still produce stable images.

Fluid tilts and pans, crane-like booms, dolly-type maneuvers, and the ability to shoot

smooth shots from moving vehicles are all easily accomplished with the Glidecam

X-20 System. The offset gimbaled handle-grip and enclosed bearing assembly allows

your hand to move freely in several directions, while the horizontal yoke allows your

hand and arm to move up and down, alleviating the bouncing, pogo-type action often

associated with our competitors’ systems. The upper camera platform moves back

and forth, and side to side to quickly allow the balancing of your camera in relationship

to the counterweights. By varying the length of the central post, the Glidecam X-20

System can support any camcorder weighing from 10-20 pounds.

While the Glidecam X-20 System is in essence a very simple device, its simplicity

doesn’t lend ease in answering that often asked question, “how does it work?” To

answer this question completely would require delving into Newtonian Physics. We

would have to explain - center of gravity displacement, inertia, friction and angular

motion reduction etc. However, a quick answer reveals the Glidecam X-20 System

works by isolating your hand and arm’s motions from your camera, while your camera

is balanced in a relatively motionless state.

The Glidecam X-20 System requires practice and understanding to achieve

professional looking results. We highly recommend that the user read this manual

thoroughly before setting up and operating the Glidecam X-20 System. Doing so

will save you time, and will minimize the risk of damage to your camcorder or the

Glidecam X-20 System. It is important to perform and follow the Set-up and Operation’s

procedures in the proper sequence to avoid both frustration and a possible accident.

If you have any need for technical assistance, you can call our Technical Support

Line at 1-781-585-7900, Monday through Friday between the hours of 9:00 am and

5:00 pm, Eastern Time.

We’re sure you will nd many years of enjoyment with your Glidecam X-20 System

once you have it up and running.

#1 INTRODUCTION

3