3/2003

GENERAL INDEX

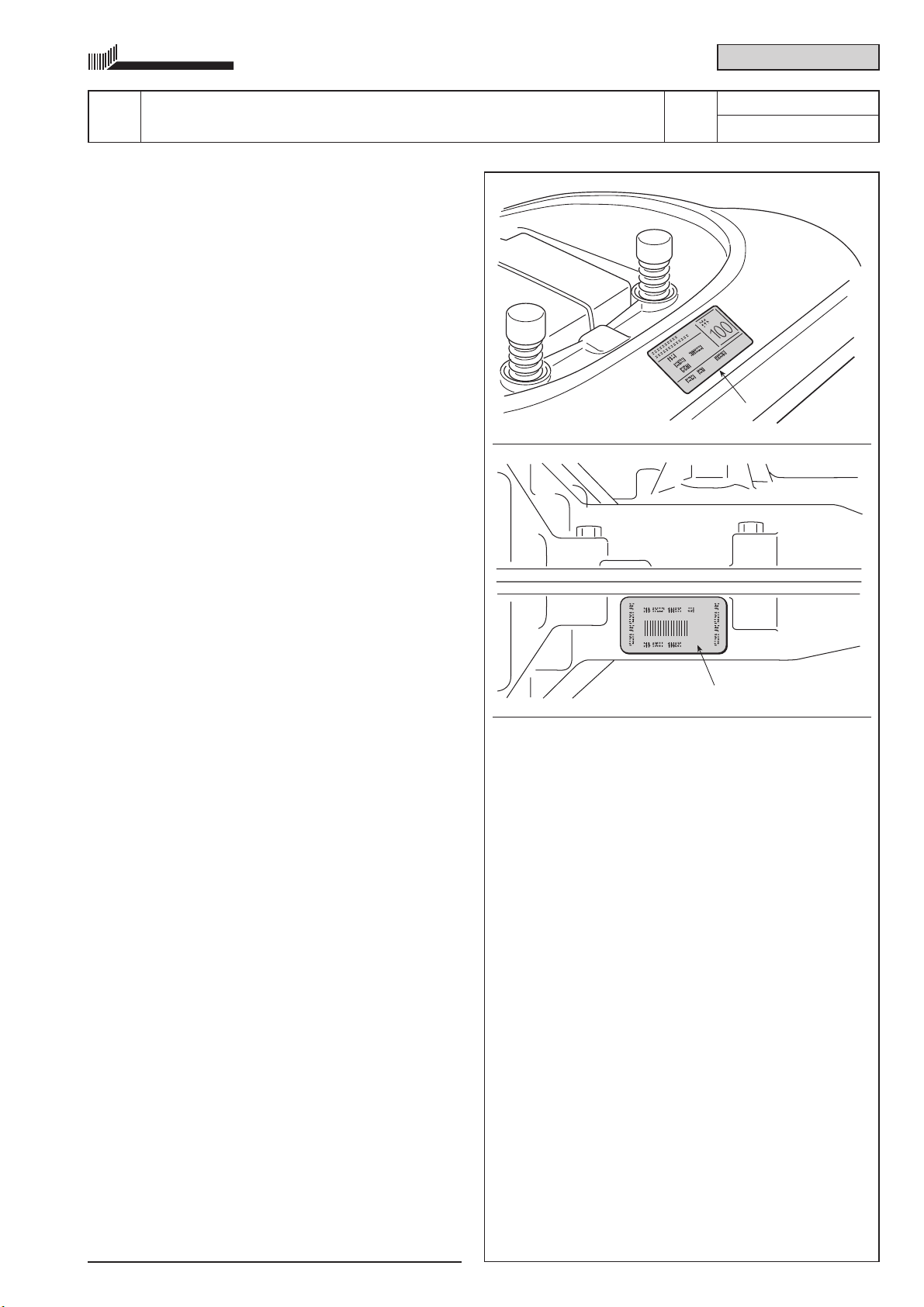

1.1 0 Identification

1.2 0 Guarantee validity

1.3 0 Service repairs after guarantee period

1.4 0 Fault notification

1.5 0 Spare parts request

1.6 0 Safety regulations

2.1 0 Level of staff training

2.2 0 Precautions while working

2.3 0 Tools

2.4 0 Slings

2.5 0 Lifting

2.6 0 Vertical positioning

2.7 0 Practical hints

3.1 1 Criteria for maintenance

3.2 0 Occasional tuning

3.3 0 Routine maintenance

4.1 0 Blades engagement adjustment

4.2 0 Blades brake adjustment

4.3 0 Brake adjustment

4.4 0 Drive belt adjustment

4.5 0 Drive pedal adjustment ( ➤hydrostatic drive models)

4.6 0 Aligning the cutting deck

4.7 0 Steering allowance adjustment

4.8 0 Steering geometry adjustment

4.9 0 Checking blades alignment

4.10 1 Sharpening and balancing of the blades

5.1 0 Removal of front hood

5.2 0 Removal of wheel cover

5.3 0 Removal of the collector channel

5.4 0 Removal of the dashboard

5.5 0 Removal of the engine

5.6 0 Removal of the rear axle

5.7 0 Removal of the cutting deck

6.1 0 Replacement of tyres and wheels

6.2 0 Replacement of front wheel bearings

6.3 0 Dismantling the steering pinion and ring gear

6.4 0 Replacement of the drive belt

6.5 0 Replacement of the small wheels for the drive belt

6.6 0 Replacement of the blades control belt

6.7 0 Replacement of the blades connection belt

6.8 0 Replacement of the blades engagement cable

6.9 0 Replacement of the supports and shafts of the blades

6.10 0 Replacement of the accelerator

6.11 0 Replacement of the brake pads and disc

7.1 0 Guide to the identification of problems in the electrical system

7.2 0 Summary table for the cutting in of the safety devices

7.3 0 Safety microswitches and switches operation check

7.4 0 Terminal board supply check

7.5 0 Carburettor solenoid valve operation check

7.6 0 Starter relay operation check

7.7 0 Electromagnetic clutch operation check ( ➤in models with electromagnetic engagement)

7.8 0 Electronic card operation check

7.9 0 Recharge circuit check

7.10 0 Care and maintenance of the sealed battery

7.11 0-1 Fitting safety microswitches

7.12 0-1 Electrical diagrams

8.1 1 Summary of tightening torques

8.3 0 Summary of main assembly sizes and checking values

8.3 0 Special tools

102 - 122

i.1- INDEX

2 / 2

from 2000 to ••••

WORKSHOP MANUAL

page