2

TABLE OF CONTENTS

SAFETY WARNING

This R/C airplane is not a toy! If misused, it can cause serious bodily injury and/or damage to property. Fly only in open

areas and preferably at a dedicated R/C flying site. We suggest having a qualified instructor carefully inspect your

airplane before its first flight. Please carefully read and follow all instructions included with this airplane, your radio

control system and any other components purchased separately.

Safety Warning ...............................................................2

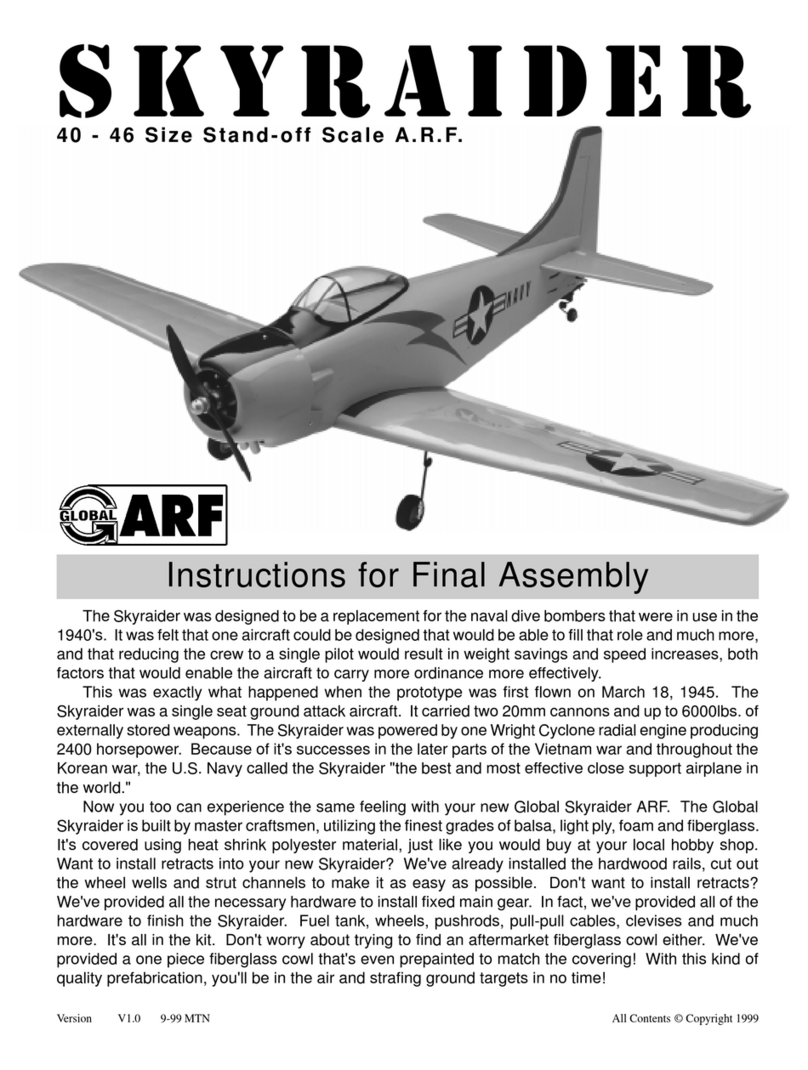

Introduction ....................................................................3

Our Recommendations...................................................4

Additional Items Required .............................................5

Tools and Supplies Required .........................................5

Metric Conversion Chart................................................5

Kit Contents....................................................................6

Replacement Parts ..........................................................7

A Note About Covering .................................................8

Wing Assembly ..............................................................8

Installing the Dihedral Brace...................................8

Joining the Wing Halves..........................................9

Wing Mounting ..............................................................9

Installing the Wing Bolt Doubler ............................9

Mounting the Wing ................................................10

Belly Pan ......................................................................10

Aligning the Belly Pan...........................................10

Installing the Belly Pan..........................................11

Horizontal Stabilizer .................................................... 11

Aligning the Horizontal Stabilizer ........................11

Mounting the Horizontal Stabilizer .......................12

Vertical Stabilizer .........................................................13

Aligning the Vertical Stabilizer .............................13

Mounting the Vertical Stabilizer...........................13

Control Surface Hinging ..............................................14

Hinging the Ailerons..............................................14

Hinging the Elevator Halves .................................14

Hinging the Rudder................................................15

Tail Wheel ....................................................................15

Assembling the Bracket .........................................16

Installing the Tail Wheel Bracket ..........................16

Installing the Tail Wheel........................................17

Main Landing Gear ......................................................17

Installing the Aluminum Strut ...............................17

Installing the Wheels and Wheel Pants .................18

Aligning the Wheel Pants ......................................19

Engine Installation .......................................................19

Installing the Engine Mount Beams ......................19

Aligning the Engine ...............................................19

Servo Installation .........................................................20

Installing the Servos ..............................................20

Throttle Control System...............................................21

Installing the Pushrod Tube ...................................21

Installing the Pushrod ............................................22

Installing the Servo Connector ..............................22

Adjusting the Throttle Pushrod .............................23

Elevator Control System ..............................................23

Installing the Control Horns ..................................23

Installing the Pushrod ............................................24

Adjusting the Pushrod ...........................................25

Rudder Control System ................................................25

Installing the Control Rod .....................................25

Installing the Pull-Pull Cables ...............................26

Adjusting the Pull-Pull Cables ..............................27

Aileron Control System ...............................................28

Installing the Control Horns ..................................28

Installing the Pushrods...........................................28

Adjusting the Pushrods ..........................................29

Fuel Tank ......................................................................30

Assembling the Stopper.........................................30

Installing the Stopper Assembly............................30

Installing the Fuel Tank .........................................31

Cowling ........................................................................31

Aligning the Cowling ............................................31

Installing the Cowling............................................33

Installing the Propeller and the Spinner ................33

Canopy .........................................................................33

Aligning the Canopy..............................................33

Installing the Canopy .............................................34

Final Assembly.............................................................34

Applying the Decals ..............................................34

Installing the Wing Skids.......................................34

Installing the Switch ..............................................35

Installing the Receiver and the Battery .................35

Balancing......................................................................35

Balancing the Freestyle ARF.................................35

Lateral Balancing .........................................................36

Control Throws ............................................................36

Preflight Check.............................................................36

Safety Guidelines .........................................................37

Flying the Freestyle ARF.............................................37

3D Aerobatic Flying Setup ..........................................38

Radio Setup for 3D Flying...........................................39

Trim Chart ....................................................................40

Product Evaluation Sheet.............................................43