2

TABLE OF CONTENTS

Elevator Pushrod ..................................................20

Installing the Control Horn ............................20

Installing the Pushrod Wire ...........................20

Adjusting the Elevator Pushrod .....................21

Rudder Pushrod ....................................................22

Installing the Control Horn ............................22

Installing the Pushrod Wire ...........................22

Adjusting the Rudder Pushrod.......................23

Aileron Pushrods ..................................................24

Installing the Aileron Pushrods .....................24

Adjusting the Aileron Pushrods.....................25

Final Assembly.....................................................25

Installing the Fuel Lines ................................25

Installing the Spinner .....................................25

Installing the Switch ......................................26

Installing the Battery and Receiver................26

Applying the Decals.......................................27

Balancing ..............................................................27

Control Throws.....................................................28

Preflight Check.....................................................28

Safety ....................................................................28

Notes.....................................................................29

ABC's of Flying....................................................29

Basics of Flight.....................................................30

Glossary of Terms.................................................32

Product Evaluation Sheet .....................................35

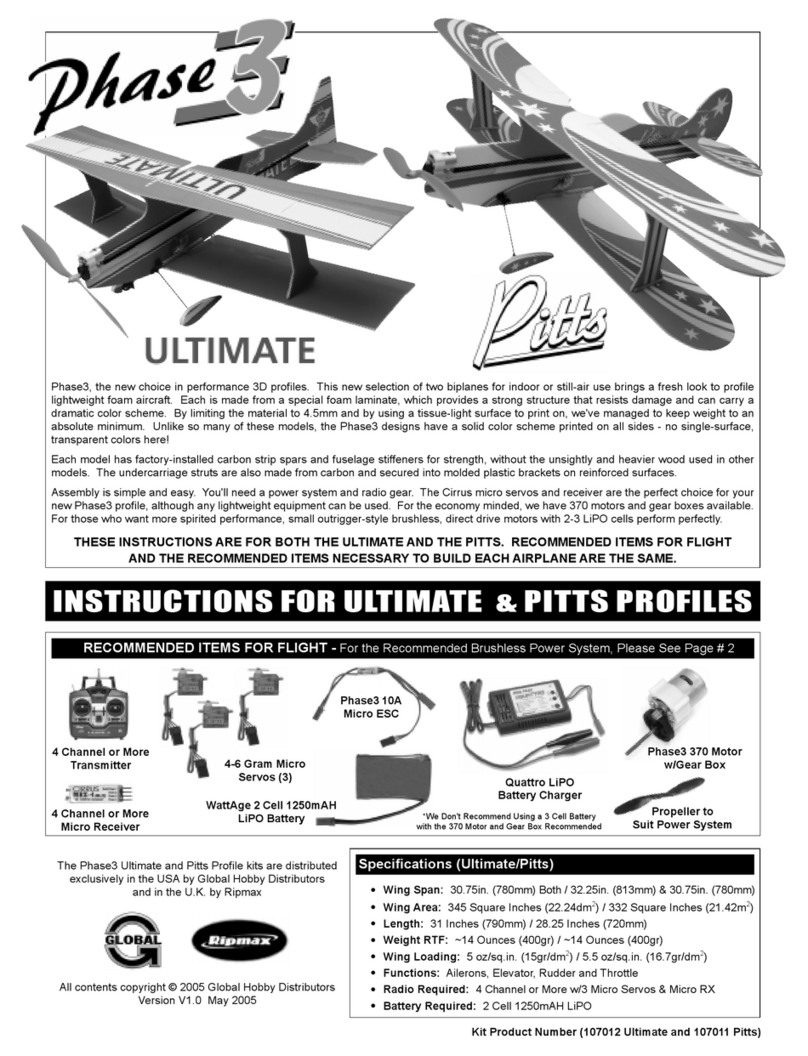

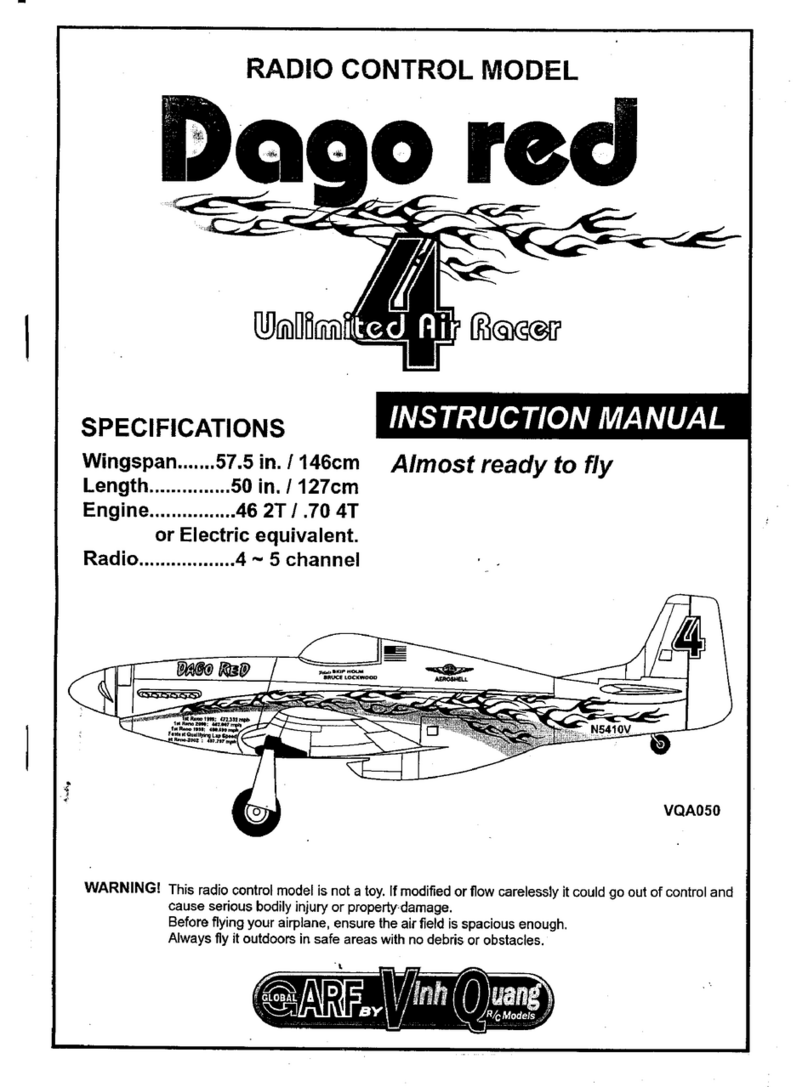

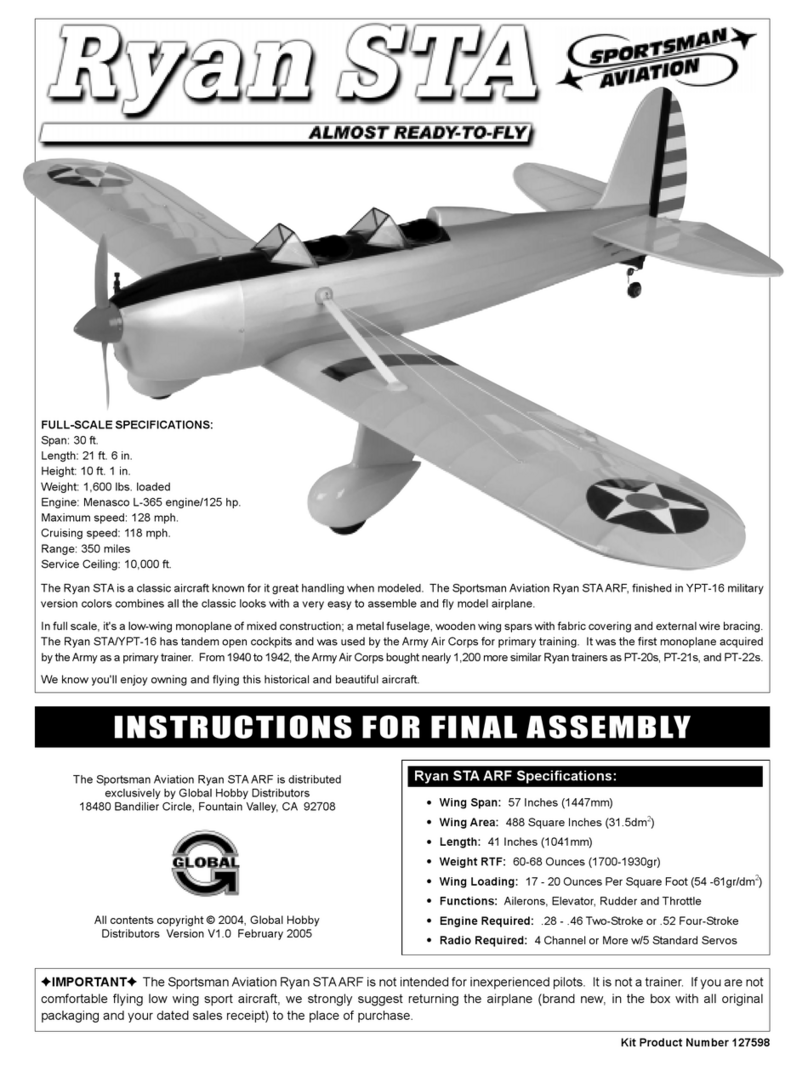

Introduction ............................................................3

Our Recommendations ...........................................4

Kit Contents............................................................7

Metric Conversion Chart ........................................8

Full Size Hardware Drawings ................................9

Additional Items Required ...................................10

Safety Warning .....................................................10

A Note About Covering .......................................11

Wing Assembly ....................................................11

Joining the Wing Halves ................................11

Wing Installation ..................................................12

Installing the Wing Bolts ...............................12

Horizontal Stabilizer.............................................12

Mounting the Horizontal Stabilizer ...............12

Vertical Stabilizer .................................................13

Mounting the Vertical Stabilizer....................13

Main Gear Installation..........................................13

Installing the Main Gear Wires......................13

Installing the Main Gear Wheels ...................14

Nose Gear Installation ..........................................14

Installing the Nose Gear Strut........................14

Installing the Nose Gear Wheel .....................15

Fuel Tank ..............................................................15

Installing the Stopper Assembly ....................15

Installing the Fuel Tank .................................16

Engine Installation................................................17

Mounting the Engine .....................................17

Installing the Throttle Pushrod ......................17

Servo Installation..................................................17

Installing the Fuselage Servos .......................17

Installing the Aileron Servo Tray ..................18

Installing the Aileron Servo...........................18

Throttle Pushrod ...................................................19

Installing the Servo Connector ......................19

Adjusting the Throttle Linkage......................20