OPERATION OF HIGH SPEED FLOOR MACHINE

4

READ OPERATORS MANUAL

THOROUGHLY PRIOR TO

OPERATING OR SERVICING

THIS MACHINE

GENERAL USE

1. Remove any obstructions or other obstacles in the area

which is to be cleaned.

2. Remove dust recovery bag and empty it out in a trash

receptacle. Replace dust recovery bag on machine,

ensuring it is sealed tightly to the machine.

3. Place the handle in the upright position and tilt machine

back until handle rests on the floor.

4. Remove the pad center gripping device by unscrewing

the thumbscrews.

5. Place an approved burnishing pad on the pad driver

and re-attach the center gripping device. (check with

Global Equipment (1-800-645-1232) for approved

pads).

6. Place machine back into its upright position.

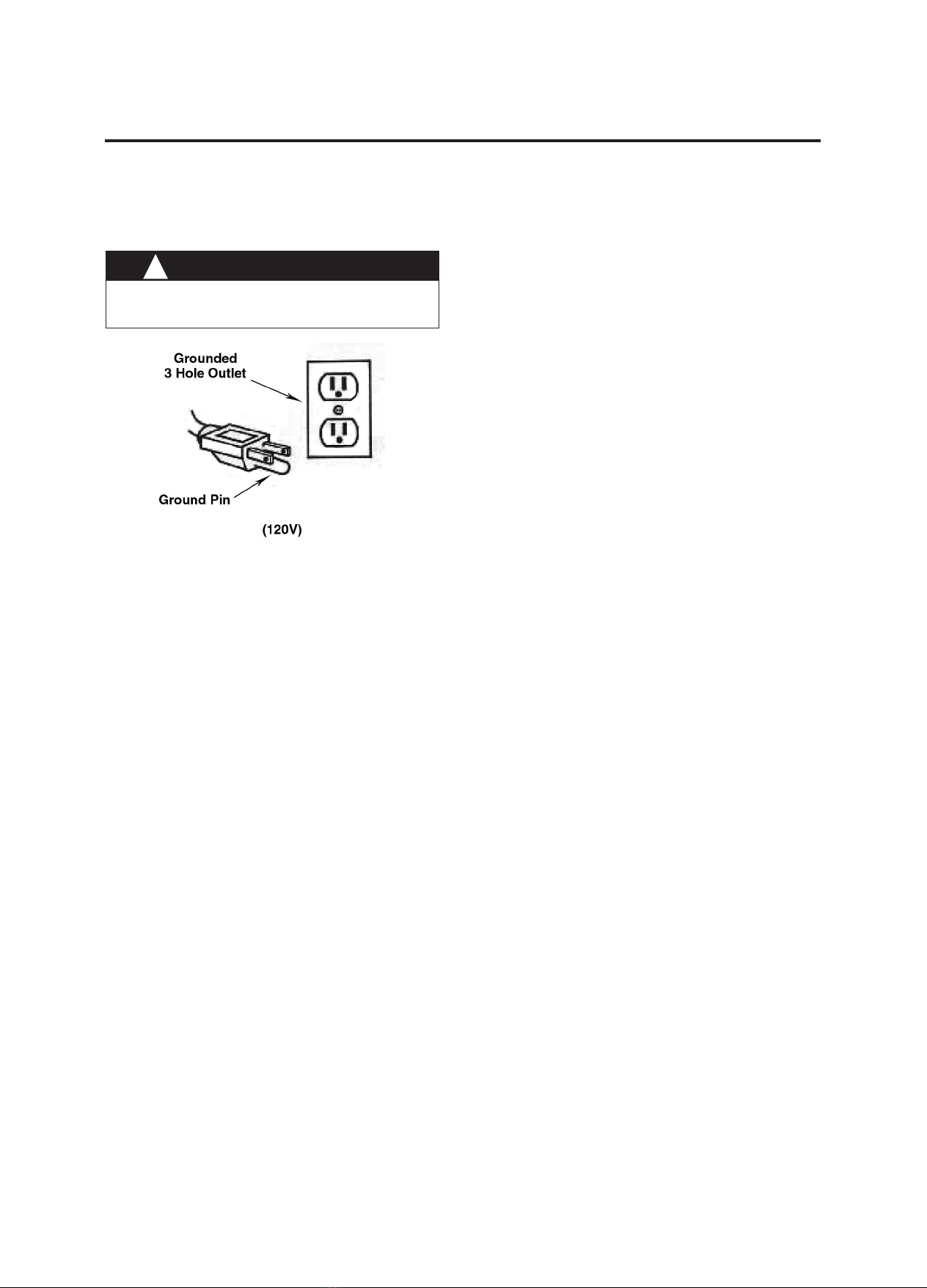

7. Plug power cord into grounded outlet.

8. The handle height may be adjusted by lifting up on the

handle release lever, located on the right side of the

switch housing. Pull trigger and lower handle to desired

operating position. Release trigger to lock handle into

place.

9. To start the machine, push on the red safety release

button located on the top of the switch housing and

squeeze either switch lever.

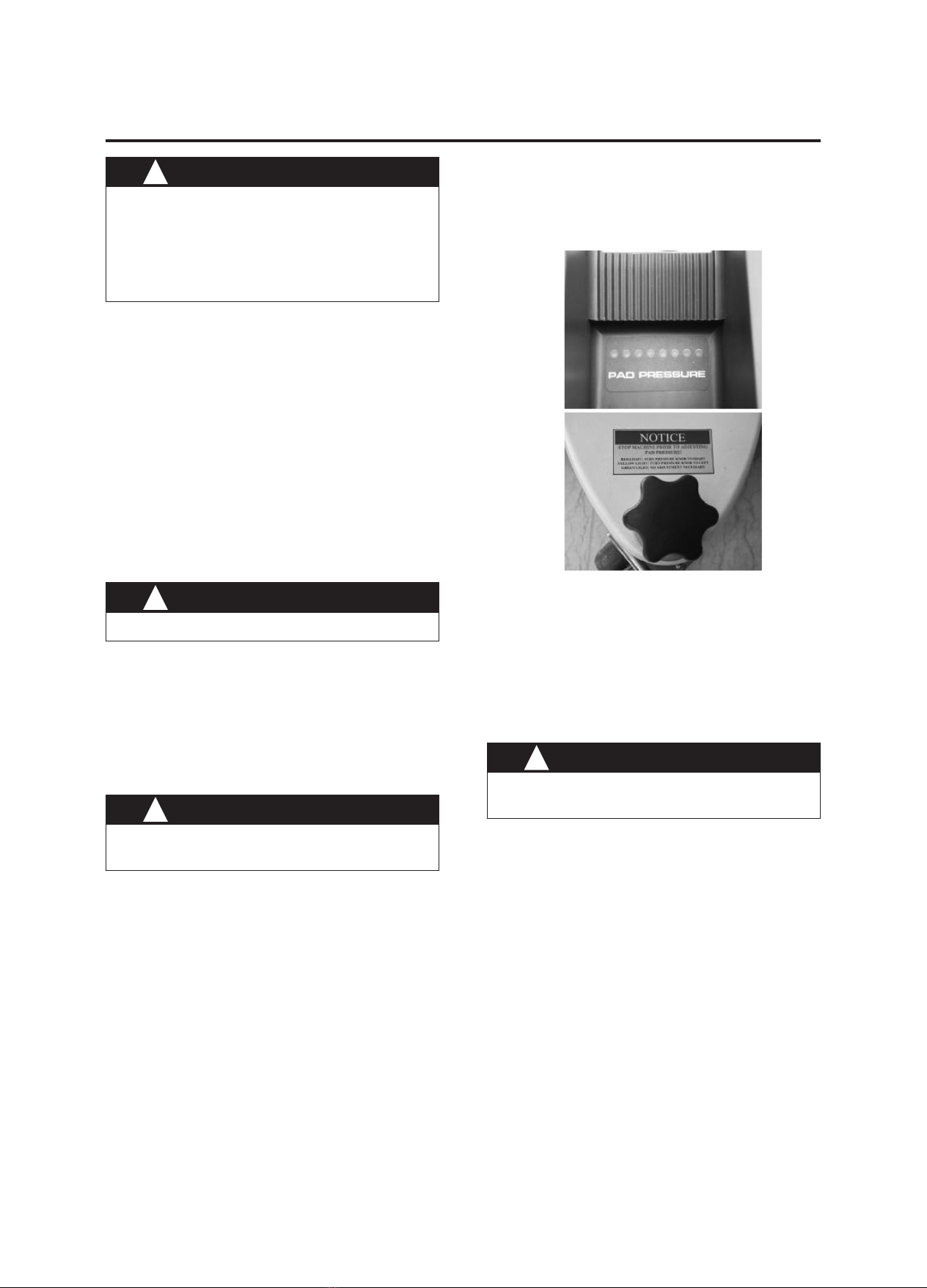

10. Once the machine has reached operating speed, look

at the digital pad pressure meter located on the top of

the motor cover. There are 3 light colors which will help

you determine optimal pad pressure for operating the

machine. RED LIGHT(S): If one or both red lights are

illuminated, stop the machine and turn the pad

pressure adjustment knob to the right to reduce pad

pressure. YELLOW LIGHT(S): If one or both yellow

lights is illuminated, stop the machine and turn the pad

pressure adjustment knob to the left to increase the

amount of pad pressure. GREEN LIGHT(S): If one, two

or three green lights are illuminated, the machine is

running at the optimal pad pressure and you may begin

working.

11. When the machine is in operation, both hands should

be gripping on the handle.

12. To stop the machine at any time, simply release the

switch lever, and the machine will stop automatically.

MAINTENANCE

To keep the machine performing well for many years,

please follow the following maintenance procedures.

1. Unplug machine as soon as you are done using it.

2. Remove dust recovery bag and empty contents into a

trash receptacle. Inspect dust recovery bag for any

damage prior to replacing it on the machine.

3. Clean the outside of the machine with a mild cleaner.

4. Check power cord for any damage. If damage is

detected, replace power cord immediately.

5. Lubricate wheels with a water resistant lubricant once a

month.

6. Check machine for loose or missing nuts and bolts, and

replace as necessary.

7. If the machine is used in a dusty environment, you may

remove the motor cover and blow the motor clean with

compressed air. This will ensure proper ventilation, and

allow the motor to run cooler.

STORAGE

1. Unplug machine from power source and wrap cord on

handle.

2. Store machine in upright position and in a dry area.

WARNING

Be sure the machine is not plugged into an outlet.

!

WARNING

Never use an extension cord in

conjunction with the standard power cord.

!

WARNING

Always confirm that the machine is unplugged

prior to performing any maintenance or repairs.

!

CAUTION

THIS IS A SPECIALIZED MACHINE

WHICH REQUIRES THE OPERATOR TO

UTILIZE AN APPROVED PAD, AND

MUST BE ADJUSTED PROPERLY TO

ENSURE THE HIGHEST POSSIBLE

PERFORMANCE AND PRODUCTIVITY.

!