GLOBALJIG INTERNATIONAL S.r.l.

3

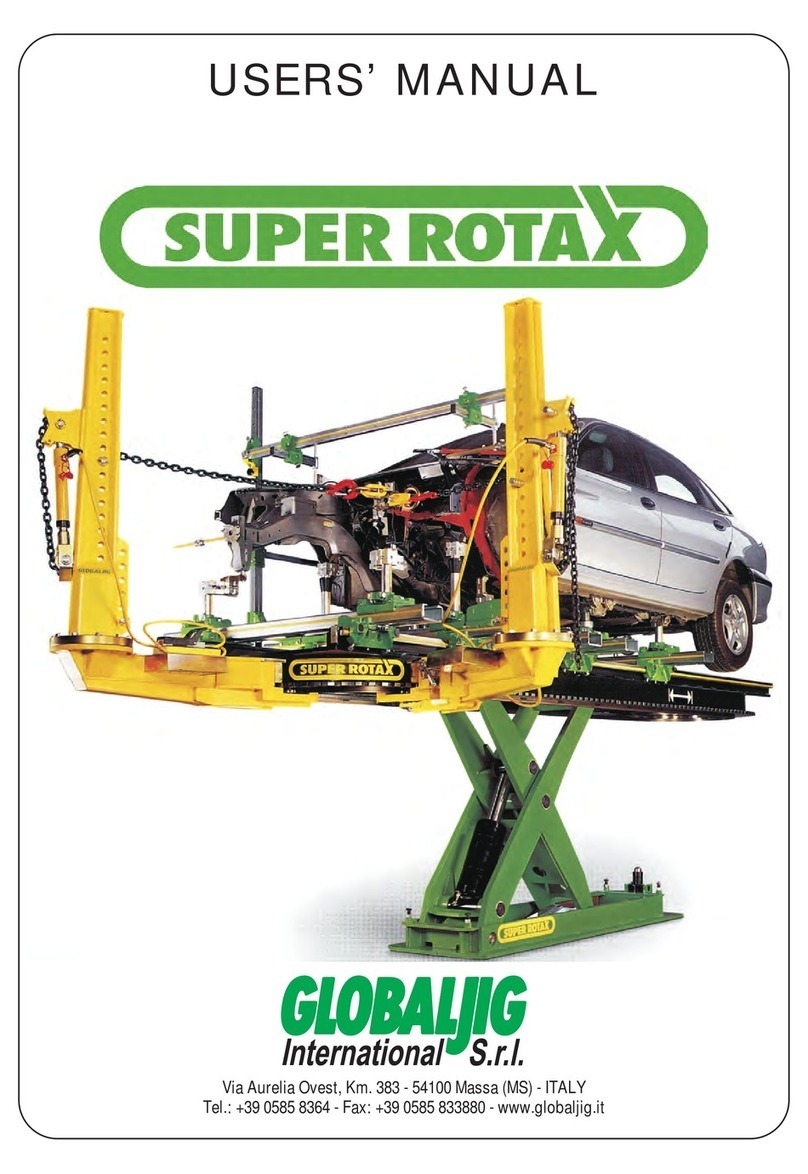

Index

1. USE AND STORAGE OF THE

INSTALLATION, USE AND MAINTENANCE MANUAL...........................................................................4

1.1. Purposes and intended users of the Installation, Use and Maintenance manual .................................................................4

1.2. Definitions and terminology...................................................................................................................................................4

1.3. Structure of the manual.........................................................................................................................................................5

1.4. Storing the manual................................................................................................................................................................6

1.5. Updating................................................................................................................................................................................6

2. GENERAL DESCRIPTION........................................................................................................................7

2.1. Encumbrance dimensions of the lifting platform...................................................................................................................7

2.2. User.......................................................................................................................................................................................7

2.3. Consignment.........................................................................................................................................................................7

2.4. Identification of the various versions.....................................................................................................................................8

2.5. Potential and limitations for the lifting platform......................................................................................................................8

2.6. Lifting platform orientation.....................................................................................................................................................9

2.7. Operating modes.................................................................................................................................................................10

2.8. Safety devices.....................................................................................................................................................................10

2.9. Operating indications and instructions................................................................................................................................10

3. TECHNICAL DESCRIPTION OF THE LIFTING PLATFORM.................................................................11

3.1. General information.............................................................................................................................................................11

3.2. Identification of the parts.....................................................................................................................................................11

3.3. Technical description..........................................................................................................................................................12

4. INSTALLATION OF THE LIFTING PLATFORM.....................................................................................14

4.1. Transport and handling.......................................................................................................................................................14

4.2. Storage ...............................................................................................................................................................................14

4.3. Application of the towing arm..............................................................................................................................................16

4.4. Towing arm operating positions..........................................................................................................................................17

4.5. Lifting platform installation and work area...........................................................................................................................18

4.6. Foreseen environmental operating conditions....................................................................................................................19

4.7. Installation characteristics...................................................................................................................................................19

4.8. System connections............................................................................................................................................................20

4.9. Commissioning the Koala lifting platform............................................................................................................................20

5. INSTRUCTIONS FOR USE.....................................................................................................................21

5.1. Introductory notes...............................................................................................................................................................21

5.2. Command and control devices............................................................................................................................................21

5.3. Operating procedures.........................................................................................................................................................22

5.4. Adjustments........................................................................................................................................................................23

6. SAFETY RELATED DEVICES................................................................................................................24

6.1. Introduction.........................................................................................................................................................................24

6.2. Protection devices...............................................................................................................................................................24

6.3. Residual risks......................................................................................................................................................................24

7. MAINTENANCE INTERVENTIONS.........................................................................................................25

7.1. Introductory notes...............................................................................................................................................................25

7.2. Customer assistance service..............................................................................................................................................25

7.3. Routine maintenance..........................................................................................................................................................25

7.3.1 Cleaning the lifting platform.......................................................................................................................................25

7.3.2 Checking the efficiency of the safety catch................................................................................................................26

7.4. Breakdowns or malfunctions...............................................................................................................................................26

7.5. Special Maintenance...........................................................................................................................................................26

8. SPARE PARTS INFORMATION.............................................................................................................27

8.1. General information.............................................................................................................................................................27

8.2. Components recommended to keep in stock......................................................................................................................27

9. INSTRUCTIONS FOR DISMANTLING AND DISPOSING OF THE LIFTING PLATFORM.....................28

9.1. Removing the connections of the lifting platform................................................................................................................28

9.2. Preparing the lifting platform for handling and transport.....................................................................................................28

9.3. Disposal of the lifting platform.............................................................................................................................................28

10. ANNEXES................................................................................................................................................29

10.1. List of Annexes ...................................................................................................................................................................29

11. MACHINE LOG BOOK............................................................................................................................53