General Information 5

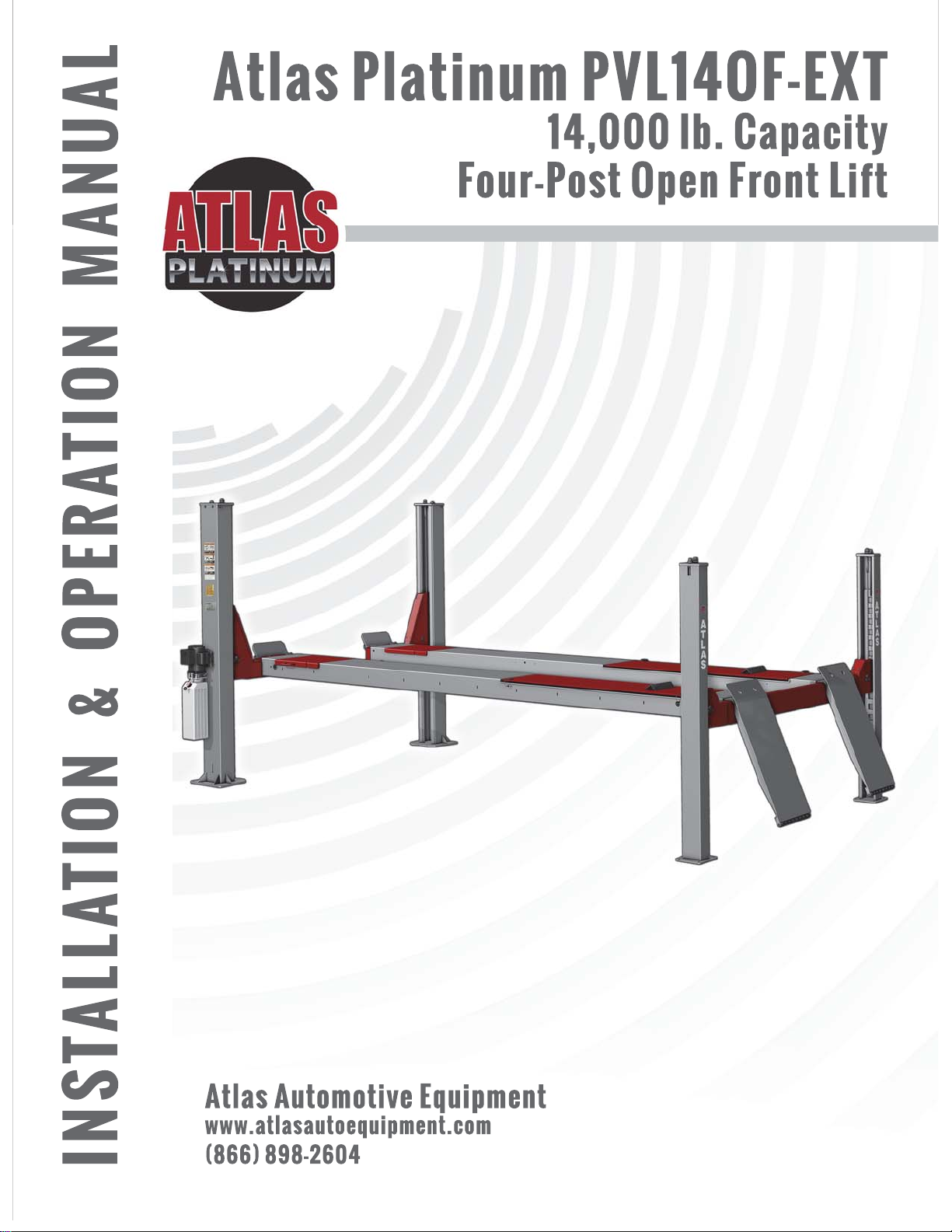

PVL14OF-EXT

General Information

This chapter contains warning instructions to operate the lift properly and

prevent injury to operators or objects. This manual has been written to be used

by shop technicians in charge of the lift (operator) and routine maintenance

technician (maintenance operator).

The operating instructions are considered to be an integral part of the machine

and must remain with it for its whole useful life. Read every section of this

manual carefully before operating the lift and unpacking it since it gives helpful

information about:

• safety of people

• safety of the lift

• safety of lifted vehicles

The company is not liable for possible problems, damage, accidents, etc.

resulting from failure to follow the instructions contained in this manual.

Only skilled technicians of AUTHORISED DEALERS or SERVICE CENTERS

AUTHORIZED by the manufacturer shall be allowed to carry out lifting, transport,

assembling, installation, adjustment, calibration, settings, extraordinary

maintenance, repairs, overhauling and dismantling of the lift.

The manufacturer is not responsible for possible damage to people,

vehicles or objects if said operations are carried out by unauthorized

personnel or the lift is improperly used.

Any use of the machine made by operators who are not familiar with the

instructions and procedures contained herein shall be forbidden.

1.1 Manual Keeping

For a proper use of this manual, the following is recommended:

• Keep the manual near the lift, in an easily accessible place.

• Keep the manual in an area protected from the damp.

• Use this manual properly without damaging it.

• Any use of the machine made by operators who are not familiar with the

instructions and procedures contained herein shall be forbidden.