BAER Your Complete Performance Brake Supplier!

Baer, Incorporated 3108 W. Thomas Road, Suite 1201 Phoenix, Arizona 85017

Page 1 of 4

Installation Instructions

Product: Rear GT disc conversion Instruction Part Number: 6000269

Vehicle

Make: GM Pickup

Model: GMT900 C or K10

Year(s): 2005>

Notices – Read and Follow BEFORE ATTEMPTING INSTALLATION

• All installations require proper safety procedures and protective eyewear.

• All installations assume basic mechanical skill and a factory service manual for the vehicle on

which the installation is to be performed.

• All references to LEFT side of vehicle always refer to the Driver’s side of the vehicle.

• Any installation requiring you to remove a wheel or gain access under the vehicle requires use of

jack stands appropriate to the weight of the vehicle. In all cases Baer recommends jack stands

rated for at least 2-tons.

• A selection of hand tools sufficient to engage in the installation of these products is assumed and

is the responsibility of the installer to have in his/her possession prior to beginning this

installation. All installations, which require removal of hydraulic hoses and/or bleeding of the

brakes, require appropriate fitting/line wrenches, as well as a safety catch can and protective

eyewear. Other than these items, if unique or special tools are required they are listed in the

section for that step.

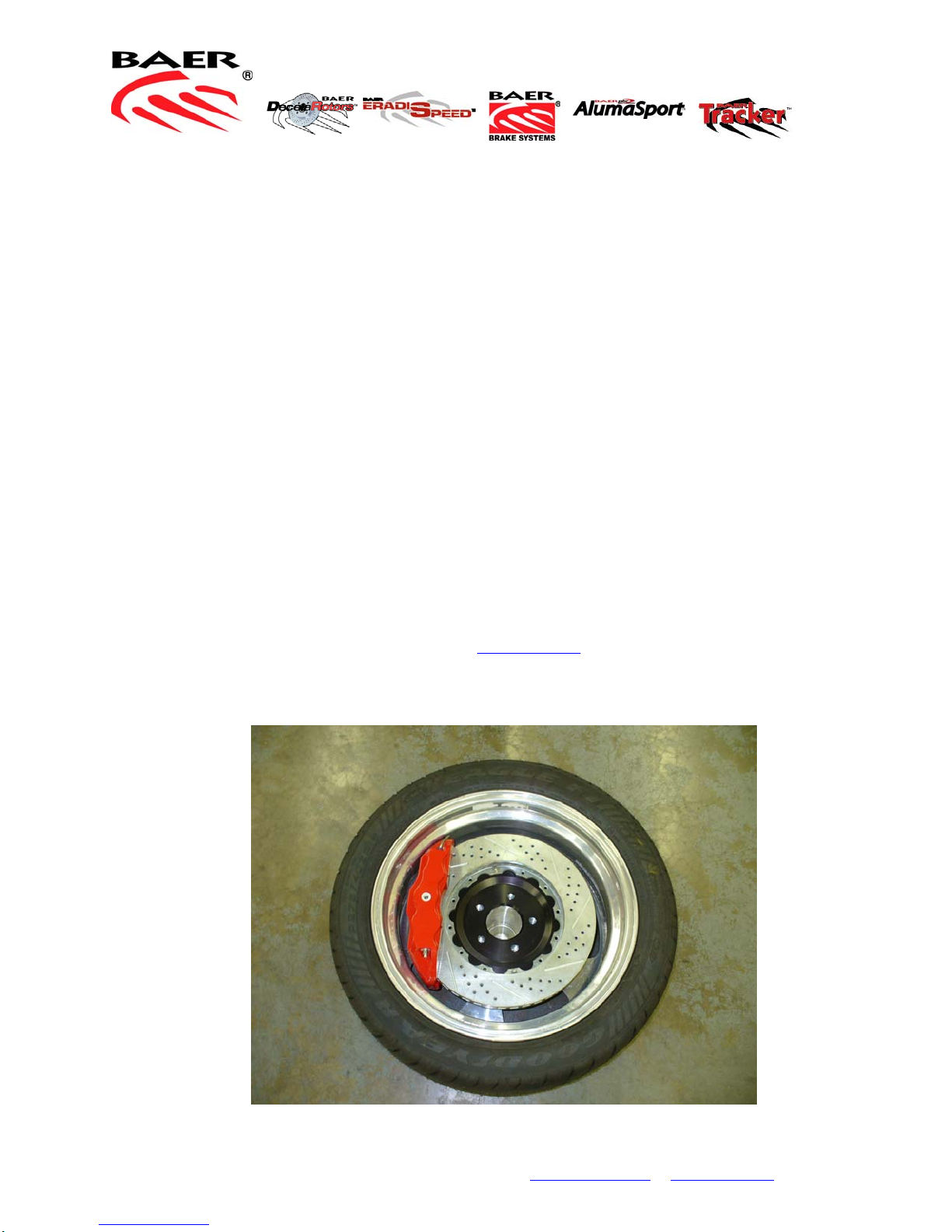

• ALWAYS CONFIRM WHEEL FIT PRIOR TO BEGINNING INSTALLATION OF ANY BRAKE

SYSTEM OR “UPSIZED” ROTOR UPGRADE! In addition to already having checked fit using the

Baer Brake Fit Templates available online at www.baer.com, always place the actual corner

assembly or a combination of the caliper assembly fit onto the rotor into the actual wheel to

reconfirm proper clearance is available between the caliper and the wheel before proceeding with

the actual installation.