GMC ZE06581 1976 Configuration guide

Other GMC Motorhome manuals

GMC

GMC 1975 Motorhome User manual

GMC

GMC 1976 TRANSMODE User manual

GMC

GMC Motor Home User manual

GMC

GMC 1973 Revcon User manual

GMC

GMC Royale User manual

GMC

GMC MotorHome User manual

GMC

GMC 1976 TRANSMODE User manual

GMC

GMC 1977 motorhome User manual

GMC

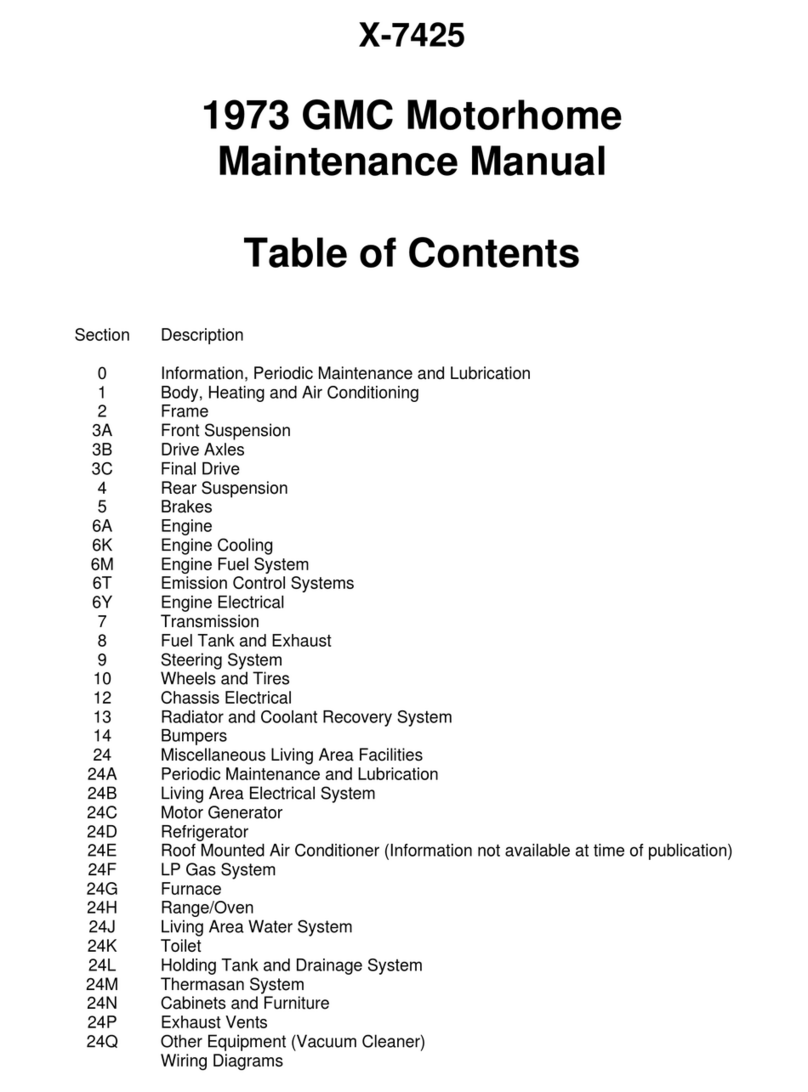

GMC X-7425 1973 User manual

GMC

GMC X-7425 1973 User manual

Popular Motorhome manuals by other brands

Jayco

Jayco Kiwi Travel Trailer 2003 owner's manual

Fleetwood

Fleetwood 1999 Discovery Parts and service manual

Bush Palace

Bush Palace STARCRAFT TOO user manual

Fleetwood

Fleetwood Jamboree Searcher 1993 user guide

Winnebago

Winnebago Journey Service manual

Tiffin Motorhomes

Tiffin Motorhomes 2017 Allegro Breeze owner's manual