D6072 - SIL 2 Multifunction Temperature Converter G.M. International ISM0216-5

8

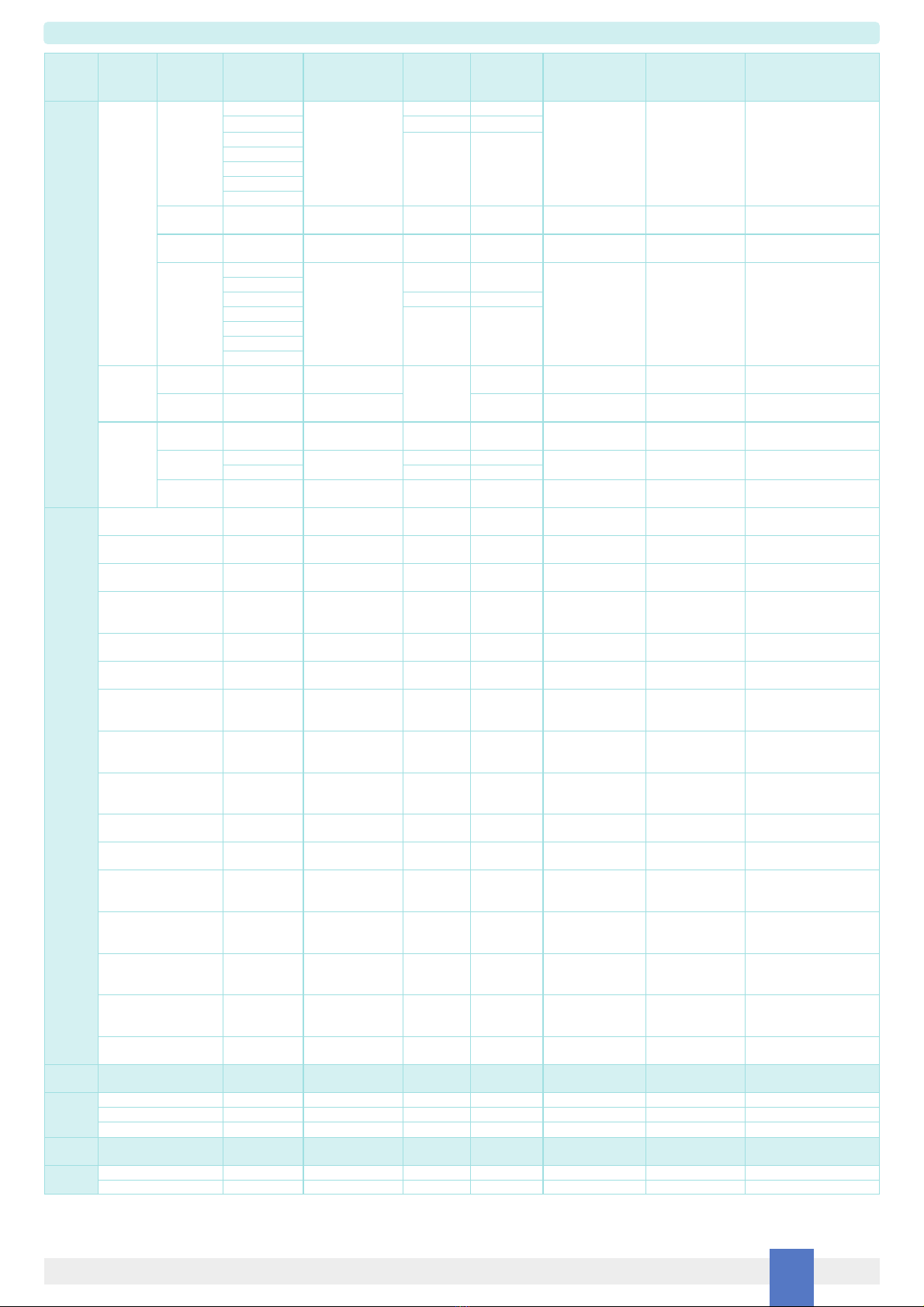

Supported Modbus functions:

Code Name Notes

03 read holding registers reads a stream of words from memory

04 read input registers reads a stream of words from memory

08 diagnostics: subcode 0 returns query data

06 write single register writes a word in memory

16 write multiple registers writes a stream of words in memory

Supported Modbus parameters:

The unit can communicate via Modbus RTU RS-485 protocol. Below is a list of all

available registers.

Each Modbus parameter is described by one 16-bit word.

- 'Addr.' is the address of the parameter.

- 'Description' explains the function of the parameter.

- 'Rights' identifies the operation that can be executed by the user:

RO (Read Only);

WO (Write Only);

RW (Read and Write).

- 'Type' indicates the kind of the variable:

SINT8 / UINT8: signed / unsigned 8 bits integer;

SINT16 / UINT16: signed / unsigned 16 bits integer;

SINT32 / UINT32: signed / unsigned 32 bits integer;

FLOAT: floating point single precision real;

DOUBLE: floating point double precision real;

the suffix '[n]' indicates an array of n elements of the corresponding type.

Addr. Description Rights Type

IDENTIFICATION

0 GM International code RO UINT16

1 Software revision RO UINT16

2 Product code RO UINT16

3 Option code RO UINT16

4 Hardware revision RO UINT16

COMMAND EXECUTION

100 Command (*1) WO UINT16

GENERAL CONFIGURATION

202 Fault on bus mask (*2) RW UINT32

MODBUS COMMUNICATION

300 Modbus address RW UINT16

301 Modbus baud-rate (*3) RW UINT16

302 Modbus format (*4) RW UINT16

GENERAL DEBUG

400 Time stamp [100ms] RO UINT32

404 Cumulative faults (*2) RO UINT32

TAG

700 Tag 1 RW UINT8[16]

708 Tag 2 RW UINT8[16]

OUTPUT CONFIGURATION

800 Input to analog out 1 function (*5) RW UINT16

801 Input to analog out 2 function (*5) RW UINT16

ALARM CONFIGURATION

803 Input to alarm 2 function (*5) RW UINT16

INPUT CONFIGURATION

804 Integration speed (*6) RW UINT16

900 Ch1: sensor family (*7) RW UINT16

901 Ch1: sensor connection (*8) RW UINT16

902 Ch1: sensor type (*9) RW UINT16

903 Ch1: sensor burnout configuration (*10) RW UINT16

904 Ch1: cold junction compensation (*11) RW UINT16

905 Ch1: cold junction external type (*9) RW UINT16

1000 Ch2: sensor family (*7) RW UINT16

1001 Ch2: sensor connection (*8) RW UINT16

1002 Ch2: sensor type (*9) RW UINT16

1003 Ch2: sensor burnout configuration (*10) RW UINT16

1004 Ch2: cold junction compensation (*11) RW UINT16

1005 Ch2: cold junction external type (*9) RW UINT16

1100 Ch1: cold junction fixed value [0.1°C] RW SINT32

1102 Ch1: 2-wire rtd correction [mOhm] RW SINT32

1104 Ch1: rtd multiplier RW FLOAT

1200 Ch2: cold junction fixed value [0.1°C] RW SINT32

1202 Ch2: 2-wire rtd correction [mOhm] RW SINT32

1204 Ch2: rtd multiplier RW FLOAT

1500 Ch1: sensor value (volt, res, ratio) [uV, mOhm,

ppm] RO SINT32

MEASURE

1502 Ch1: cold junction resistance value [mOhm] RO SINT32

1504 Ch1: sensor temperature [0.1°C] RO SINT32

1506 Ch1: cold junction temperature [0.1°C] RO SINT32

1600 Ch2: sensor value (volt, res, ratio) [uV, mOhm,

ppm] RO SINT32

Addr. Description Rights Type

1602 Ch2: cold junction resistance value [mOhm] RO SINT32

1604 Ch2: sensor temperature [0.1°C] RO SINT32

1606 Ch2: cold junction temperature [0.1°C] RO SINT32

OUTPUT CONFIGURATION

1900 Ch1: output downscale [100nA] RW SINT32

1902 Ch1: output upscale [100nA] RW SINT32

1904 Ch1: output underrange [100nA] RW SINT32

1906 Ch1: output overrange [100nA] RW SINT32

1908 Ch1: output in case of fault [100nA] RW SINT32

1910 Ch1: output fault mask (*2) RW UINT32

1916 Ch1: output damping factor [s] RW UINT32

1918 Ch1: input downscale [uV, mOhm, ppm] RW SINT32

1920 Ch1: input upscale [uV, mOhm, ppm] RW SINT32

2000 Ch2: output downscale [100nA] RW SINT32

2002 Ch2: output upscale [100nA] RW SINT32

2004 Ch2: output underrange [100nA] RW SINT32

2006 Ch2: output overrange [100nA] RW SINT32

2008 Ch2: output in case of fault [100nA] RW SINT32

2010 Ch2: output fault mask (*2) RW UINT32

2016 Ch2: output damping factor [s] RW UINT32

2018 Ch2: input downscale [uV, mOhm, ppm] RW SINT32

2020 Ch2: input upscale [uV, mOhm, ppm] RW SINT32

OUTPUT DEBUG

2302 Ch1: output virtual value [100nA] RO SINT32

2402 Ch2: output virtual value [100nA] RO SINT32

ALARM CONFIGURATION

2600 Ch2: alarm configuration (*13) RW UINT32

2604 Ch2: alarm start lock (*14) RW UINT32

2606 Ch2: contact position in case of alarm (*15) RW UINT32

2608 Ch2: alarm fault configuration (*16) RW UINT32

2610 Ch2: alarm fault mask (*2) RW UINT32

2612 Ch2: delay to alarm issue [ms] RW UINT32

2614 Ch2: delay to alarm removal [ms] RW UINT32

2616 Ch2: alarm low threshold [uV, mOhm, ppm] RW SINT32

2618 Ch2: alarm low threshold hysteresis [uV,

mOhm, ppm] RW SINT32

2620 Ch2: alarm high threshold [uV, mOhm, ppm] RW SINT32

2622 Ch2: alarm high threshold hysteresis [uV,

mOhm, ppm] RW SINT32

ALARM DEBUG

2806 Ch2: alarm virtual state (*17) RO UINT32

OUTPUT CONFIGURATION

2900 Ch1: output drive (*18) RW UINT16

3000 Ch2: output drive (*18) RW UINT16

3100 Callendar-van dusen coeff. A [1/°C] RW FLOAT

INPUT CONFIGURATION

3102 Callendar-van dusen coeff. B [1/°C2] RW FLOAT

3104 Callendar-van dusen coeff. C [1/°C4] RW FLOAT

3106 Callendar-van dusen res. at 0°C [mOhm] RW UINT32

3108 Table minimum temperature [0.1°C] RW SINT32

3110 Table maximum temperature [0.1°C] RW SINT32

3200 Sensor family (*7) RW UINT32

3202 Table minimum temperature [0.1°C] RW SINT32

3204 Table maximum temperature [0.1°C] RW SINT32

3206 Table temperature step [0.1°C] RW UINT32

3210 Custom sensor table [uV, mOhm] RW SINT32[100]