7

D1062 - Vibration Transducer InterfaceG.M. International ISM0094-7

D1062 is an isolated Intrinsically Safe Associated Apparatus installed into standard EN50022 T35 DIN Rail located in Safe Area/ Non Hazardous Locations or Zone 2, Group IIC,

Temperature Classification T4, Class I, Division 2, Groups A, B, C, D, Temperature Code T4 and Class I, Zone 2, Group IIC, IIB, IIA Temperature Code T4 Hazardous Area/Hazardous

Locations (according to EN/IEC60079-15, FM Class No. 3611, CSA-C22.2 No. 213-M1987, CSA-E60079-15) within the specified operating temperature limits Tamb -20 to +60 °C,

and connected to equipment with a maximum limit for AC power supply Um of 250 Vrms.

Non-incendive field wiring is not recognized by the Canadian Electrical Code, installation is permitted in the US only.

For installation of the unit in a Class I, Division 2 or Class I, Zone 2 location, the wiring between the control equipment and the D1062 associated apparatus shall be accomplished

via conduit connections or another acceptable Division 2, Zone 2 wiring method according to the NEC and the CEC.

Not to be connected to control equipment that uses or generates more than 250 Vrms or Vdc with respect to earth ground.

D1062 must be installed, operated and maintained only by qualified personnel, in accordance to the relevant national/international installation standards

(e.g. IEC/EN60079-14 Electrical apparatus for explosive gas atmospheres - Part 14: Electrical installations in hazardous areas (other than mines), BS 5345 Pt4, VDE 165,

ANSI/ISA RP12.06.01 Installation of Intrinsically Safe System for Hazardous (Classified) Locations, National Electrical Code NEC ANSI/NFPA 70 Section 504 and 505,

Canadian Electrical Code CEC) following the established installation rules, particular care shall be given to segregation and clear identification of I.S. conductors from non I.S. ones.

De-energize power source (turn off power supply voltage) before plug or unplug the terminal blocks when installed in Hazardous Area/Hazardous Locations or

unless area is known to be nonhazardous.

Warning: substitution of components may impair Intrinsic Safety and suitability for Division 2, Zone 2.

Explosion Hazard: to prevent ignition of flammable or combustible atmospheres, disconnect power before servicing or unless area is known to be nonhazardous.

Failure to properly installation or use of the equipment may risk to damage the unit or severe personal injury.

The unit cannot be repaired by the end user and must be returned to the manufacturer or his authorized representative. Any unauthorized modification must be avoided.

Warning

Operation

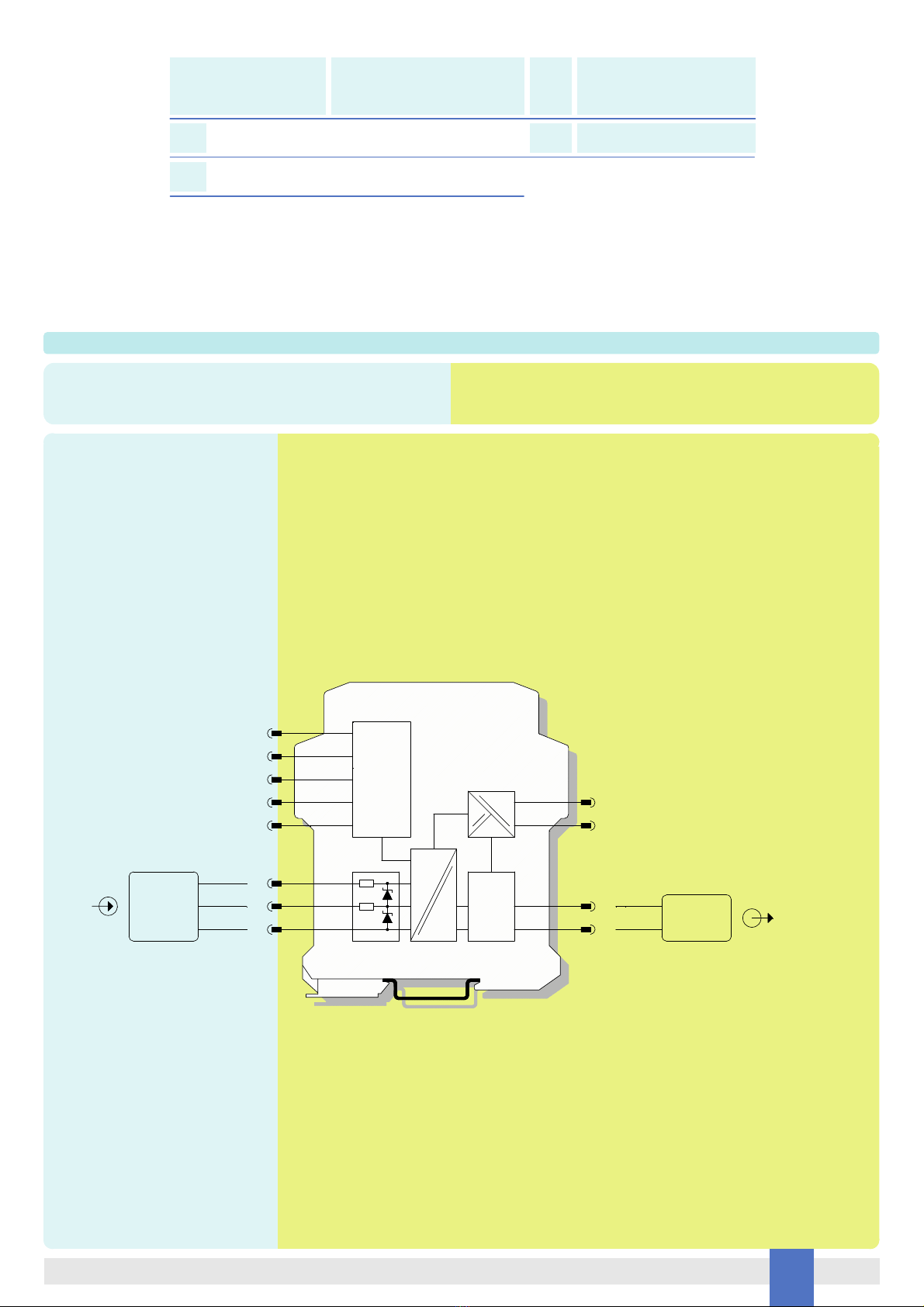

D1062 provides fully floating DC supply for energizing vibration transducer, accelerometers or 2-3 wires sensors located in Hazardous Area, and repeats the sensor input voltage in

a totally isolated circuit located in Safe Area to drive vibration monitors or analyzers for rotating machinery control and supervision purposes.

The circuit provides 3 port isolation (input / output / supply) and a “POWER ON” green led is lit when input power is present.

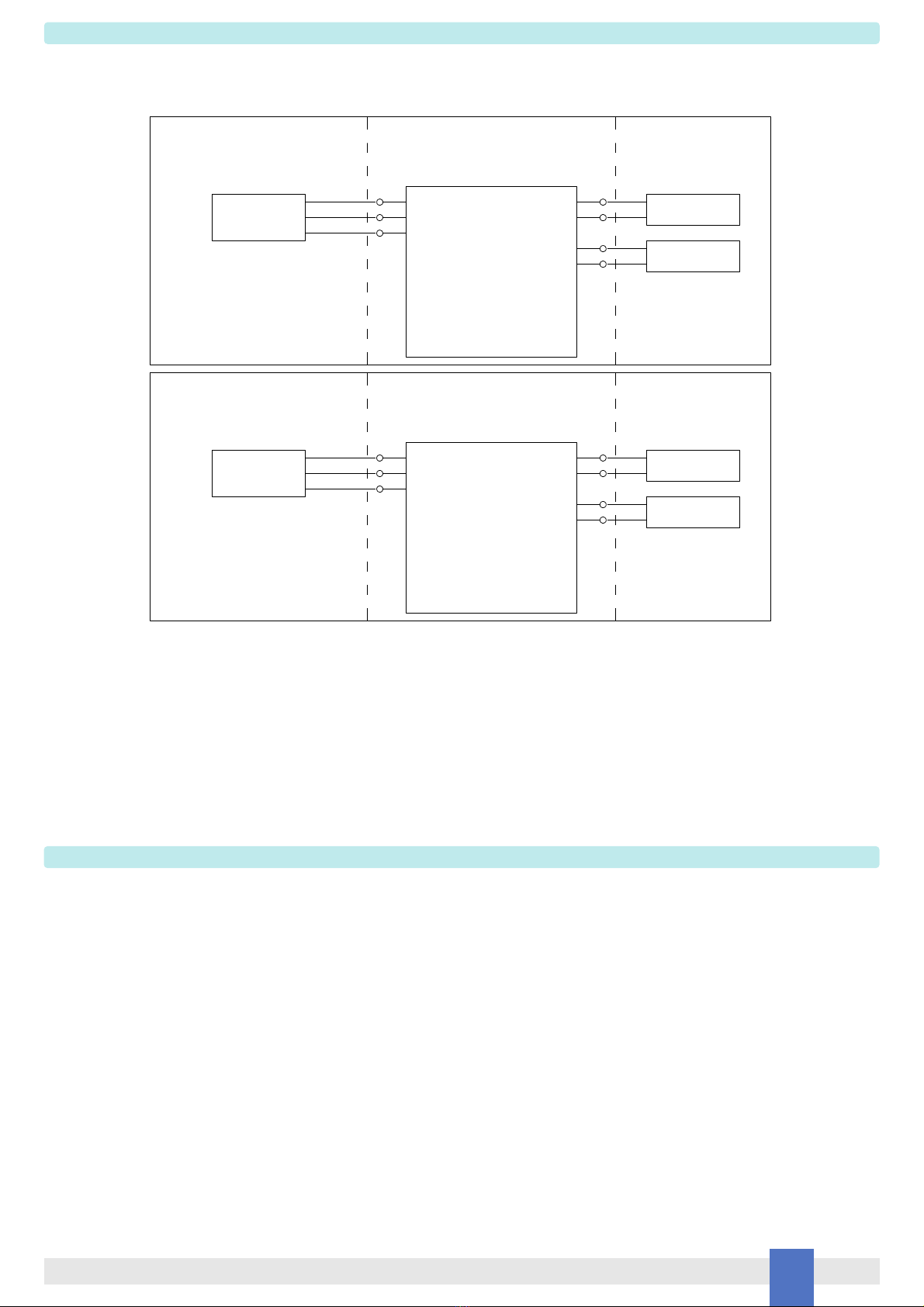

D1062 Associated Apparatus

FM Approved

under Entity Concept

and non-incendive field wiring

Unclassified Locations or

Hazardous (Classified) Locations

Class I, Division 2, Groups A, B, C, D, T-Code T4

Class I, Zone 2, Group IIC, IIB, IIA, T-Code T4

FM Approved under Entity Concept,

or third party approval

Hazardous (Classified) Locations

Class I, Division 1, Groups A, B, C, D

Class II, Division 1, Groups E, F, G

Class III, Division 1

Class I, Zone 0, Group IIC, IIB, IIA

Must not use or generate

more than 250 Vrms or Vdc

Unclassified Locations

Unclassified Locations or

Hazardous (Classified) Locations

Class I, Division 2, Groups A, B, C, D, T-Code T4

Class I, Zone 2, Group IIC, IIB, IIA, T-Code T4

Hazardous (Classified) Locations

Class I, Division 2, Groups A, B, C, D

Class II, Division 2, Groups E, F, G

Class III, Division 2

Class I, Zone 2, Group IIC, IIB, IIA

FM Approved under non-incendive field

wiring (permitted only for US installations),

or third party approval

Unclassified Locations

-

+

Power Supply

3

4

Must not use or generate

more than 250 Vrms or Vdc

D1062 Associated Apparatus

FM Approved

under Entity Concept

and non-incendive field wiring

2

1

-

-Control

Equipment

2-

4

3

-

+

1+Control

Equipment

Power Supply

Intrinsically

Safe Equipment

-

-

-

14

16

15

Non-Incendive

Equipment

-15

-16

-14