Page 2 of 4

www.gmptools.com General Machine Products (KT), LLC

This equipment should be used only by personnel who have been given the appropriate training

and who are competent to use it.

These instructions are to be made available to operators of this equipment at all times. Failure to

observe these safety instructions could result in serious personal injury and/or property damage.

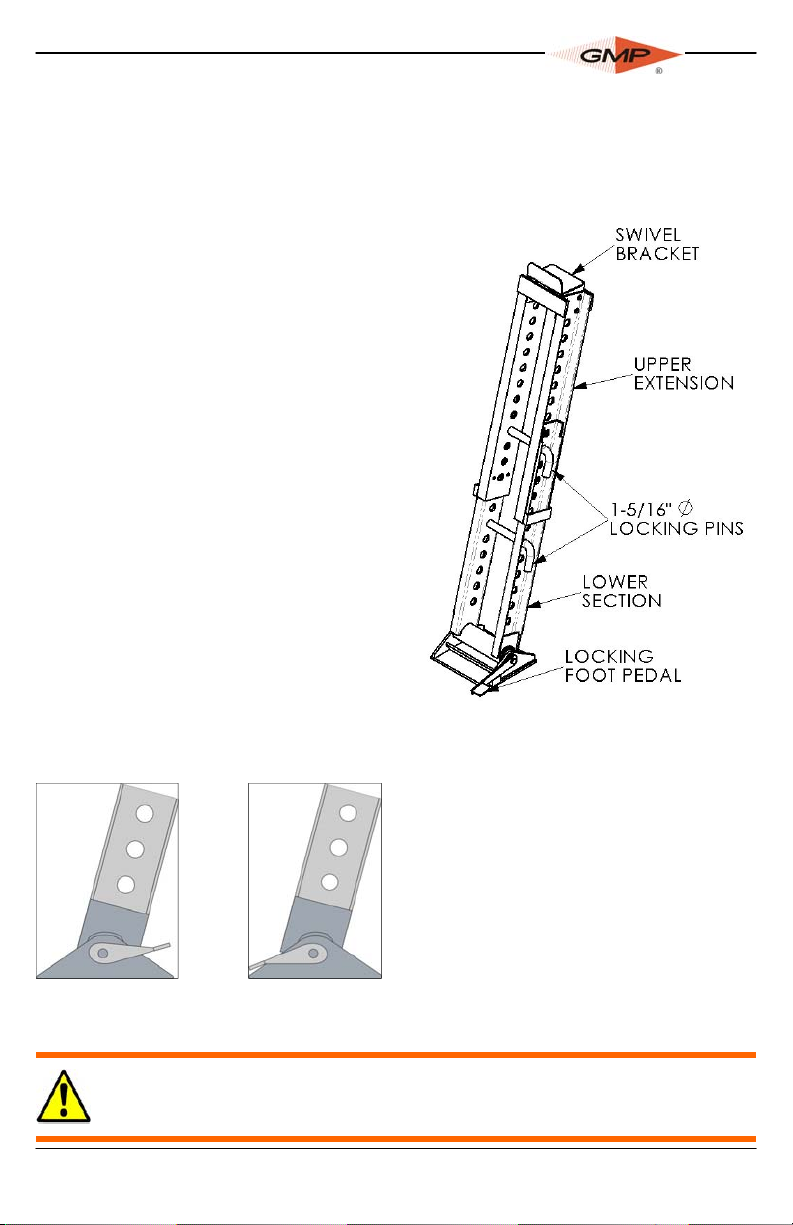

1. Lower the lower section of the Jam Skid into the manhole.

Rotate the locking foot pedal to the unlocked position

(figure A).

2. Align the center of the jam skid with the

center of the duct.

3. Lower the upper section into the man-

hole and install the upper section into

the lower section.

4. Raise the upper section so the swivel

bracket rests under the lip of the

manhole and the entire jam skid

rests at an angle of approximately

75° from the floor.

5. Install a locking pin to secure the 2

sections.

6. Using the 2nd locking pin install a

sheave or quadrant of suitable

size for the cable between the

jam skid legs and align with the

duct.

7. Secure the jam skid by moving

the base in or out slightly while

pressing down on the locking foot pedal until the locking

foot pedal fully engages (B).

unlocked

A

fully engaged

and locked

B

INSTALLATION

REMOVAL

1. Place leverage bar under

locking foot pedal and pry up

to release the Jamb Skid.

2. Remove the Jamb Skid by

reversing the installation pro-

cedure.