GMP Adams CD3 Owner's manual

1

Copyright 2018 by General Machine Products (KT), LLC

All rights reserved. No part of this publication may be copied, reproduced or transmitted in any form

whatsoever without the written permission of General Machine Products (KT), LLC

Adams Model CD3 & WG Rope Winder

INSTALLATION, OPERATION & MAINTENANCE

GMP • 3111 Old Lincoln Hwy • Trevose, PA 19053 • USA

TEL: +1-215-357-5500 • FAX: +1-215-357-6216 • EMAIL: www.gmptools.com

July 17 2018 USA Ver 2a

2General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

SECTION TABLE OF CONTENTS PAGE

1.0 GENERAL INFORMATION 3

2.0 DESCRIPTION 3

3.0 OPERATION 3

4.0 PLACING WIRE ROPE ONTO THE WINCH DRUM 4

5.0 ADJUSTMENT 5

6.0 LUBRICATION 6

7.0 SPROCKET AND CHAIN SELECTION 6

8.0 WIRE ROPE 7

9.0 WIRE ROPE LUBRICATION 8

10.0 REPAIR PARTS 8

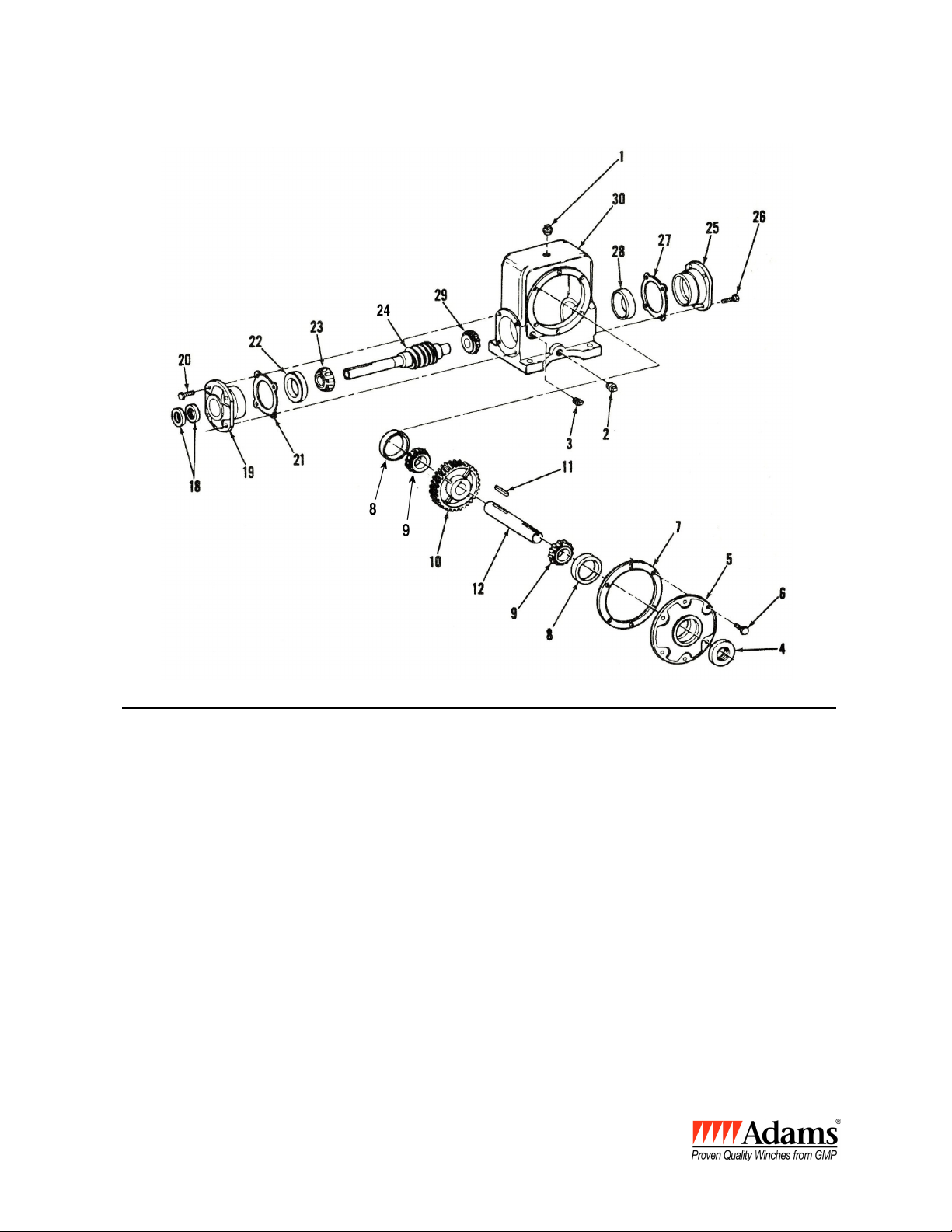

PARTS IDENTIFICATION DRAWING 9

PARTS LIST 10, 11

REDUCER ASSEMBLY INDENTIFICATION 12

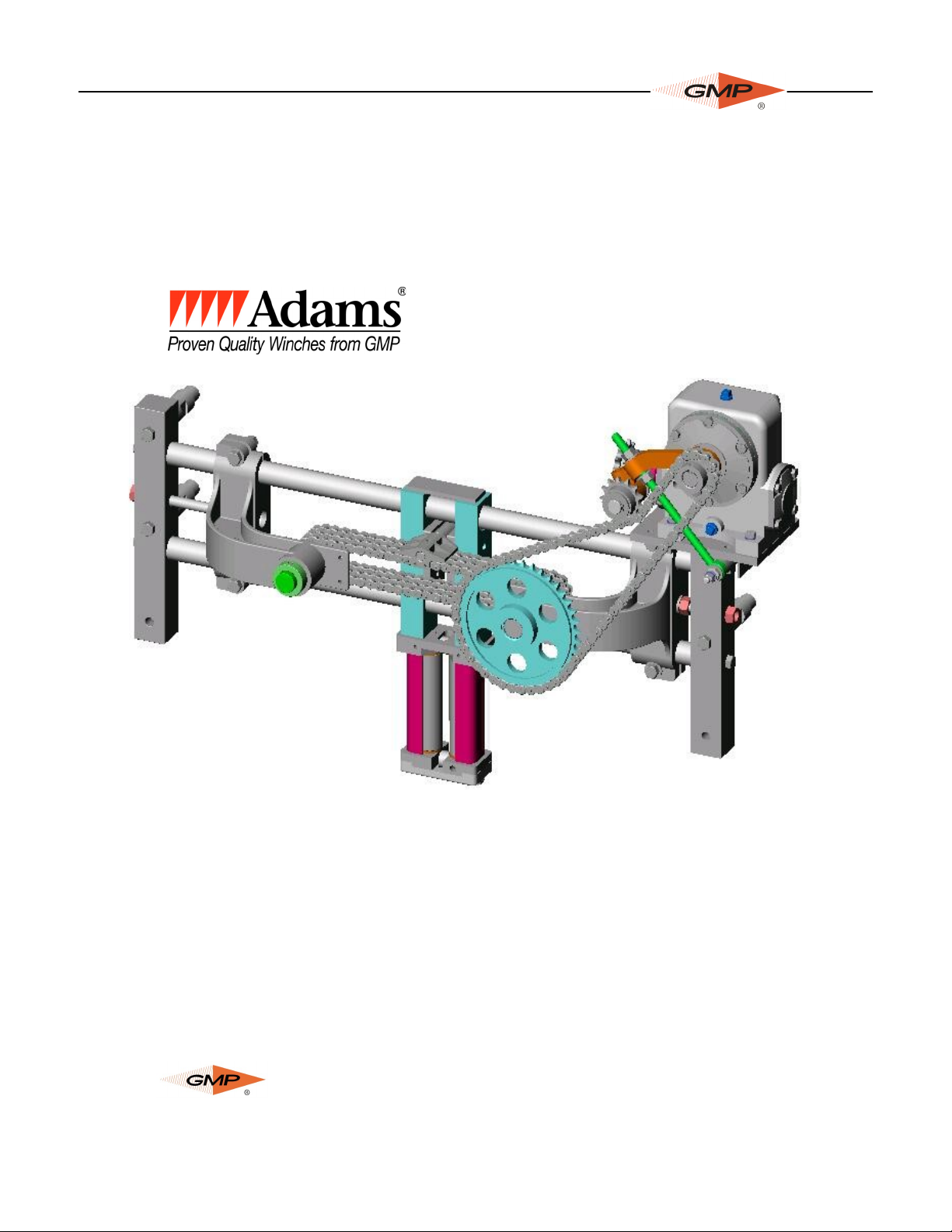

Cross Chain

Carriage/Roller Cage

Guide Bars

End Sprocket

Speed Reducer

Drive Pin

Figure 1

(Underwind Assembly Shown)

3

1. General Information

The Level Wind is a chain driven device specifically designed to distribute wire rope coils or

wraps evenly across the winch drum.

Level winding the wire rope onto the drum has several advantages:

● Increases drum storage capacity.

● Prevents wire rope pileup.

● Permits smooth, steady pulls.

● Establishes tight, even wraps preventing the wire rope from cutting down through the lower

lays resulting in damage to the rope and difficulty in unwinding.

2. Description

The level wind assembly includes a carriage/roller cage, guide bars, speed reducer, two single

width and one triple width roller chain drive.

The carriage is mounted on two guide bars and is driven side to side across the drum by an end-

less triple width cross chain (See Figure 1 on page 2).

The carriage is connected to the cross chain by a drive pin which projects into a vertical slot in

the carriage. As the cross chain rotates, it carries the drive pin and the carriage across the drum.

When the drive pin reaches the end sprocket, it rotates around the sprocket moving up or down

in the slot as required. Accordingly, the carriage and wire rope moves to the end of its travel and

starts back again across the drum.

Positioned above the carriage (or below in the under wind configuration) is the roller cage as-

sembly thru which the wire rope passes for final storage on the drum. The rollers are shielded

with a roller guard for the purpose of operational safety.

3. Operation

The level wind is mechanically driven from the motion of the winch drum. Use caution to maintain

uniformity and compactness of the wraps and lays of the wire rope on the drum at the start of the

pull.

The carriage remains properly aligned because the level wind is mechanically driven directly

from the winch drum. This is true of whether the rope is paying onto the drum under power or

paying out under free spool conditions.

The speed of the carriage is regulated. For each revolution of the winch drum, the carriage ad-

vances across the drum a distance equal to the diameter of the rope.

Initially, the correct sprockets are determined by the factory relative to the nominal cable size

that is specified for the winch. Due to minor variations in the diameter of the wire rope, the aver-

age diameter may have to be determined in order to modify the speed of the rope winder. Take

several diameter measurements along the length of the wire rope, and call GMP to determine

the correct sprocket combination.

Once a given set of sprockets has been established for a specific wire rope diameter, the rope

diameter cannot be changed without a change in the sprocket teeth combination.

Constant tension must be maintained on the rope when operating the level wind. The

amount of tension should be sufficient to eliminate “clock springing” that will lead to loose or tan-

gled wraps and lays.

Under free spool conditions, if the drum has been permitted to over-run, resulting in loose or tan-

4General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

gled wraps, remove several feet of improperly wrapped rope and rewind, under tension, prior to

starting the actual pull. To insure good operation, the wraps and lays must always be straight

and compact.

The winch is furnished with a caliper type drag brake. The brake is not designed to hold the load.

The purpose of the brake is to control the drum rotation speed when paying out wire rope under

free spool conditions. Slowing down and gradually stopping the drum, with tension on the rope,

will prevent backlash, clock-springing and eventual entanglement of the rope.

For safety and convenience, the drag brake is equipped with a remote actuator. The remote ac-

tuator, reservoir and flexible hose section are shipped loose in the parts box. These components

are to be installed by the dealer.

Although the level wind will guide the wire rope onto the drum from a relatively wide fleet angle,

there will be less bending of the rope at the roller cage assembly if the line of pull is as straight

as possible. Therefore, the use of a universal or universal swivel sheave on the tail shelf is advis-

able.

The roller cage assembly has only a sufficient amount of clearance for the rope to pass. When

pulling in the wire rope, it is important that the operator stops the drum rotation at a point to keep

the spliced eye or quick hook several feet from the roller cage. Otherwise, the eye and hook will

be drawn into the roller cage, causing damage to the level wind.

If, for any reason, it is necessary to remove the wire rope from the roller cage while at a mid-

point in the rope, it can be done by removing the roller cage top plate. First, remove the (2) hex

bolts on the roller cage top plate then remove the top plate. Loosen the (2) set screws on either

side of the mounting plate and remove the roller guide. The rope is then free.

4. Placing Wire Rope Onto The Winch Drum

Note: See section 8.0 for additional details on wire rope.

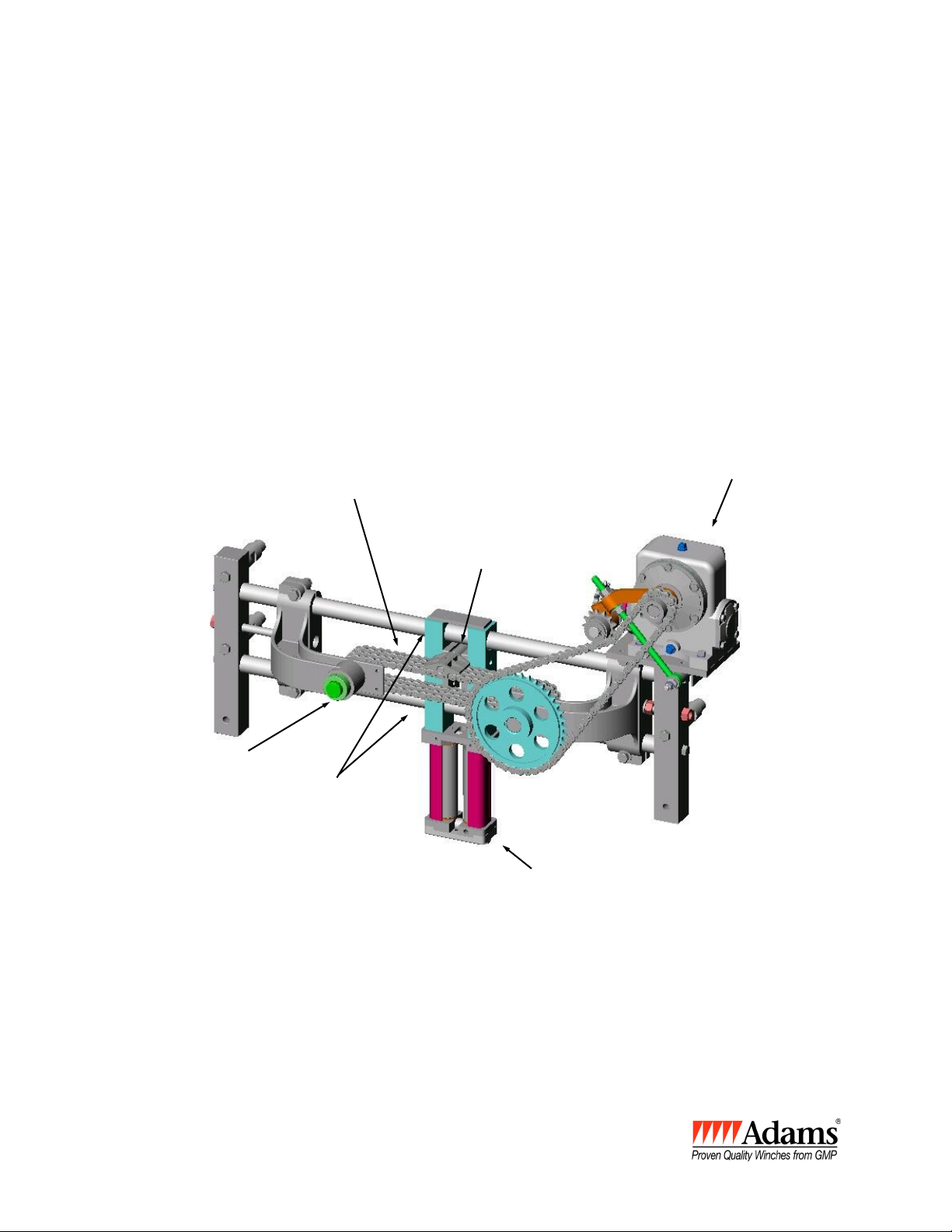

The timing of the level wind must be set properly when placing rope onto the drum. Set the tim-

ing of the level wind by rotating the drum until the carriage reaches a position of maximum travel

at the drum end where the rope is to be attached. The extreme end of the carriage travel is when

the guide link is on the outside of the end sprocket and at the mid-point of the vertical slot in the

carriage. Thread the end of the rope through the roller cage and attach it to the drum by means

of the rope clamp. See figure 2. Drive the winch forward at a low speed, keeping sufficient ten-

sion on the rope. It is extremely important that the first lay of rope be straight and compact. Slow-

ly increase the drum speed and spool on the remaining rope.

Whenever possible, a winch line holder should be used to prevent the rope from unwinding.

5. Adjustment

The speed reducer input and

The carriage at the

maximum travel position

Figure 2.

5

output single width roller chain drives should be tight enough to prevent backlash but not exces-

sively tight to cause bending of the reducer shafts. Special care should be taken when adjusting the

first reduction chain. Rotate the drum (with the chain loose), to the point where the chain is at its

tightest (its high spot). Adjust the chain idler to about 1/2 inch deflection in the chain. Next, rotate

the drum a full turn to insure that the chain doesn’t get tighter than the 1/2 in. deflection. A 1st re-

duction chain that’s too tight will permanently bend the input shaft.

The triple width cross chain should be sufficiently tight to prevent tipping of the guide link. Any un-

steady movement of the carriage could indicate a loose cross chain or lack of lubrication on the

guide bars.

The cross chain should be adjusted an equal amount at both ends by the corresponding adjusting

screw. The distance from the back of the chain to the inside of the drum must be equally spaced.

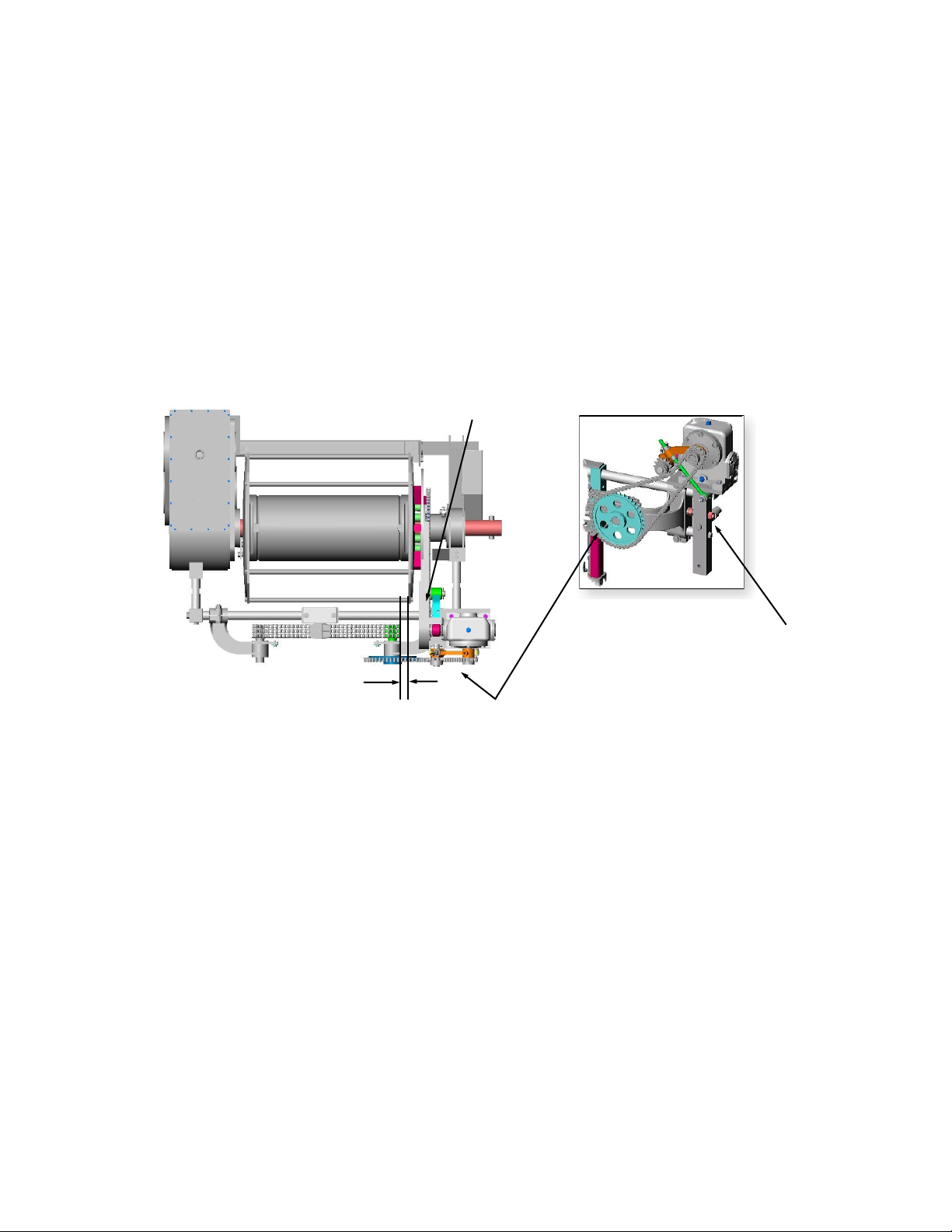

See Figure 3.

The front chain drive (2nd reduction) from the speed reducer must be loosened before

any adjustment is made to the cross chain.

Rotate the drum one revolution taking a measurement at four locations to check for equal spacing.

Checking in four locations will compensate for any distortion in the drum flanges. Shift the cross

chain assembly by turning the adjusting screws at each end after the lock nuts have been loosened.

If the rope piles up at one end and leaves an opening at the other end, shift the cross chain slightly

away from the end where the rope piles up

The cross chain length is for an average drum width. If the rope piles up at both ends of the drum,

the cross travel speed is too slow, or the cross chain length is too long. Remove one pitch from the

cross chain and check for rope pileup at the ends of the drum. Make further adjustments to the cross

chain length by removing additional links if necessary.

If the rope leaves an opening at both ends of the drum, the cross chain length is too short. Add one

pitch to the cross chain and check for openings at the ends of the drum. Add additional links if nec-

essary.

6. Lubrication

Every 3 months or seventy five (75) hours of operation, the level wind assembly should be lubricat-

ed in accordance with the instructions shown on figure 4.

Use standard motor oil in four oil cups marked “C”, three roller chains (lubricated on the inside sur-

Figure 3.

1st Reduction Chain

2nd Reduction Chain

Maintain equal distance on

both sides of cross chain

Adjusting Screws

6General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

face of the chain) coat the guide bars with a rust inhibitor such as LPS 3 Premier rust inhibitor or

equivalent. Reapply the rust inhibitor to prevent corrosion once every month.

To check for the proper oil level in the speed reducer, remove the oil level plug in the side of the

housing, lubricant should be maintained to the height of the oil level opening. Fill to the proper oil

level with 80W140 oil or equivalent

To add oil, remove the oil level plug in the side of the housing. Remove the oil filler plug at the top

of the housing. Add oil to the height of the oil level opening. Be sure to replace the plug at the top

and on the side of the housing.

7.

Sprocket And Chain Selection

As previously specified, the number of teeth in the roller chain sprockets and the

length of chain is fixed depending on the specific rope diameter being used.

NOTE:

● The WG winch is designed to accept 7/16” diameter wire rope only.

● American produced wire rope is never smaller than the nominal diameter, always larger with

a plus tolerance of 1/32” in the size range used on GMP Adams Winches. Some foreign

product may be smaller.

● Should synchronization difficulty be experienced with standard sprockets, measure the diam-

eter of the wire rope in three locations with a micrometer and contact GMP.

● Sprockets and chains are 5/8” pitch, single width roller chain for the 1st and 2nd reduction.

● Sprockets and chains are 5/8” pitch, triple width roller chain for the cross chain.

● For the location of sprockets and chains see drawing on page 10.

To change the sprocket ratio to adjust for rope diameter tolerances,

1. Measure the wire rope in three different locations using a micrometer.

2. Contact GMP at 215-357-5500 and provide the wire rope diameter so the proper sprockets can

be determined.

3. Follow the following procedure after the sprockets are received.

Guide Bars

Cross Chain 2nd Reduction

Chain

1st Reduction

Chain

C

Check lubricant

level in gear

box. Fill to level

plug using

80W140 oil or

equivalent

C

Figure 4.

7

4. Remove the chain guards from the sprocket(s) to be changed. Be careful to not lose the hard-

ware.

5. To loosen the chain loosen the jam nuts on the idler adjustment shaft.

6. Remove the chain connector and remove the chain from the sprocket(s) to be removed.

7. Loosen the set screw on the sprocket and remove the sprocket. Take note of the direction the

hub is mounted on the shaft. Be careful not to lose the key.

8. Place new sprocket on the shaft with the key in the keyway in the shaft.

9. Align the new sprocket(s) by placing a straight edge on the sprockets to align them with each

other.

10. Tighten the set screw on the new sprocket and the jam nuts on the idler sprocket adjustment

shaft.

11. Place the chain on the sprocket and add chain connector.

12. Adjust the idler sprocket to take up any slack in the chain. Check the tension in the chain by ro-

tating the drum by hand one complete revolution. Be careful not to over tighten the chain. There

should be at least 1/2 in. slack at it’s loosest position.

13. Replace the chain guards.

14. Set the timing of the level wind carriage by rotating the drum until the rope clamp is at the 12 to

1 o’clock position (6 to 7 o’clock for under-wind) when viewing the drum from the right side.

15. Position the carriage at a position of maximum travel at the drum end where the rope is to be

attached. The extreme end of the carriage travel is when the guide link is on the outside of the

end sprocket and at the mid-point of the vertical slot in the carriage.

16. Thread the end of the rope through the roller cage and attach it to the drum by means of the

rope clamp. See figure 2.

17. Drive the winch forward at a low speed, keeping sufficient tension on the rope. It is extremely

important that the first lay of rope be straight and compact. Slowly increase the drum speed and

spool on the remaining rope.

Whenever possible, a winch line holder should be used to prevent the rope from unwinding.

8. Wire Rope

8.1 Spooling

● When installing the wire rope observe the following recommendations: It is important to select

the correct winch rope for a particular application. Wire rope is specified by length, diameter,

number of strands, number of wires per strand, type of center and type of lay. The purpose is

to stress the importance of selecting the correct type of lay.

● There is a definite advantage in applying wire rope of the proper direction of lay when spooling

onto the smooth surface of the winch drum. A rope with an improper lay may cause the coils

will spread apart each time the load is removed. Installing the wire rope with the proper lay will

tend to keep the coils together when the load tension is removed. The correct lay will develop

tight coils and even layers.

● It is important to install the wire rope onto the winch drum with care. Kinking of the rope,

caused by the rope taking a spiral shape as a result of an unnatural twist, should be avoided.

● When removing wire rope from the reel and spooling onto the winch drum, the reel must be

supported on a horizontal axis and free to rotate. Spool the rope onto the drum with the natu-

ral bend in the same direction as it comes off the reel.

● If wire rope is received in a coil, it should be unwound with the coil in the vertical plane. Again,

spool the rope onto the winch drum with the natural bend in the same direction as it was on

the coil. Reverse bending of the wire rope should always be avoided or kept to a minimum.

IMPORTANT! Wire rope should always be under tension when spooling onto the winch drum.

● When the winch drum is in free spool and the drum shaft extension only is being used with a

capstan or reel, pass the winch line through the tail shelf sheave and hook the pulling eye to a

fixed section of the chassis. This will prevent the rope from unwinding or “clock-springing.”

● Likewise, when the winch is not in operation, attach the winch line quick hook to a solid mem-

ber on the tail shelf and slowly take up the slack. This will best maintain the rope under a

General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 9053-4996 USA 215-357-5500

8General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

slight amount of tension until required again and will prevent the rope from unwinding or “clock

-springing.”

8.2 Winch drum rotation:

Note: The CD3 is available in an UNDER WIND and OVER WIND configuration

The WG winch is only available in an UNDER WIND configuration.

Over winding – is when the winch drum rotates in a clockwise direction (viewing from the right

side) and the wire rope is spooled onto the winch drum at the top. It is imperative that the wire

rope be attached to the correct side of the drum for the specific direction of the lay of the rope

given the direction of drum rotation. When the drum will be over winding as the wire rope is

spooled in, use the rope clamp on the side of the drum which is the same as the lay of the wire

rope. For example, if using right lay rope on an over wind drum attach the wire rope to the right

side rope clamp.

Under winding – is when the winch drum rotates in a counterclockwise direction (viewing from

the right side) and the wire rope is spooled onto the winch drum at the bottom. Once again, it is

imperative that the wire rope be attached to the correct side of the drum for the specific direction

of the lay of the rope given the direction of drum rotation. When the drum will be under winding

as the wire rope is spooled in, use the rope clamp on the side of the drum which is opposite of

the lay of the wire rope. For example, if using right lay rope on an under wind drum attach the

wire rope to the left side rope clamp.

The wire rope must be guided and maintained as it is routed forward under the body deck to the

winch drum. This can be done by using a trough or tube with sufficient width at the front and

depending on the angle of incline combined with the body cross-member configuration, a float-

ing sheave or roller may be required. Application engineering assistance is available from GMP.

WARNING! The cable clamp alone is not designed to hold the rated load. Approximately ½ of the

first layer of winch line must be left on the drum to achieve the rated load and avoid

cable clamp failure.

9 Lubrication:

● Wire rope is considered to be a machine, having many moving parts. Each time the rope

bends or flexes, the various wires and strands slide over each other. Lubrication is required

to facilitate this movement.

● The type of lubricant, method of applying and frequency of application is dependent on each

particular circumstance. For specific lubrication details contact the wire rope manufacturer.

10 Repair Parts:

● For item location, refer to Page 9.

● For part identification refer to parts list on Pages 10 thru 12.

9

10 General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

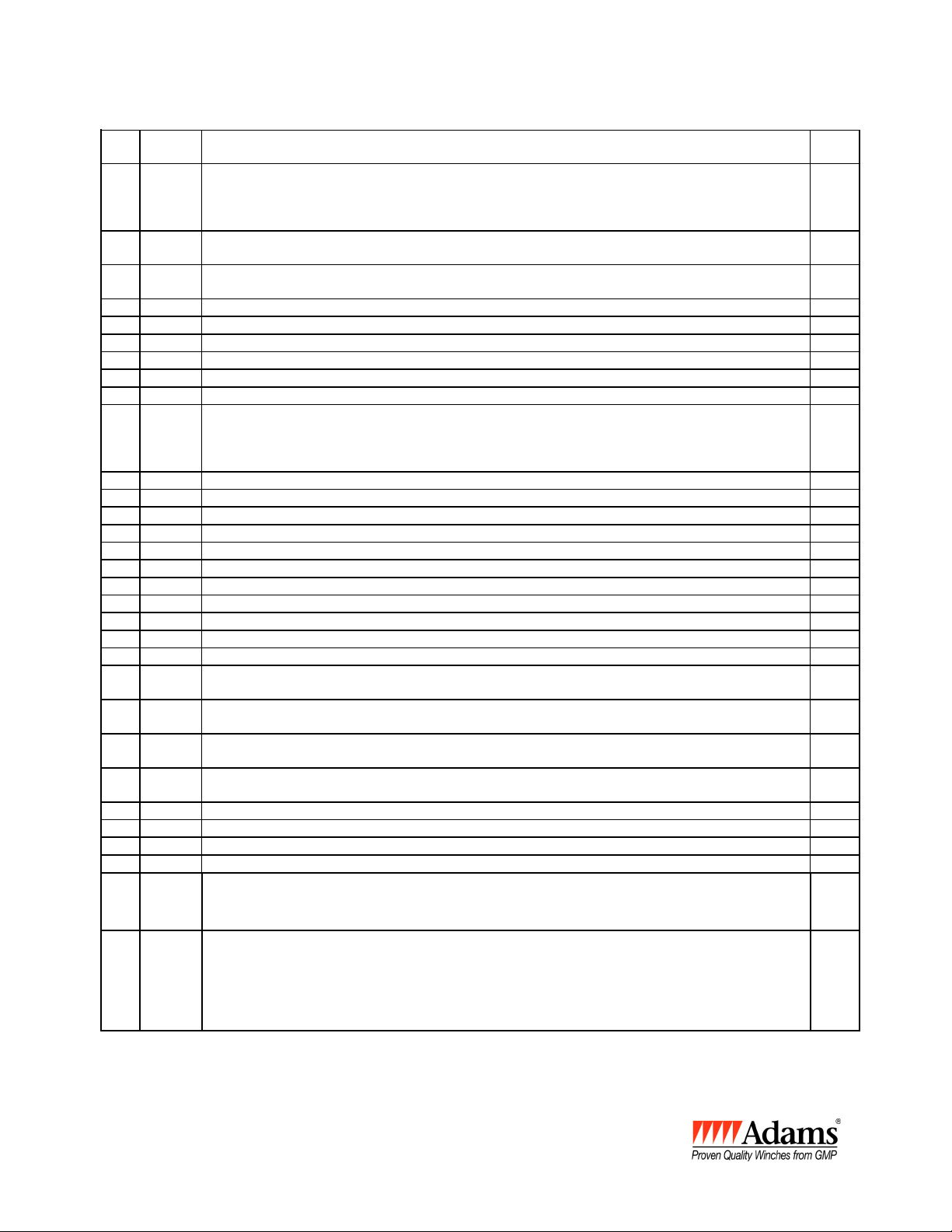

Item

No.

Part

No.

Description

Req’d

Qty.

126459

26460

Carriage assembly (CD3 over wind, WG over and under wind)

Includes items 2A, 3A, 4, 5, 6 Assy

Carriage assembly (CD3 under wind)

Includes items 2A, 3A, 4, 5, 6 Assy

1

1

225869

25870

Roller Assembly (WG, CD3 over wind)

Roller Assembly (CD3 under wind only)

2

2

325858

25862

Shaft (WG, CD3 over wind)

Shaft (CD3 under wind only)

2

2

425848 Guide Roller 1

525850 Shaft Guide Roller 1

609983 Roll pin 1/4” x 2” Long 2

714926 Guide Plate 2

816755 Cap Screw Hex Hd 3/8-24 x 2” Long 4

916449 3/8” Lock washer SAE medium 4

10 29764

34336

WG Cross Chain Assembly 5/8 Pitch 60 Pitches Triple

Width Roller Chain, Includes Items 11 & 12

CD3 Cross Chain Assembly 5/8 Pitch 74 Pitches Triple

Width Roller Chain, Includes Items 11 & 12

1

1

11 14952 Guide Link 1

12 14951 Connecting Pin 2

13 14927 Driving Pin 1

14 16938 Cap Screw Hex Head 1/2-20 x 2 ½”4

15 17591 Nut Hex 1/2-20 4

16 09324 1/2” Lock Washer SAE medium 5

17 17575 Nut Jam Steel 1/2-13 3

18 16762 Collar W/Set Screw 1

19 15585 Bracket Assembly w/Item 21 2

20 Same as item #19

21 16723 Bushing Oilite For Item 19 2

22 14949

14972

Sprocket w/Set screw 40 Teeth for 7/16”, 1/2” wire rope

Sprocket w/Set screw 36 Teeth for 5/16”, 3/8”, 9/16” wire rope

1

23 14925 Sprocket 10 Teeth, 5/8” Pitch Triple Width

Roller Chain, Short

1

24 14924 Sprocket 10 Teeth, 5/8” Pitch Triple Width

Roller Chain, Long with keyway

1

25 16734 Woodruff Key 5/16” x 1”

For Items 22 & 24

1 EA.

26 14973 Washer, Thrust (spacer) 2

27 09043 Nut, Jam 5/8”-18 2

28 17837 Cap Screw Hex Head 1/2-20 x 1 ¾”10

29 26061 Guide Rod Support 1

30 14915

24211

Sprocket (Replacement) For Winch Drum 58 Teeth

5/8” Pitch Roller Chain

Sprocket as above split for replacement on mounted winch. Must be welded in place

1

1

31 15593 Idler Bracket Assembly Second Reduction

Includes:

1 #14965 230-1003 Idler Bracket

2 #16724 110B Oil Cup

1 #16746 AA1110-12 Bushing Oilite

1 #16747 AA1108-16 Bushing Oilite

1

Refer to Drawing # 30435 on Page 9

11

Item

No.

Part

No.

Description

Req’d

Qty.

32 16744 Idler Adjusting Rod 1

33 09794 1/2” Washer Flat 1

34 14962 Sprocket Idler 13 Teeth 5/8” Pitch Roller Chain

With Set Screw

2

35 15594 Idler Shaft Assembly Includes:

1 #14966 230-1541 Idler Shaft

2 #16748 5160-87 Snap Ring

1 #16749 7/8” ID x 1 3/4” OD x .15 Thick Flat Washer

2

36 15591 Idler Bracket Assembly First Reduction Includes:

1 #14961 141-S-96 Idler Bracket

2 #16724 110-B Oil Cup

1 #16743 A1106-3 Bushing Oilite

1 #16742 A1108-10 Bushing Oilite

1

37 17888 Square Head Round Point Set Screw

1/2”-13 x 4” Long

1

38 16760

16738

16892

16766

First Reduction Driven Sprocket, 14 Teeth With Set Screw for 1/2”, 9/16” wire rope

First Reduction Driven Sprocket, 16 Teeth With Set Screw for 7/16” wire rope

First Reduction Driven Sprocket, 19 Teeth With Set Screw for 3/8” wire rope

First Reduction Driven Sprocket, 23 Teeth With Set Screw for 5/16” wire rope

1

39 17839 Key 3/16” Square x 1” Long 1

40 16767

16739

Second Reduction Drive Sprocket, 11 Teeth With Set Screw for 5/16”, 3/8” wire rope

Second Reduction Drive Sprocket, 12 Teeth With Set Screw for 7/16”, 1/2”, 9/16” wire rope

1

16751 Key 1/4” Square x 1” Long 1

42 28818

26295

Cross Chain Guard 19” drum WG

Cross Chain Guard drum CD3

1

43 28785

26132

Support Shaft Level wind – Hanger Side WG

Support Shaft Level wind – Hanger Side CD3

2

2

44 14967 Second Reduction 5/8” Roller Chain: 80 Pitches Includes Connection Link. 1

45 16727 Cap Screw Hex Head 5/16-24 x ¾” Long 4

46 05040 5/16” Lock Washer SAE Medium 4

47 02244 3/8” Flat Washer 4

48 14963 Stud 1

49 25236

25235

1st Reduction Roller Chain: 107 Pitches Includes Connecting Link. (WG, CD3 under wind)

1st Reduction Roller Chain: 97 Pitches Includes Connecting Link. (CD3 over wind)

1

50 26065 Pedestal Rod Support 1

51 28785

26131

Support Shaft Level wind - WG Housing

Support Shaft Level wind - CD3 Housing

2

2

52 14969 Chain Guard Second Reduction With Brackets -WG, CD3 1

53 28310 Chain Guard First Reduction With Brackets WG, CD3 1

54 14964 Reducer Assembly Right-Hand 1

55 28817

26074

Tie Rod Level Wind WG

Tie Rod Level Wind CD3

2

2

56 30286 Adjusting Rod 4” Long (1 per WG) (2 per CD3) AR

56 28822 Adjusting Rod 7” Long -Housing Side - (1 per WG ) (not used on CD3) AR

#28777 Mounting Weldment Level Wind LH - WG 1

#28782 Mounting Weldment Level Wind RH- WG 1

Refer to Drawing # 30435 on Page 9

12 General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

Item # Part # Description Qty. Item # Part # Description Qty.

115982 Plug, Breather 117 xx Not used

216442 Plug, Drain 118 16447 Seal, Oil 2

316888 Plug, Oil 119 15975 Carrier, Open Bearing 1

416448 Seal, Oil 120 16033 Bolt, Hex Hd 5/16-18x3/4 4

515976 Carrier, Open Bearing 121 17140 Gasket, Shim .005 (blue) AR

616033 Bolt, Hex Hd 5/16-18x3/4 621 15980 Gasket, Shim .020 (yellow) AR

715981 Gasket AR 22 16446 Cup 1

816445 Cup 223 16444 Cone 1

916443 Cone 224 15965 Shaft, Worm 1

10 15977 Gear, Worm 125 15973 Carrier, Closed Bearing 1

11 15978 Key 126 16033 Bolt, Hex Hd 5/16-18x3/4 4

12 15979 Shaft, Worm Gear 127 17140 Gasket, Shim .005 (blue) AR

13 xx Not used 27 15980 Gasket, Shim .020 (yellow) AR

14 xx Not used 28 16446 Cup 1

15 xx Not used 29 16444 Cone 1

16 xx Not used 30 15974 Housing 1

Winch Rope Winder Reducer Assembly

13

The GMP Limited Warranty can be found at http://www.gmptools.com/warranty/

14 General Machine Products Co. Inc.

3111 Old Lincoln Highway Trevose, PA 19053 USA 215-357-5500

General Machine Products (KT), LLC

3111 Old Lincoln Highway

Trevose, PA 19053 USA

TEL: 215-357-5500

FAX: 215-357-6216

E-MAIL: [email protected]

WEB: http://www.GMPtools.com

GMP reserves the right, without notice, to make changes in

equipment design or components as progress in engineering or

manufacturing methods may warrant.

All contents ©2012 GMP

This manual suits for next models

1

Table of contents

Other GMP Winch manuals

Popular Winch manuals by other brands

Monzana

Monzana DBSW003 instructions

Harken

Harken 42.2 Parts and Installation Service

Thern

Thern 465 owner's manual

Gude

Gude GSZ 200/400 Translation of original operating instructions

Northern Tool

Northern Tool NWB3000 Assembly & operating instructions

Trail-Gear

Trail-Gear DURALINE Series Install instructions

Harken

Harken 70.3 ST EL Installation and maintenance manual

Gigglepin

Gigglepin GP25 owner's manual

Harken

Harken 16st Parts, Installation and service

Ronstan

Ronstan Andersen 18ST FS product manual

American Landmaster

American Landmaster 17153 installation instructions

TUNGSTEN

TUNGSTEN T Series Installation and operator's manual