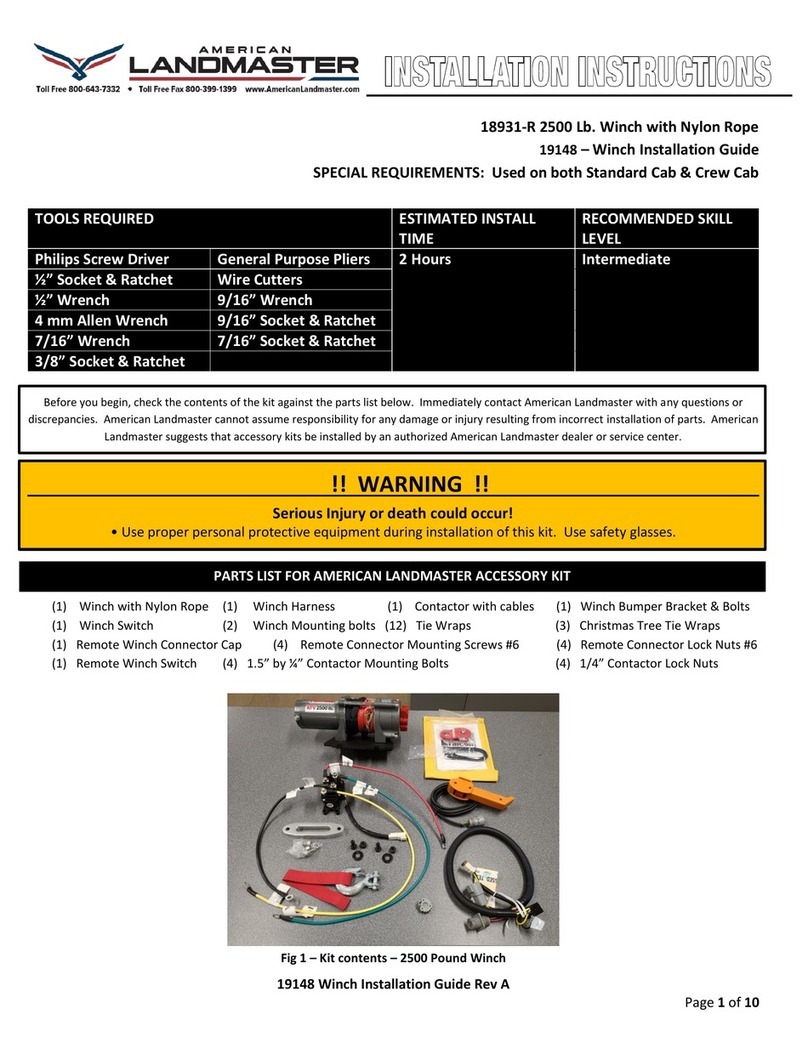

Fig. 7

Fig. 9

• Briefly operate the controller that is being used (stationary or handheld) to ensure that

the winch works properly.

• IN - button should retract the winch cable

• OUT - button should extend the winch cable

• If operation is reversed, the power connections to the winch may be connected

backwards. Correct the wiring before continuing with operation.

• Standing aside the vehicle, retract the winch cable and winch the item as desired.

Winch cable may slip or break causing serious injury

or death

WARNING

Do not retract the hook all the way back into the winch

roller guides as this will damage the roller and could

lodge the hook in the winch

CAUTION

Overwinding the winch cable into the roller guides can

jam the winch causing it to not release with the

twist knob.

CAUTION

Constant duty loading of the winch will overheat the

winch motor and may cause damage to both the winch

and the battery.

CAUTION

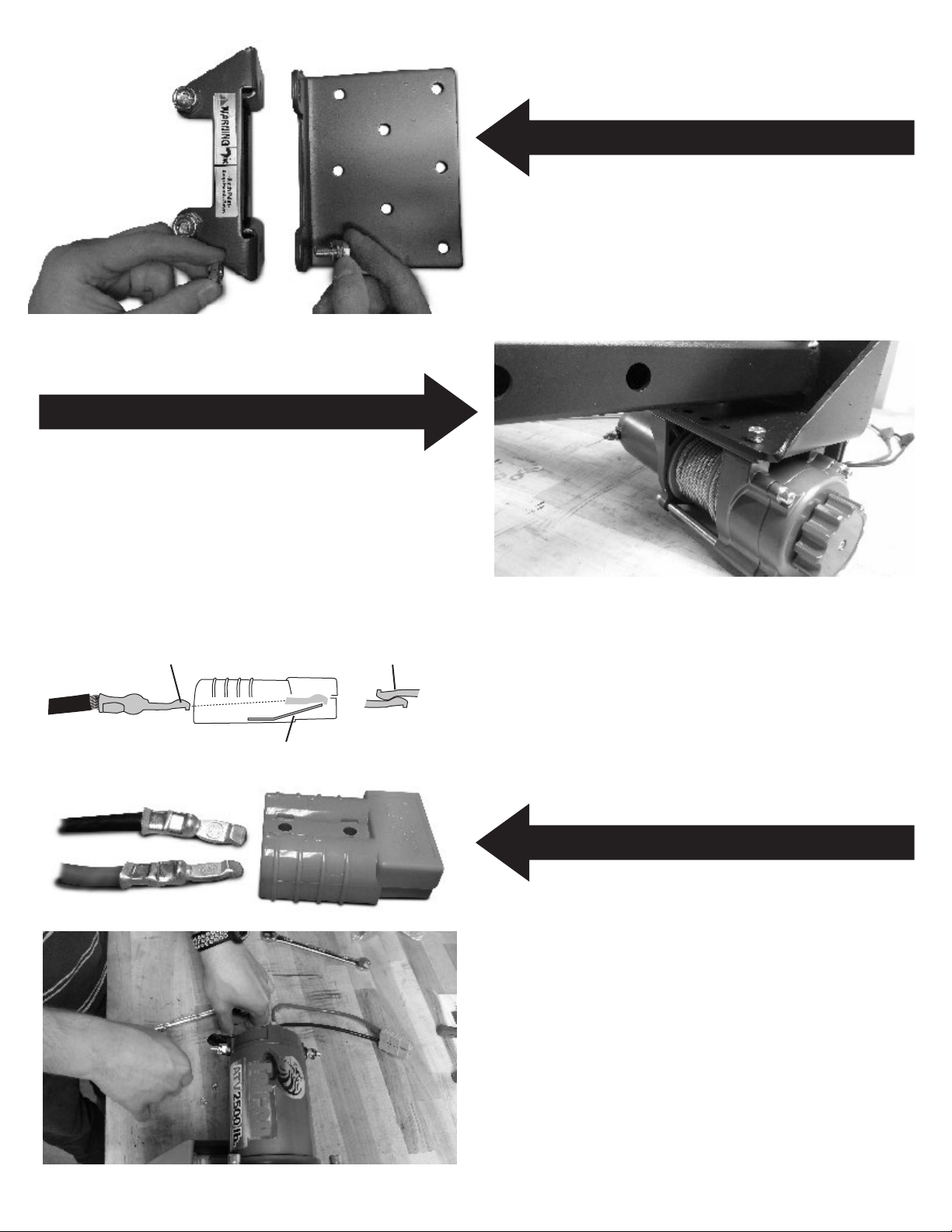

Fig. 8

Additional Winch Information

• When finished pulling the load, secure the load and add slack to the wire cable by

reversing the direction which will release tension and allow easy disconnection from

the hook.

• Duty Cycle: 5% - This winch is designed for intermittent use. The duty cycle is the

amount of time the winch can operate at its maximum capacity for a 15 minute period

of time.

• 45 Seconds at max rated load

• 14 minute rest between winching at rated load

• Double line rigging can be utilized to reduce the winch load. An appropriate pulley

block is included for this technique.

• Wear ANSI approved safety gear including gloves, goggles and shoes.

• Entanglement may occur. Do not wear loose clothing or jewelry, as they may get

caught in moving parts. Restrain long hair.

• Do not lift items vertically.

• Do not use to lift or move people.

• Do not use vehicle to pull on the winch cable and assist the winch.

• Disconnect battery cables before working on or near the winch cable, drum, roller

guides, or wire connections to prevent accidental starting.

• Inspect the winch before each use. Cracks, bent parts, frayed or kinked winch cable

will weaken the integrity of the winch and may cause sudden failure. A winch with

damaged components or questionable winch cable must not be used.

• Do not exceed the rated load capacity of the winch.

• Be aware of dynamic loading! Sudden load movement may briefly create excess load

causing product failure.

• Do not release the clutch under load.

• Do not place fingers through the hook. Fingers may get caught and entangled in

winch roller guide. Use supplied strap to hold hook.

• Stay clear of the winch cable when under load. Standing in the direct line of the

winch cable or behind the winch while operating may cause serious injury or death if

the winch cable were to break or slip.

• Do not use a recovery strap to winch. Recovery straps are designed to stretch and

may suddenly break and spring back towards the operator.

• Secure the load after moving. This winch is not equipped with a locking

mechanism.

• Keep at least 5 full turns of winch cable on the drum. Connection to the drum is not

intended to sustain a full load.

• People with pacemakers should consult their doctor or physician before use.

Electromagnetic fields in close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

WARNING THE FOLLOWING MAY CAUSE SERIOUS INJURY OR DEATH!

Contact American LandMaster Customer Service for questions

or problems that may arise with the assembly and starting of

this unit at 800-643-7332 or at americanlandmaster.com.

Fig. 6

Check your vehicle:

• Examine the winch cable. Do not use the winch if the cable is frayed, kinked or

damaged.

• Check the Winch electrical connections to ensure that they are tight and clean.

• Put the vehicle transmission in NEUTRAL and apply the parking brake.

Prepare the Winch:

• IF the vehicle with the winch is to

remain in place during the winch

operation, engage the parking brake and

chock the wheels (chocks sold

separately).

• Use the hook strap to pull out the

wire cable by moving the Clutch Control

Knob to the “OFF” (Free Spool) position

as shown in see figure 6.

Leave at least 5 full turns of wire cable on the drum.

WARNING

Do not wrap the winch cable around the object and hook

onto the cable itself. This will damage the winch

cable and object being pulled (see figure 7).

CAUTION

Basic Operation

FREE SPOOL

ENGAGE

“OFF” position

“ON” position

Attach Winch to the Object:

• Attach to the object by using a pulling point, tow strap or chain.

• Attachment point must be centered in the loop of hook and the safety clasp must be

fully closed (see figure 8).

• DO NOT use a recovery strap while winching. They are designed to stretch and

can suddenly whip back towards the operator during a winching operation.

• Place a rug or carpet over the winch cable span (approx. 6’ from the hook) to help

absorb the force released if the cable breaks (see figure 9).

• Move the Clutch Control Knob to the “Engaged” position and use either the stationary or

handheld controller to operate the winch.

15961 Rev. C

page 7 of 7