4.3 TEMPERATURE

A battery location having an ambient temperature of 25°C

(77°F) will result in optimum battery life. Batteries operated

above this temperature will suffer reduced life, while batteries

operated below this temperature may exhibit suppressed

capacity. Though brief temperature excursions between

0°C (32°F) and 40°C (104°F) can be tolerated, the normal

operating temperature is between 16°C (60°F) and 32°C

(90°F).

4.4 ELECTROLYTE LEVEL

During normal operation, the electrolyte level should be

between the high and low marks on the battery container.

Upon receipt of the battery, the electrolyte level may be a

bit lower than this mark; after charging, it may be higher.

The reason is that gas bubbles formed during charge will

adhere to the battery plates, displacing and raising the

electrolyte level. Do not attempt to adjust the electrolyte

either immediately upon receipt or immediately after the

initial charge.

4.5 CELL POSITIONING

By now, it is assumed that the rack has been assembled.

Determine the desired position of the positive and negative

terminals. Measure and mark the center of the rack.

Determine the number of battery blocks that will fit on a step/

tier of the rack. If that number is odd, position the centerline

of the first battery block on the centerline of the rack step/tier.

If the number is even, position the end of battery block on

the centerline of the rack step/tier. Work from the center out,

positioning the positive terminal next to the negative terminal

of the adjacent cell.

If a lubricant is needed to facilitate battery

positioning, use only Dow Corning 111.

Lubricants that contain solvents may damage

the battery containers and void warranty.

4.6 FLASH ARRESTORS

After the batteries have been positioned on the rack (but

before the inter-unit and inter-tier connections have been

made), replace the shipping caps with the provided flame/

flash arrestors.

4.7 CONTACT SURFACES

Gently clean the contact surfaces of the battery terminal

posts using a 3M Scotch Brite or similar scouring pad. Coat

the electrical contact surfaces lightly with provided No-Ox

grease.

4.8 ELECTRICAL CONNECTIONS

Install and torque the provided M8 stainless steel hardware

and torque the cell connector (or terminal plate) to the post.

Target connection torque is 100 - 110 inch-lbs. (11.3-12.0

N-m). Re-torque the stainless steel hardware 24 hours after

the initial tightening to account for relaxation of the lead-

hardware connection.

Electrical connections must be clean to minimize voltage drop

and prevent connector heating. If corrosion is observed, DO

NOT RE-TORQUE! The connection must be disassembled,

cleaned, neutralized, and then re-torqued.

Install the inter-tier cables as necessary. Do not connect

cables directly to the battery post. Utilize the terminal

plates provided for main terminal and inter-tier connections.

Re-check to be certain that the batteries are connected

positive terminal to negative terminal throughout the string.

Before connecting the battery string to the charger/load,

measure the total voltage at the battery terminals. The

voltage should be equal to the number of cells times the

voltage of one cell. For example, 60 cells times 2.09 volts

per cell = 125.40 volts (1.250 SG) or 60 cells times 2.05 volts

per cell = 123.0 volts (1.215 SG).

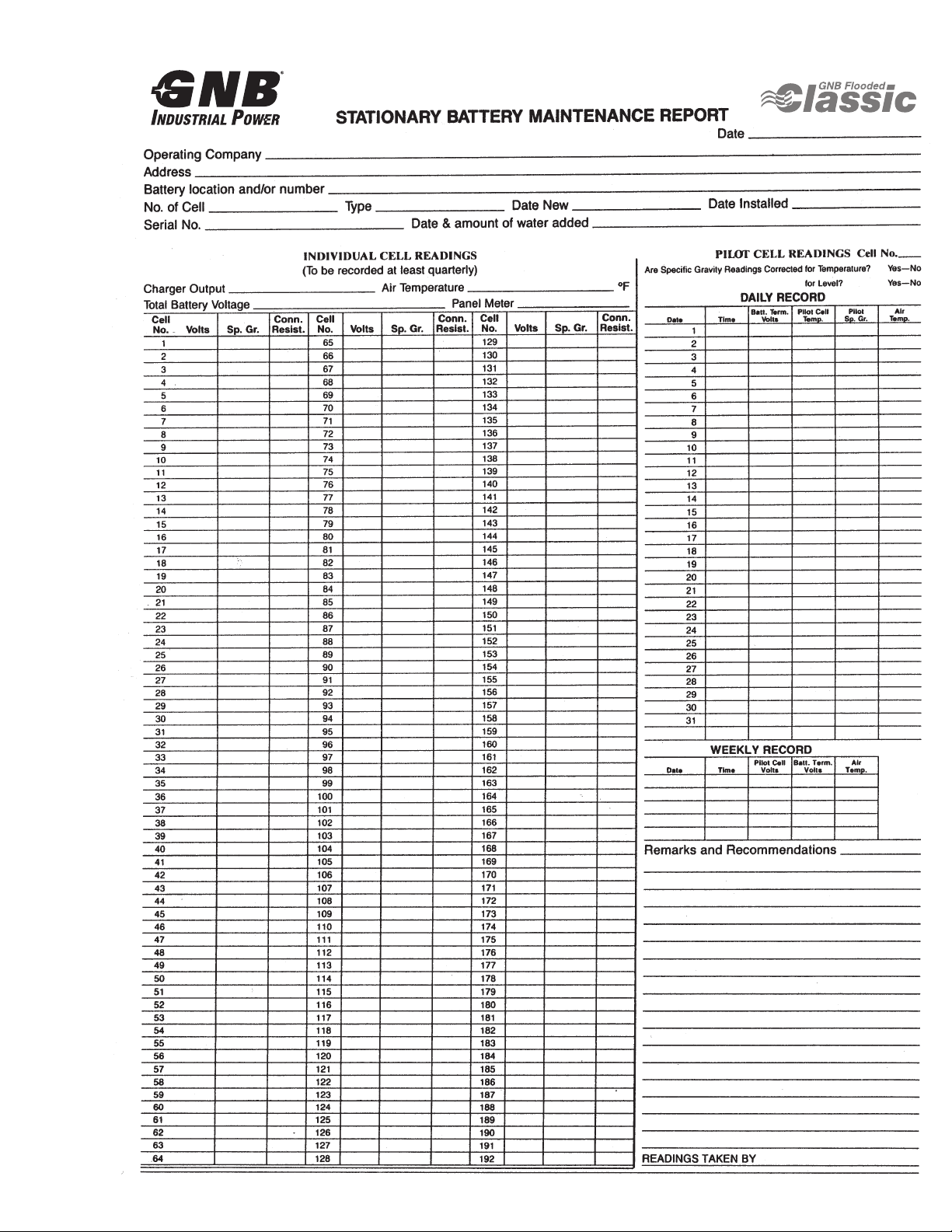

4.9 CONNECTION RESISTANCE

Connection resistance or micro-ohm (µΩ) measurements

should be taken at the time of installation and annually

thereafter. Initial measurements at installation become

benchmark values. Future values are compared to

this benchmark as an indication of connection integrity.

Re-torque of connections should be performed annually or

when connection resistance increases to more than 20%

over the benchmark value.

4.10 Labels and Markings

Numerals and polarity markings should not be applied

until after the cells have been installed on the rack. It is

recommended that they be applied to jar surfaces only, and

not to cell covers or rack rails.

2. Clean the plastic jar surface, in the area where the

numeral is to be located, by using a cloth dampened with a

washing soda solution. Immediately dry the area using a soft

dry cloth to remove residual washing soda.

CAUTION!! Do not use any solvent type materials as they

may cause damage to the plastic jar material.

3. It is a general practice to designate the positive terminal

cell as #1 with succeeding cells in series in ascending order.

4.11 INITIAL CHARGE

The first charge that the battery receives after shipping,

storage and installation is very important as it may affect the

life of the battery. Determine the maximum charge voltage

output that the charge system can provide and charge the

battery in the least amount of time possible according to

Table A. This maximum voltage divided by the number of

cells connected in series is the maximum charge voltage per

cell (VPC). If long periods of continuous charging are not

possible at the installation, (e.g. photovoltaic applications)

the battery should be charged where such capability exists.

The recommended times given in TABLE A are considered

minimum. Charge the cells until the charge current tapers

and stabilizes for 3 hours. Then, charge the battery for the

times and voltages given in TABLE A.

3