CONTENTS

WHAT IS THE GOFERMENTOR? .....................................................................................................................................4

GOFERMENTOR JR.........................................................................................................................................................4

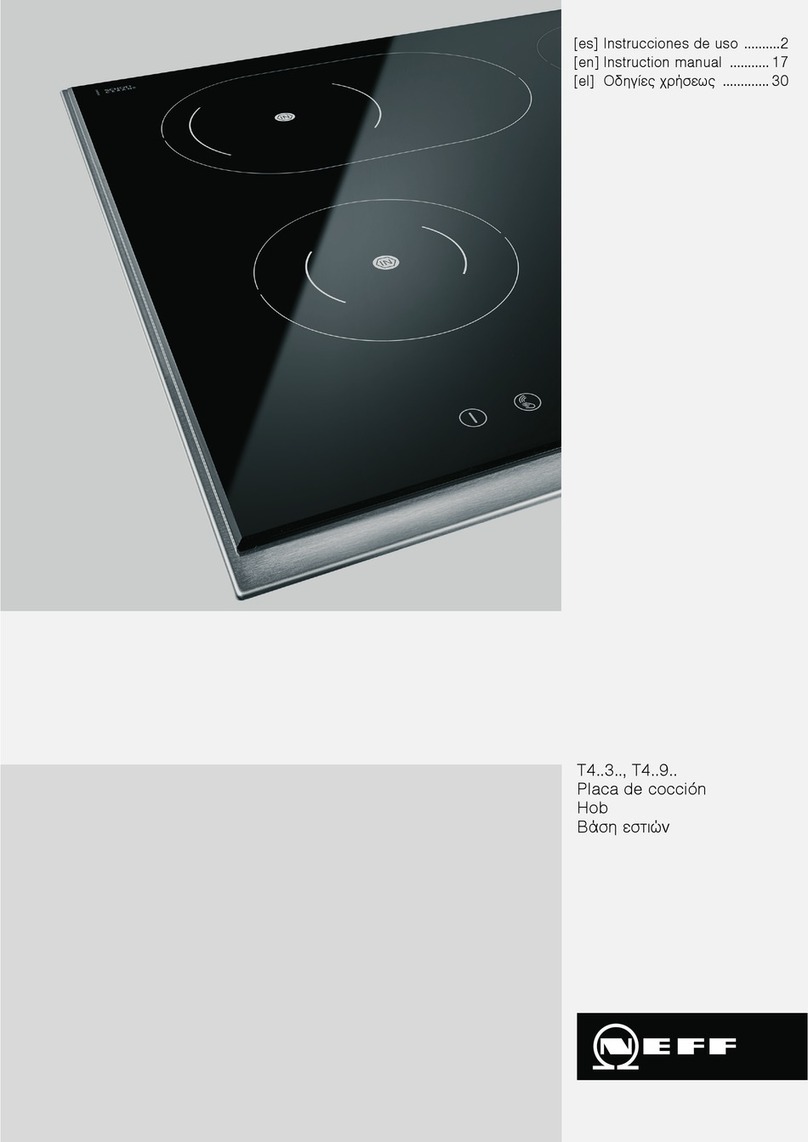

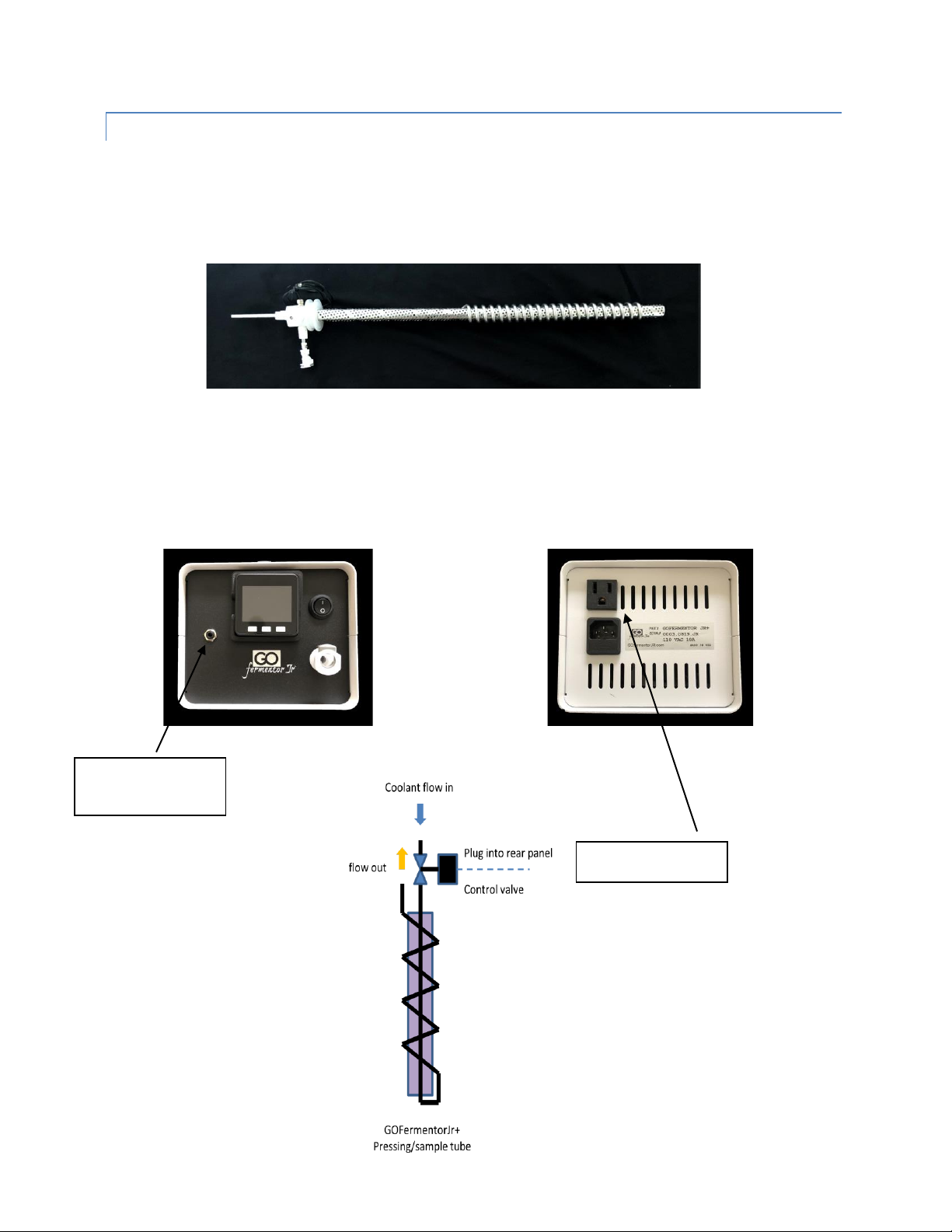

COMPONENTS ...........................................................................................................................................................4

OPTIONAL ..................................................................................................................................................................4

DISPOSABLES .............................................................................................................................................................4

YOU WILL NEED TO PROVIDE.....................................................................................................................................4

INITIAL EQUIPMENT SETUP .......................................................................................................................................5

RED WINE FERMENTATION .........................................................................................................................................12

PUNCHING ...............................................................................................................................................................12

SAMPLING................................................................................................................................................................15

PRESSING out the wine............................................................................................................................................16

DEFLATION...............................................................................................................................................................20

AGING AND RACKING ..............................................................................................................................................21

WHITE WINE FERMENTATION .....................................................................................................................................22

PREPARATION..........................................................................................................................................................22

PRESSING out the juice............................................................................................................................................22

FERMENTATION.......................................................................................................................................................24

APPENDIX 1 operating the controls.............................................................................................................................25

APPENDIX 2 Controller configuration..........................................................................................................................37

APPENDIX 3 SPECIFICATIONS.......................................................................................................................................40

APPENDIX 4 SOURCES..................................................................................................................................................42

APPENDIX 5 troubleshooting and faq..........................................................................................................................44

APPENDIX 6 Warranty, support, Liability, and Returns Policy.....................................................................................49

APPENDIX 7 terms and conditions of sale ...................................................................................................................50