Copyright © 2018 Graphics One

Chapter 1 Preface

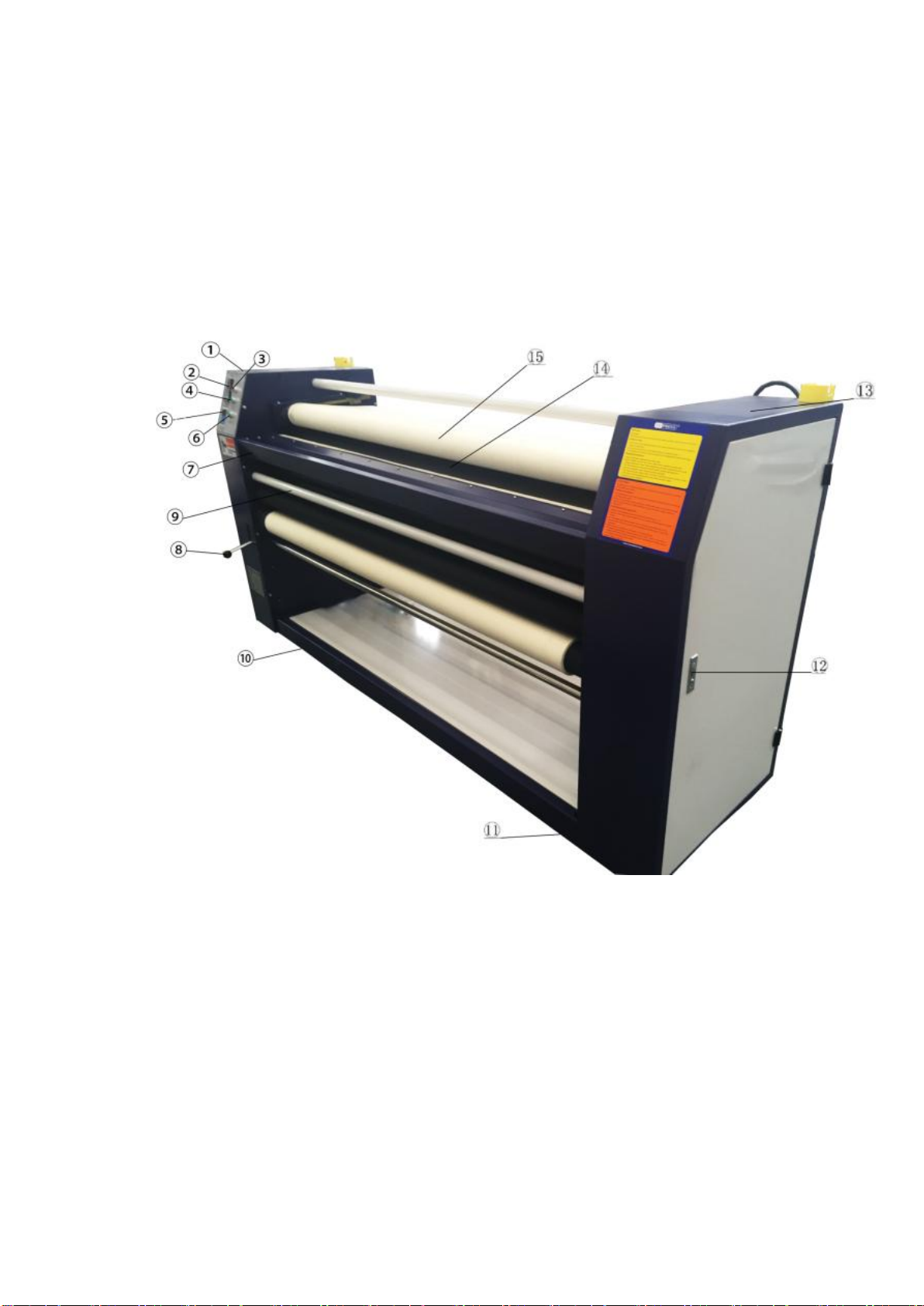

X-Press 68 is a type of rotary digital presses. It is adopted electric heating

diversion around oil layer, fast temperature rising, stable temperature on cylinder

surface, four shafts interlock, blanket disengaging mechanical structure. It is applied

for garment sheets, fabric rolls, flags, socks, blanket and curtain, ect.

1.1 Attention

A This manual offers installation, debugging, parameter set, trouble-shooting,

operation and attention. Please take care of this manual.

B Read this manual carefully before installation and debugging to avoid damage

and accident for mistake.

C User must select matched lead for power supply according to rating power of this

machine and install specially used leakage circuit breaker

D The outer of this machine must be earthing, or else, it will damage to human

beings.

E This machine must be equipped in ventilated, lightful environment at the vertical

direction .At least; there is1.5m space is around the machine.

F Immediately stop running to check the machine if abnormal situation occurs. At

the same time, the blanket should be out of cylinder, flow fan is helpful for cooling to

avoid damage of blanket.

G Operator must obey forbidden sign of all parts in this machine to operate.

HAs the equipment is heating machinery, there may be certain noises from the roller,

heating body or big/small bearings during the operation process, which is the normal

phenomenon and you may not worry about it;

I The control circuit plate and the transducer inside the machine case shall be kept

clean regularly with no dust or any other metal products fallen inside. Please do not

open the protection cover to avoid electric shock;

J The heating body, speed reducer and heat transfer oil etc of our company shall be

used for any replacement and please do not replace or rectify the equipment without

our permission.

K The external surfaces of heating tube are specially treated and do not use the