CONTENT

CONTENT........................................................................................Hata! Yer işareti tanımlanmamış.

LIST OF FIGURES..........................................................................Hata! Yer işareti tanımlanmamış.

MAIN SAFETY INFORMATION...................................................Hata! Yer işareti tanımlanmamış.

STICKERS USED ON THE MACHINE.........................................Hata! Yer işareti tanımlanmamış.

INTRODUCTION ............................................................................Hata! Yer işareti tanımlanmamış.

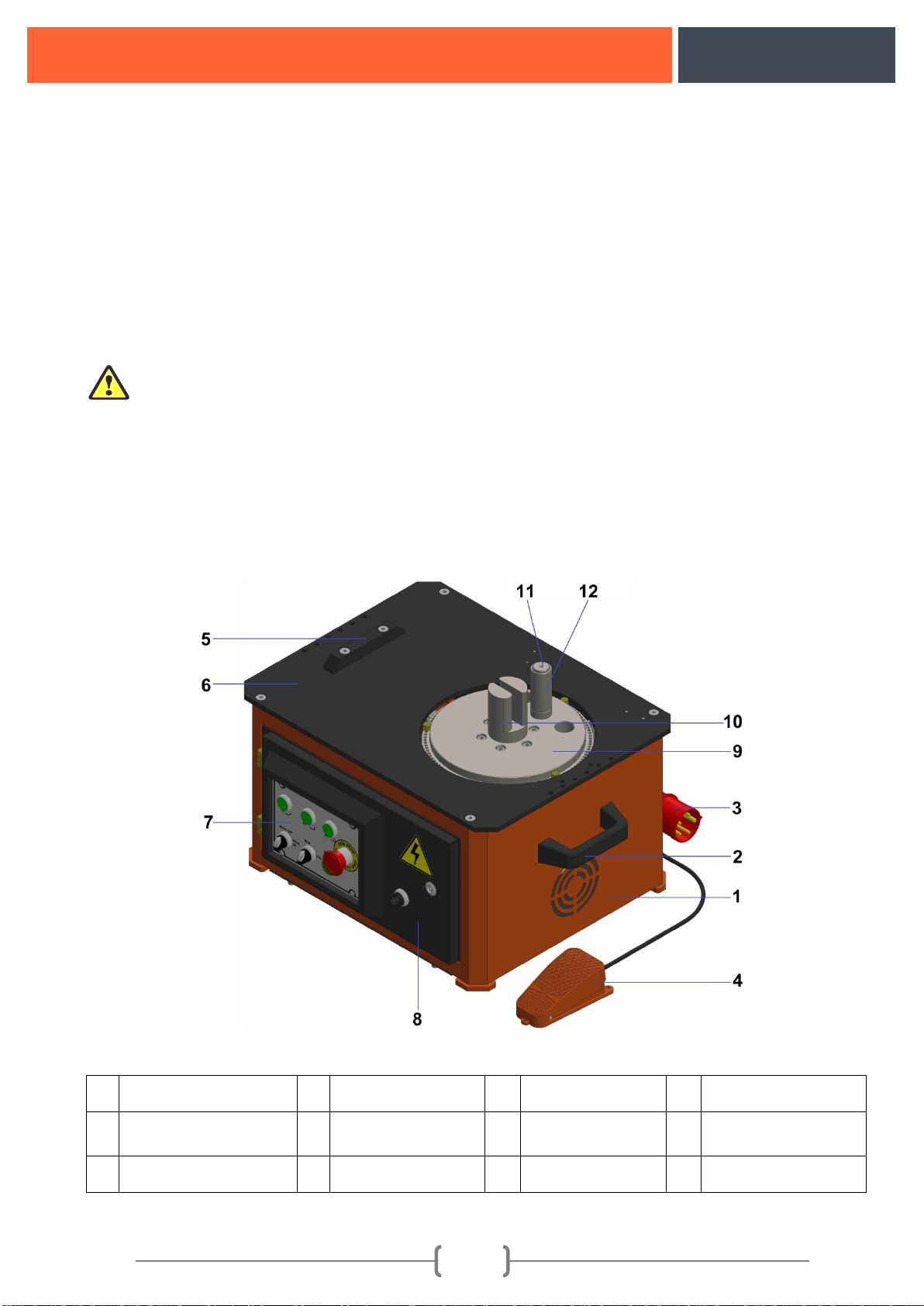

1. MAIN SECTIONS OF REBAR BENDING MACHINE.....................................................................4

2. MACHINE ASSEMBLY......................................................................................................................5

3. MACHINE RUNNING PROCEDURES ORDER...............................................................................6

3.1. Energise and Rotation Determining the Direction of Rotation..............................................................6

3.2. 380V Manual Machine Operation ......................................................................................................7

3.3. 220V Manual Machine Operation ......................................................................................................8

3.4. 380V Digital Machine Operation ........................................................................................................9

3.5. 220VDigital Machine Operation.......................................................................................................10

4. TECHNICAL DATA..........................................................................................................................11

5. EQUIPMENT SUPPLIED WITH MACHINE...................................................................................11

6. OPERATION OF MACHINE............................................................................................................12

6.1. Correct Positioning of Rebar On The Machine............................................................................12

6.2. Incorrect Positioning of Rebar On The Machine .........................................................................12

7. PROHIBITED USAGE ON THE MACHINE ...................................................................................13

8. SCOPE OF WARRANTY..................................................................................................................13

9. PROTECTORS TO BE USED WHEN WORKING WITH THE MACHINE..................................14

9.1. Protector apparel...........................................................................................................................14

9.2. Work clothes.................................................................................................................................14

10. TRANSPORTATION THE MACHINE ..........................................................................................14

11. CONTROLS AND SETTINGS ON THE MACHINE.....................................................................15

11.1. Thermal Settings Diagram And Motor Protective Switch ........................................................16

11.2. Hook Bending setting (P3-45°) .........................................................................................……17

11.3. Set-Square Bending setting (P2-90°): .......................................................................................18

11.4. Bent Bar Bending setting (P1-180°): ........................................................................................18

11.5. Stirrup Bending .........................................................................................................................19

12. MAINTENANCE AND LUBRICATION INSTRUCTIONS..........................................................19

13. TROUBLESHOOTING....................................................................................................................20

14. MACHINE SPARE PARTS LIST....................................................................................................21