©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the

right to amend specifications without notice or obligation.

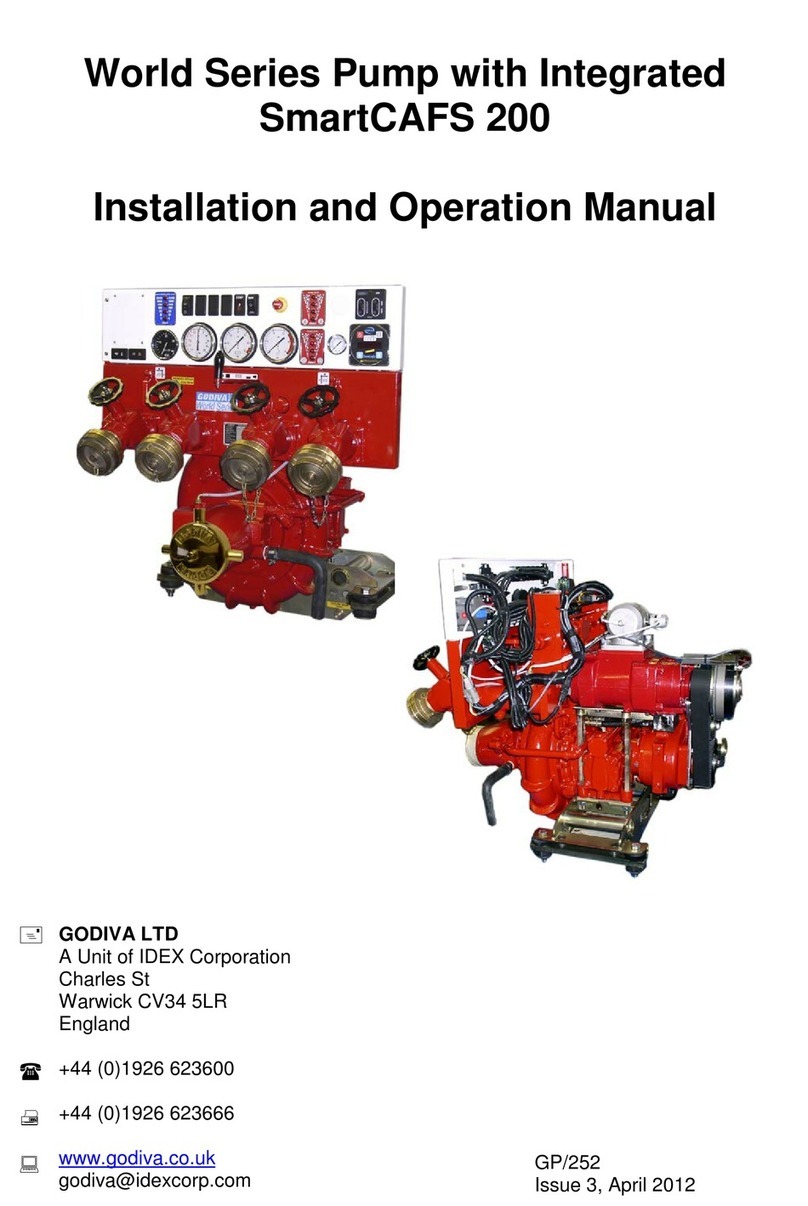

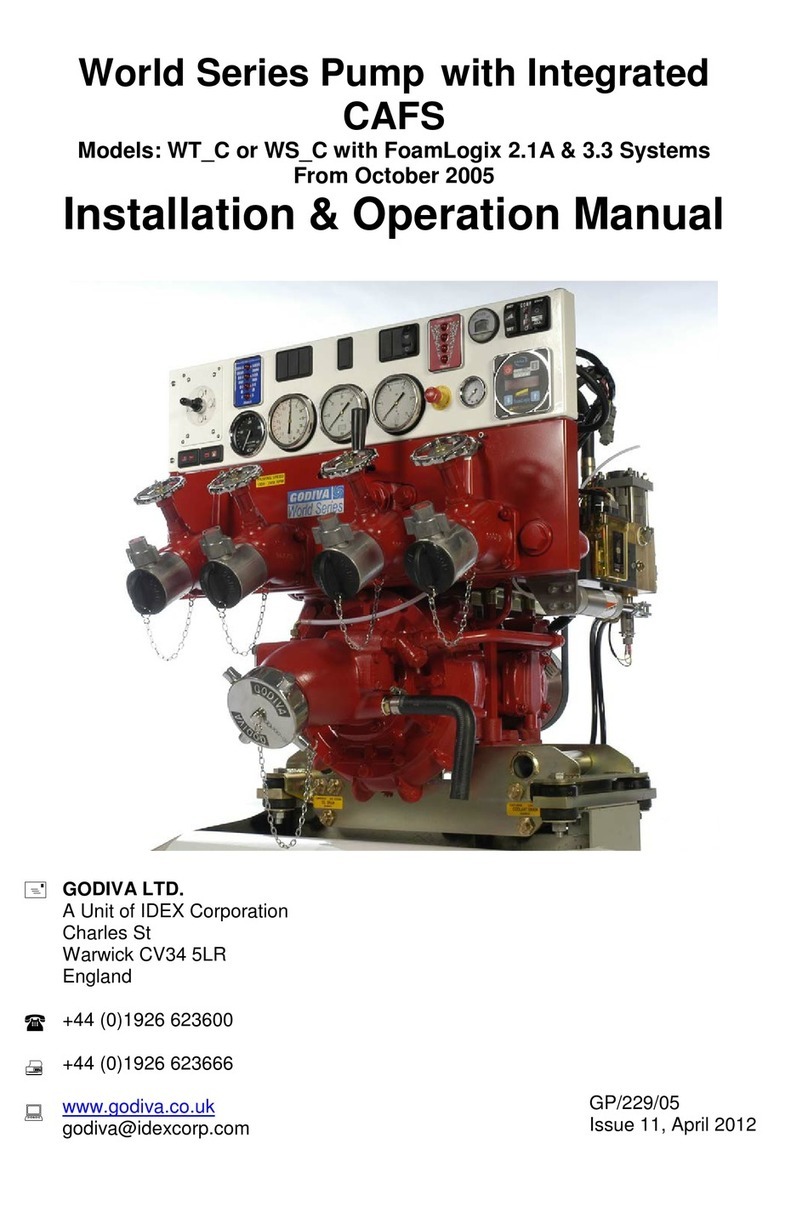

INSTALLATION AND INITIAL SET-UP PRIMA SMARTCAFS50 USING TEMPEST 3

COMPRESSOR AND FOAMLOGIX 2.1A PRIMASMARTCAFS100 USING TEMPEST

6 COMPRESSOR AND FOAMLOGIX 3.3 OR 5.0........................................................20

LIFTING POINTS –PRIMA SMARTCAFS50 AND PRIMA SMARTCAFS100 ..........................20

PRIMA SMARTCAFS50 SYSTEM....................................................................................21

FOAMLOGIX 2.1A SYSTEM –REMOTE MOUNTED ............................................................21

PRIMA SMARTCAFS100 SYSTEM..................................................................................22

FOAMLOGIX 3.3 OR 5.0 SYSTEM –REMOTE MOUNTED (3.3 MODEL SHOWN).....................22

OIL FILLING POINTS –PRIMA SMARTCAF50...................................................................24

OIL FILLING POINTS –PRIMA SMARTCAF100.................................................................25

GEARBOX –PRIMA SMARTCAFS50 AND PRIMA SMARTCAF100 .....................................26

GEARBOX IN DOWN POSITION........................................................................................26

GEARBOX IN HORIZONTAL POSITION,LEFT OR RIGHT OF PUMP ........................................26

FOAM INJECTION POINT ................................................................................................27

OPTICAL BELT TENSION METER.....................................................................................28

COMPRESSOR DRIVE BELT –PRIMA SMARTCAFS100....................................................29

OPTICAL BELT TENSION METER.....................................................................................29

ELECTRICAL CONNECTIONS...........................................................................................29

FOAM TANK LOW LEVEL SENSOR...................................................................................31

ADDITIONAL INSTALLATION POINTS ................................................................................31

VEHICLE DESIGN CONSIDERATIONS.......................................................................32

INSTALLATION AND INITIAL SET-UP FOAMLOGIX 2.1A.........................................33

INSTALLATION AND INITIAL SET-UP FOAMLOGIX 3.3, 5.0 ....................................33

OPERATION.................................................................................................................34

FOAMLOGIX CONTROL PANEL FUNCTIONS......................................................................34

COMMISSIONING /START-UP PROCEDURE .....................................................................34

CALIBRATION OF FOAMLOGIX ........................................................................................35

SMART SWITCH OPERATION...........................................................................................35

WET AND DRY BUTTONS..............................................................................................36

WET AND DRY LEDS..................................................................................................36

CONFIGURE THE WET AND DRY PRESETS .....................................................................36

CONFIGURE THE WET PRESET......................................................................................36

CONFIGURE THE DRY PRESET ......................................................................................36

OPEN AND CLOSE BUTTONS.......................................................................................36

OPEN AND CLOSE LEDS...........................................................................................37

VALVE POSITION BARGRAPH INDICATOR (LEDS)..............................................................37

NOTE:TURNING OFF THE FOAMLOGIX OR DISENGAGING THE COMPRESSOR WILL SEND THE

AIR RATIO CONTROL VALVE TO THE EXTREME WET POSITION..........................................37

OPERATING THE PC2_ OR PC1_ FROM A VEHICLE WATER SOURCE................................37

FOAMLOGIX CONTROL PANEL .......................................................................................38

ENGAGING PTO &PRIMING MAIN PUMP ........................................................................38

TANK SELECTION FOAMLOGIX 3.3, 5.0 ONLY..................................................................38

DISCHARGING FOAM /WATER SOLUTION ONLY...............................................................39

DISCHARGING CAFS....................................................................................................39

OVERHEAT SHUT DOWN................................................................................................40

FLUSHING FOAMLOGIX 3.3 OR 5.0 ONLY.........................................................................40

MAINTENANCE SCHEDULE PC2_/PC1_....................................................................41