2005

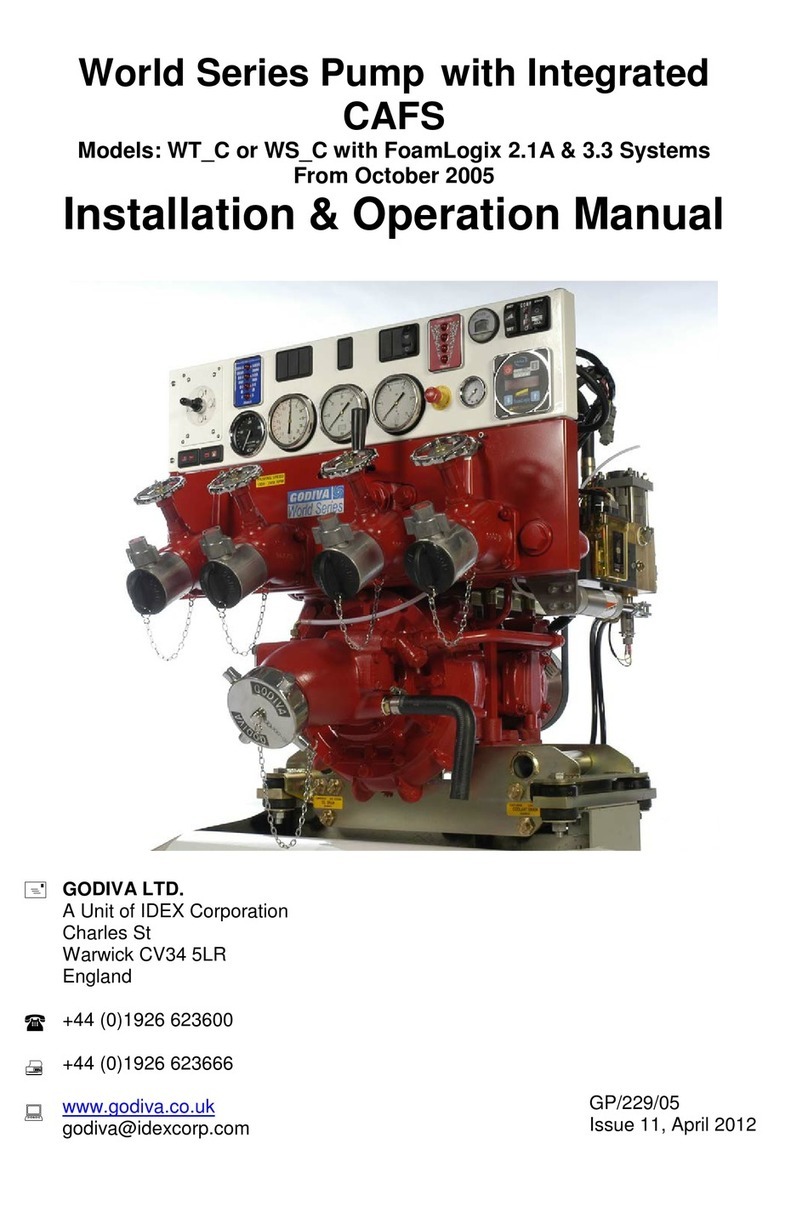

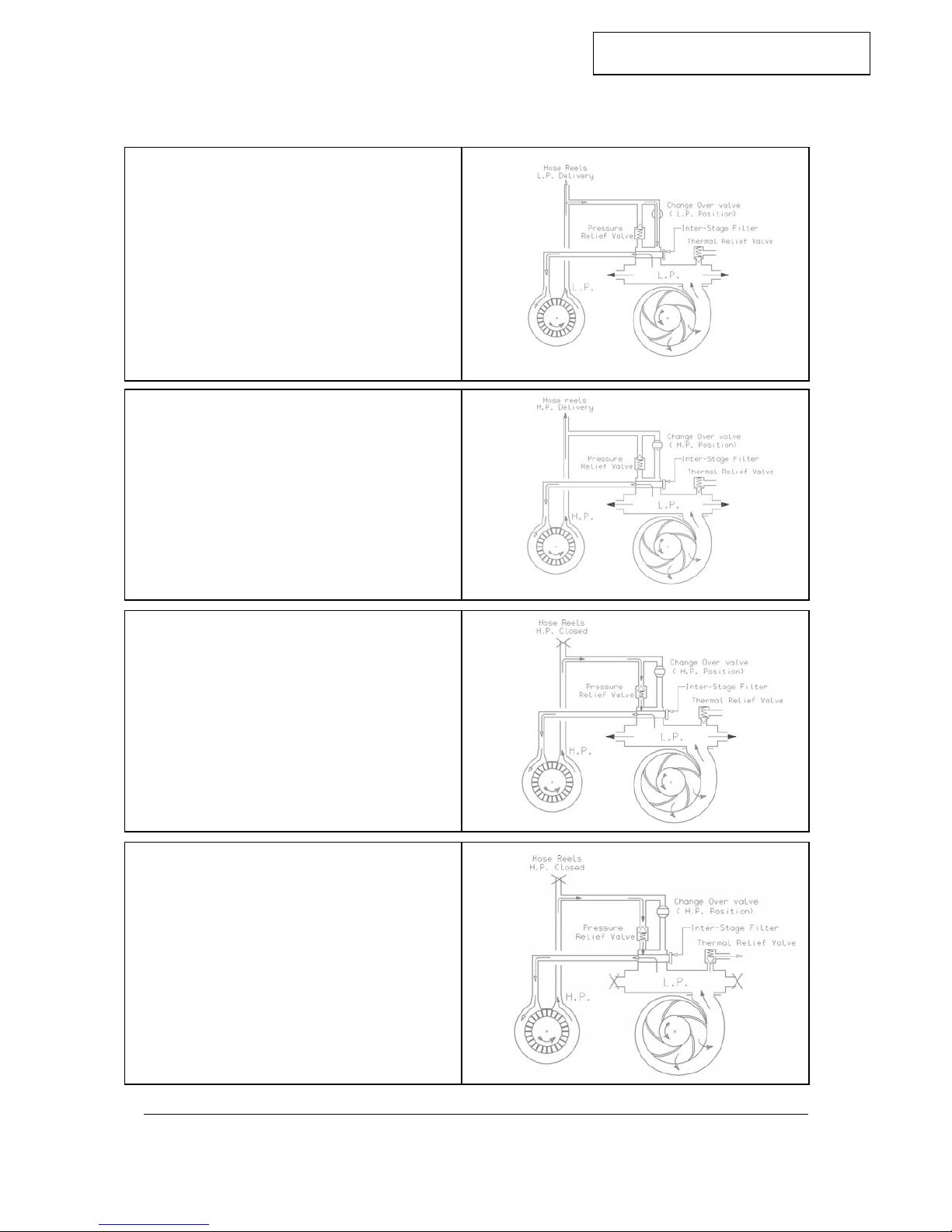

The Godiva WT Series two-stage pump is a dual pressure pump. It can be used for

high volume, low pressure (LP) output or for low volume, high pressure (HP) output,

or both simultaneously. When the pump is running, LP flow is always available, but

HP is available only if the HP selector valve is in the closed position. The HP outlet

is separate from the LP outlets and is mounted on the top rear of the pump. It is

recommended that if HP is not required, then the change over valve is left in the

open position, as this will reduce engine and transmission loads and noise.

A pressure relief valve is fitted which allows a small amount of water to circulate

back to the LP stage to prevent the pump from developing excessive pressure,

should it be operated at HP against closed HP discharge valves.

The pump is generally driven in a clockwise direction viewed from the drive end. The

pump may also be specified configured to rotate in a counter-clockwise direction.

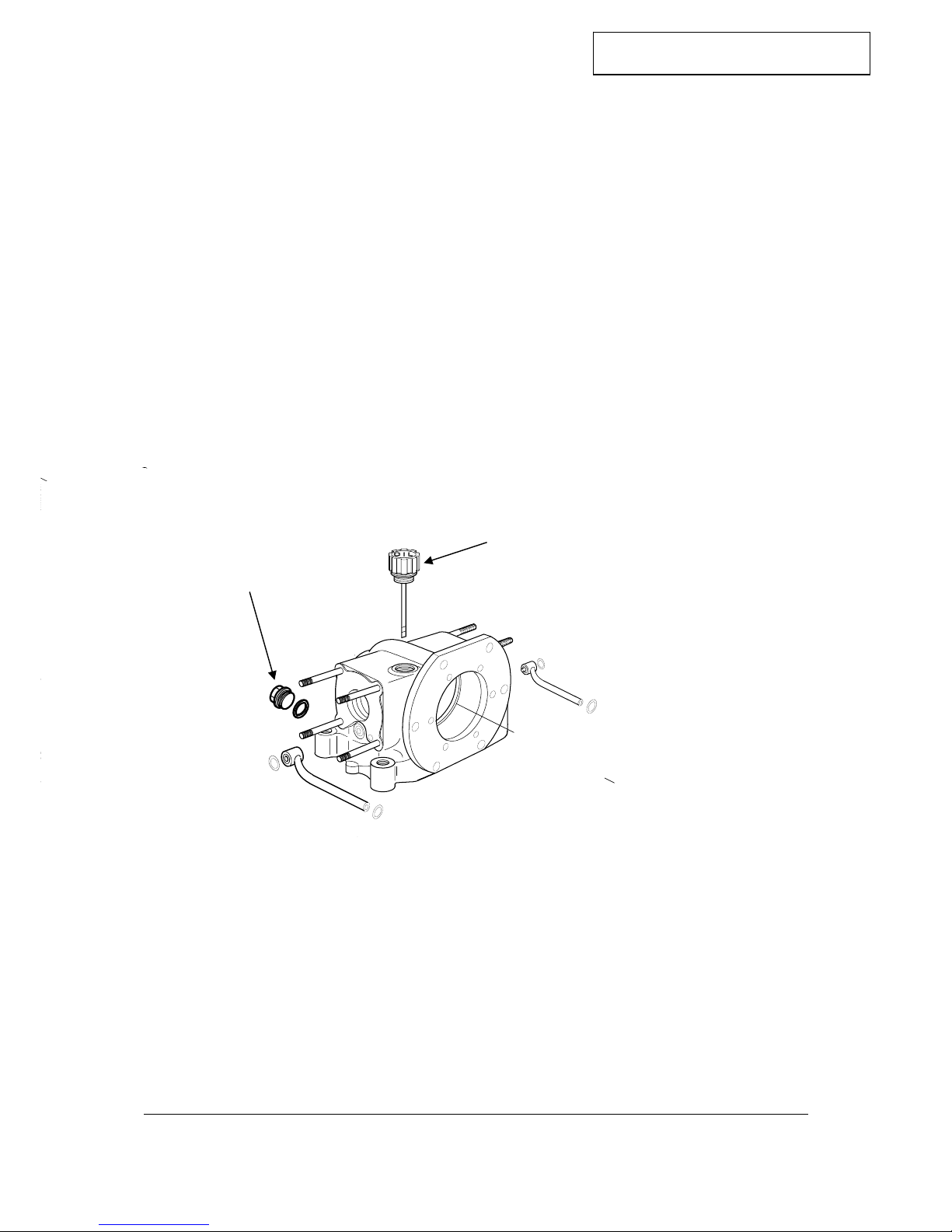

The pump drive shaft, which runs on angular contact and roller bearings in an oil

bath, is of stainless steel. Shaft sealing of the pump is by a special Godiva

mechanical seal face, which ensures efficiency and long life without adjustment. The

electronic tachometer sender is mounted adjacent to the drive flange.

Priming of the pump is achieved automatically by means of a pair of positive

displacement piston primers mounted on either side of the bearing housing. These

primers begin to operate as soon as the pump drive shaft begins to rotate, driven by

an eccentric bearing on the pump shaft. Air within the pump will be expelled and as

long as the suction connections have been made and the hose end submerged, the

pump will prime and the pistons will disengage by 1.5 bar. The pump should be

primed at any speed between 1000-2500 rpm. The pump speed should not be

increased further until the primers have disengaged and the pump is primed.

An optional alternative priming system – the Godiva water ring primer – is available

in place of the piston primer system. With the water ring primer, when the pump is

started, the primer shaft is driven by its fibre driving wheel which contacts the pulley

on the pump drive shaft and is lifted off by a disengaging cylinder as the pump is

primed and pressure builds up in the pump. An alternative to friction pulley drive is

belt-drive through an electro-magnetic clutch. When the pump is primed and

pressure builds up, a pressure switch turns off the clutch drive.

Non-return valves are built into both the piston and water ring priming systems to

prevent air flowing back through the primers, thus “breaking the prime”.

As the pump is reduced to idling and the pressure within the pump decreases, the

pistons will once again reengage to act as a pump and discharge any water

remaining in the pump.

HP delivery is from a connection mounted on the top rear side of the pump which is

threaded internally to 1 ¼" BSP or rearwards via a flange.

A World Series Options Manual is available which shows many of the standard

specifications currently available together with an indication of their positions relative

to datum points on the pump.

©Hale Products Europe LTD, Warwick

GP/146/99

WTmaint - Issue9. 10-2005October 2005

8