©Godiva Ltd. Our policy is one of continuous development. We therefore reserve the

right to amend specifications without notice or obligation.

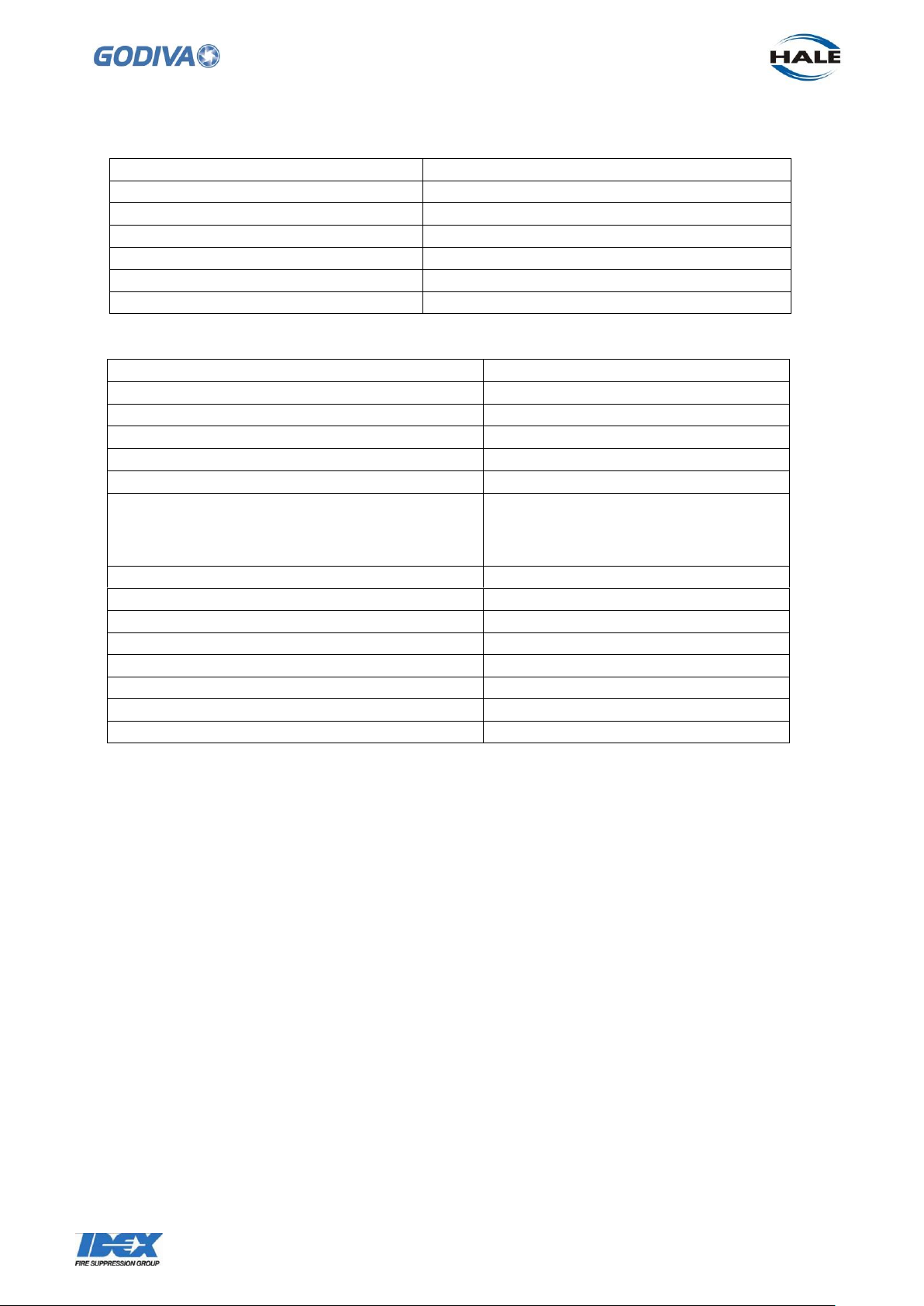

CONTENTS

AMENDMENT RECORD...............................................................................................1

CONTENTS...................................................................................................................2

IMPORTANT NOTES ....................................................................................................5

SAFETY RELEVANT DATA..........................................................................................6

MAINTENANCE.........................................................................................................................6

TRAINING ................................................................................................................................6

SAFETY POINTS.......................................................................................................................6

ENVIRONMENTAL PROTECTION ...............................................................................7

GENERAL DATA ..........................................................................................................8

ENGINE...................................................................................................................................8

WEIGHT &MATERIALS..............................................................................................................8

CONSTRUCTION MATERIALS .....................................................................................................9

PUMP......................................................................................................................................9

RECOMMENDED OPERATING PRESSURE .................................................................................10

OPTIONAL EQUIPMENT ...........................................................................................................10

AUXILIARY SOCKET................................................................................................................10

ASSOCIATED PUBLICATIONS ...................................................................................................10

MAJOR COMPONENTS AND CONTROLS 17/10 AND 12/10 MODELS...................11

GENERAL ARRANGEMENT -LEFT HAND VIEW (FROM FRONT)....................................................11

GENERAL ARRANGEMENT -RIGHT HAND SIDE (FROM REAR).....................................................12

GENERAL ARRANGEMENT –CONTROLS AND INSTRUMENTS......................................................13

ENGINE FLUIDS.........................................................................................................14

MAINTENANCE SCHEDULE......................................................................................16

MAINTENANCE OPERATIONS..................................................................................17

Flush Pump....................................................................................................................................... 17

Frost.................................................................................................................................................. 17

Engine Coolant Level........................................................................................................................ 17

Coolant Change................................................................................................................................ 18

Engine oil fill and level Check........................................................................................................... 19

Change Engine Oil and Filter............................................................................................................ 20

Engine Fuel Filter.............................................................................................................................. 21

Air Filter Element .............................................................................................................................. 21

Check and Adjust Valve play............................................................................................................ 21

Sparking Plugs.................................................................................................................................. 22

Preparing the unit for storage ........................................................................................................... 22

PUMP TESTS .........................................................................................................................23

Running Test..................................................................................................................................... 23

Vacuum Test - Exhaust Gas Priming................................................................................................ 23

Pressure Test.................................................................................................................................... 23

BATTERY CARE......................................................................................................................23

Safety................................................................................................................................................ 23

Terminals .......................................................................................................................................... 24

Charging............................................................................................................................................ 24

Gauges.............................................................................................................................................. 24

FAULT TRACING........................................................................................................24