CONTENTS

SPECIFICATIONS ........................................................................................................................ 1

IMPORTANTSAFETYINFORMATION ..................................................................................... 3

COMPONENT&CONTROLLOCATIONS ................................................................................ 4

BEFOREOPERATION ................................................................................................................ 5

GeneralConditionoftheEngine ...................................................................................... 5

ChecktheEngine............................................................................................................... 5

EquipmentPoweredbyEngine.......................................................................................... 5

SafeOperatingPrecautions............................................................................................... 5

OPERATION ................................................................................................................................. 6

StartingtheEngine............................................................................................................. 6

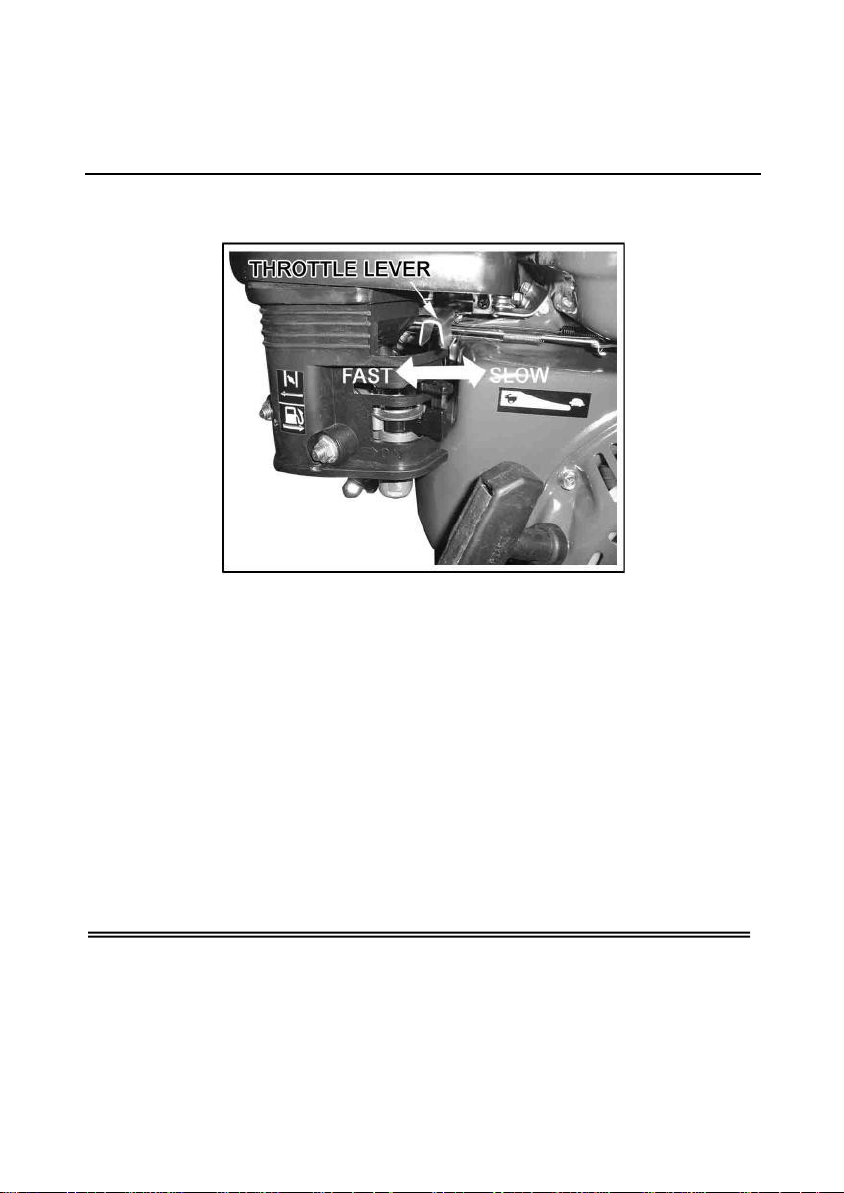

SettingtheEngineSpeed.................................................................................................. 8

STOPPINGTHEENGINE............................................................................................................. 9

SERVICINGTHEENGINE........................................................................................................... 10

MaintenanceSafety............................................................................................................ 10

SafetyPrecautions............................................................................................................. 10

MaintenancePrecautions................................................................................................. 11

Refueling .................................................................................................................... 12

FuelRecommendations .................................................................................................... 12

OilRecommendations ....................................................................................................... 13

OilLevel Check................................................................................................................... 13

OilChange........................................................................................................................... 14

Air Filter Inspection & Service .................................................................................... 15

SedimentCupCleaning..................................................................................................... 16

Spark PlugService ............................................................................................................ 17

IdleSpeedAdjustment....................................................................................................... 18

STORINGTHEENGINE .............................................................................................................. 19

Cleaning ............................................................................................................................. 19

Fuel ............................................................................................................... 19

AddingFuelStabilizer ................................................................................................ 19

Drainingthe Fuel................................................................................................................ 20

EngineOil............................................................................................................................ 20

StoragePrecautions........................................................................................................... 21

RemovalfromStorage........................................................................................................ 21

Transporting ............................................................................................................... 21

TROUBLESHOOTING............................................................................................................................ 22

REMOTE CONTROLLINKAGE(Optional) ................................................................................ 23

HIGHALTITUDEOPERATION.................................................................................................... 24

Replacement Parts .................................................................................................... 24