synthetic 10/40 or 15/40 oil but you will need to add a Zinc Additive to every oil change with these for the

entire life of the engine.

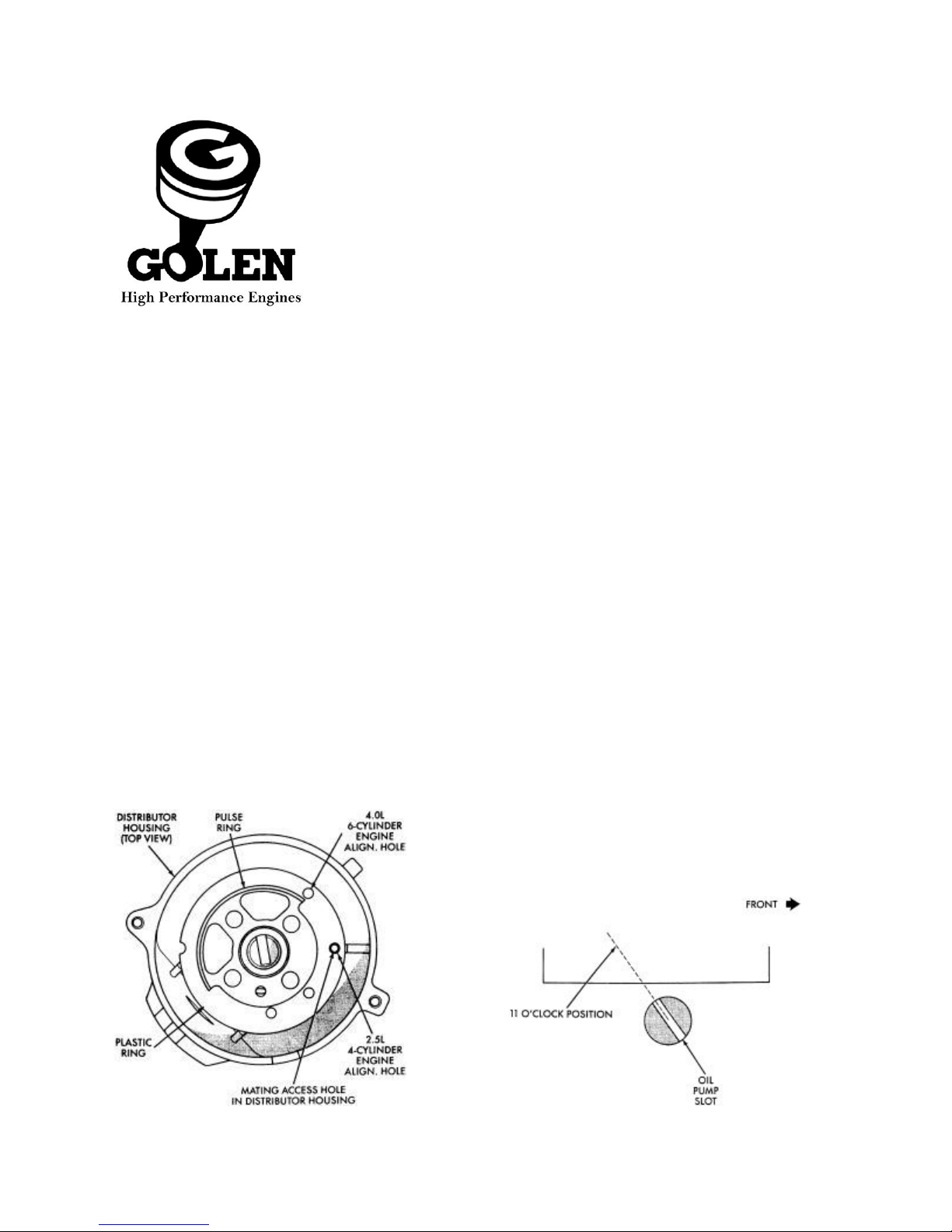

Priming the Oil Pump

At this point you need to prime your engines oil pump. This step is very important and can severely

damage your engine and void your warranty if not performed properly. Please carefully follow the

instructions included in this packet labeled “How to Prime the Jeep Oil Pump” then return to this

page once this is complete.

Installing the Distributor/Cam Sensor

Now you should install the distributor. Follow the instructions included in this packet labeled

“Installing the Jeep Distributor/Cam Sensor” then return to this page.

Starting the Engine

At this point, you are just about ready to start your engine. Reconnect the positive and negative

battery cables and double-check all connections. Once this is complete, call the Golen Engine

tech line at 800-591-9171 ext 2. This is a required part of our standard setup procedure and allows us

to review all of the final details before starting your engine.

Now you are ready to start your new engine. Keep in mind that you must break in the camshaft.

This is just as important as priming the oil as you may also severely damage your engine and

void the warranty by not performing this step. Please follow the instructions in “Jeep Camshaft

Break-In Procedure” then return to this page.

After the cam break-in has been completed, check for leaks. Be sure to check under the vehicle.

Also check the spark plugs. The porcelain should be fairly clean, almost white. Brand new spark

plugs will remain fairly clean after the cam break-in and should not be interpreted as a sign of a

lean condition. If the spark plugs look black or do not look fairly clean after the cam break-in,

please call the Golen Engine tech line at 800-591-9171 ext 2.

Driving the Vehicle

Now it’s time to go for a drive. Run the engine in high gear and lug it checking for detonation

(spark knock or ping). If you experience spark knock call Golen Engine to discuss.

Next make a test run on the road reaching 30mph. Keep this first ride limited to 2-3 miles, then

return and check the spark plugs. They should still be fairly clean, but may start showing a light

brown color that will get slightly darker as you put more miles on the engine. This is a good sign

and means your engine is running properly. If the spark plugs look black please call the Golen

Engine tech line at 800-591-9171 ext 2.

Periodically accelerate to 50mph and decelerate rapidly. Repeat this procedure at least 10 times.

Applying loads to the engine for short periods of time causes increased ring pressure against the

cylinder walls and helps seat the rings. The rapid deceleration increases vacuum and gives extra

lubrication to the piston and ring assemblies. Drive normally but not at continuous high speeds or

under heavy loads for the first 500 miles. It is important to not “lug” or “baby” the engine during

break-in because the rings will not seat properly.

Double check all bolt torques, hose connections, coolant and oil levels. We

recommend that you check these items for the first two weeks of run time. It will take about 500 miles

to break the engine in all the way. It is mandatory to run a Zinc based oil such as the Joe Gibb’s Hot

Rod oil or a Zinc Additive with every oil change for the entire life of the engine.