TS, TR, TX engines workshop manual 10

1.4 Engine Identication

Nomenclature

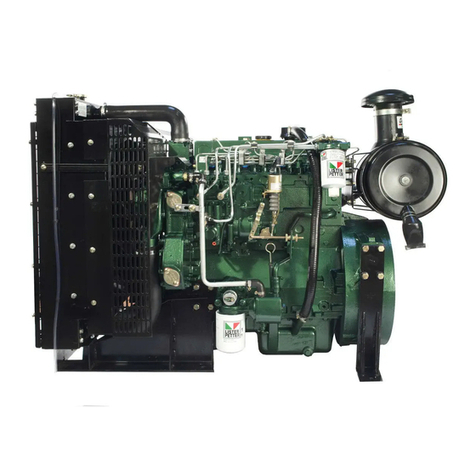

TSandTR - one,twoandthree cylinder,directinjection, naturally

aspirated ywheel fan air cooled diesel engines.

TX - two and three cylinder, direct injection, naturally aspirated,

axial fan air cooled diesel engines.

Engine Serial Number

The engine serial number is stamped on a plate attached to

the engine.

It is necessary to identify the type and build of each engine to

enable the correct maintenance procedures, as described later

in this publication, to be carried out.

An example number is shown below.

03 001234 TS3 A 01

03........................................Year code (03 = 2003)

001234............................... Unique engine number

TS3 ...................................................Engine series

A ......................................... Anti clockwise rotation

01...................................................... Build number

1.5 Battery Details

WARNING

Battery posts, terminals and related accessories contain

lead and lead compounds, chemicals known to the State

of California to cause cancer and reproductive harm.

Wash hands after handling.

WARNING

Sulphuric acid in battery electrolyte is poisonous, is

strong enough to burn skin, eat holes in clothing and

cause blindness if splashed into the eyes.

Battery Polarity

All electric start engines have a 12 or 24 Volt negative earth

system and a 12 Volt ywheel mounted charging system is

available for some TS and TR engine builds.

Recommended Battery Type

HeavyDutyBatteriestoBS3911:982orIEC95-1arerecommended

for all engine applications.

For temperatures below -18°C (0°F), high discharge, low

resistance Arctic or Alkaline batteries must be used.

Lister Petter Power Systems recommend that a battery should

provide a minimum cranking period of 60 seconds from a

70% charged 12 volt battery, with a minimum voltage at the

end of the cranking period of 8.4 volts (16.8 volts on a 24 volt

system).

Preparing a Battery for Use

The following procedure should be used to prepare a battery

with factory sealed charge.

1.Where necessary remove the ash seal in each vent plug hole.

2. Fill with battery grade sulphuric acid of specic gravity 1.260

(1.200 for tropical climates - see Note).The temperature of this

acid should not be above 30°C (90°F) before lling.The correct

level is 6mm (0.25in) above the separator guards.

3. Stand the lled battery for one hour and adjust the acid to

the correct level by adding more acid where necessary.

4. Charge the battery at 6-12 amps for a minimum period of

4 hours.

5. At the end of this charge period the specic gravity of the acid

in any cell should not be less than 1.260 (1.200 for tropical

climates).

If the specic gravity readings are uneven or the specic

gravity low, continue charging until two consecutive half

hourly readings of specic gravity and charge voltage are

approximately the same.

Discontinue charging and allow the battery to cool if the

temperature rises above 40°C (110°F).

Note:

Tropical climates apply to those countries or areas where the average temperature of

any month of the year exceeds 27°C (80°F).

Connecting Batteries

It is most important to ensure that the starter battery, or

batteries, are properly connected and all connections are

tight.

T SERIES ENGINES WORKSHOP MANUAL

10

1.4 ENGINE IDENTIFICATION

Nomenclature

TS and TR - one, two and three cylinder, direct

injection, naturally aspirated flywheel fan air cooled

diesel engines.

TX - two and three cylinder, direct injection, naturally

aspirated, axial fan air cooled diesel engines.

Engine Serial Number

The engine serial number is stamped on a plate

attached to the engine.

It is necessary to identify the type and build of

each engine to enable the correct maintenance

procedures, as described later in this publication,

to be carried out.

An example number is shown below.

03 001234 TS3 A 01

03........................................ Year code (03 = 2003)

001234............................... Unique engine number

TS3...................................................Engine series

A ......................................... Anti clockwise rotation

01...................................................... Build number

1.5 BATTERY DETAILS

WARNING

Battery posts, terminals and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

WARNING

Sulphuric acid in battery electrolyte is poisonous,

is strong enough to burn skin, eat holes in

clothing and cause blindness if splashed into

the eyes.

Battery Polarity

All electric start engines have a 12 or 24 Volt

negative earth system and a 12 Volt flywheel

mounted charging system is available for some TS

and TR engine builds.

Recommended Battery Type

Heavy Duty Batteries to BS3911:982 or IEC95-1 are

recommended for all engine applications.

For temperatures below -18°C (0°F), high discharge,

low resistance Arctic or Alkaline batteries must be

used.

Lister Petter Power Systems recommend that a

battery should provide a minimum cranking period

of 60 seconds from a 70% charged 12 volt battery,

with a minimum voltage at the end of the cranking

period of 8.4 volts (16.8 volts on a 24 volt system).

Preparing a Battery for Use

The following procedure should be used to prepare a

battery with factory sealed charge.

1.Where necessary remove the flash seal in each

vent plug hole.

2.Fill with battery grade sulphuric acid of specific

gravity 1.260 (1.200 for tropical climates - see

Note). The temperature of this acid should not be

above 30°C (90°F) before filling. The correct level

is 6mm (0.25in) above the separator guards.

3.Stand the filled battery for one hour and adjust

the acid to the correct level by adding more acid

where necessary.

4.Charge the battery at 6-12 amps for a minimum

period of 4 hours.

5.At the end of this charge period the specific gravity

of the acid in any cell should not be less than 1.260

(1.200 for tropical climates).

If the specific gravity readings are uneven or the

specific gravity low, continue charging until two

consecutive half hourly readings of specific gravity

and charge voltage are approximately the same.

Discontinue charging and allow the battery to cool

if the temperature rises above 40°C (110°F).

Note:

Tropical climates apply to those countries or

areas where the average temperature of any

month of the year exceeds 27°C (80°F).

Connecting Batteries

It is most important to ensure that the starter

battery, or batteries, are properly connected and all

connections are tight.

Figure 1.5.1 Battery Connections

A - 12 volt system using four 6 volt batteries connected in

series-parallel; B - 12 volt system using two 6 volt batteries

connected in series.

Connecting a Slave Battery

A slave, or booster battery can be connected in

parallel with the existing battery to aid starting in

cold weather conditions.

Figure 1.5.1 Battery Connections

A - 12 volt system using four 6 volt batteries connected in series-parallel;

B - 12 volt system using two 6 volt batteries connected in series.

Connecting a Slave Battery

A slave, or booster battery can be connected in parallel with the

existing battery to aid starting in cold weather conditions.

WARNING

Heavy duty jumper leads must always be used and no

attempt must be made to use any others.

WARNING

Do not allow the jumper lead free ends to directly, or

indirectly touch the engine at any time.