PRODUCT DESIGN

3

G

ENERAL

I

NFORMATION

The MBVC Blower Cabinets are used in combination with a

casedevaporatorcoilfor a two-piece blower and coilcombi-

nation. Thiscombination of blower andcoil functions as the

indoor part of a split air-conditioning system, and may be

matched with a remote condensing or heat pump unit and

allowsfor a variety ofmix-matching possibilities.

The blower cabinet can also function as an electric furnace

whenused with an electric heater.

NOTE: The electric heating elements for electric furnace

installation are not shipped with the cabinet and are field-

installed. Electric heater kits (HKR) are available as sales

accessoriesfor supplemental electric heat.

Systems should be properly sized by heat gain and loss

calculations made according to methods of the Air Condi-

tioning Contractors Association (ACCA) or equivalent. It is

the contractor’s responsibility to ensure the system has ad-

equate capacity to heat or cool the conditioned space.

TheMBVC blower cabinet uses avariable speed motor that

maintains a constant airflow with a higher duct static. It is

approvedforapplicationswithcoolingcoilsofupto0.8inches

W.C. external static pressure and includes a feature that

allows airflow to be changed to + 10%.

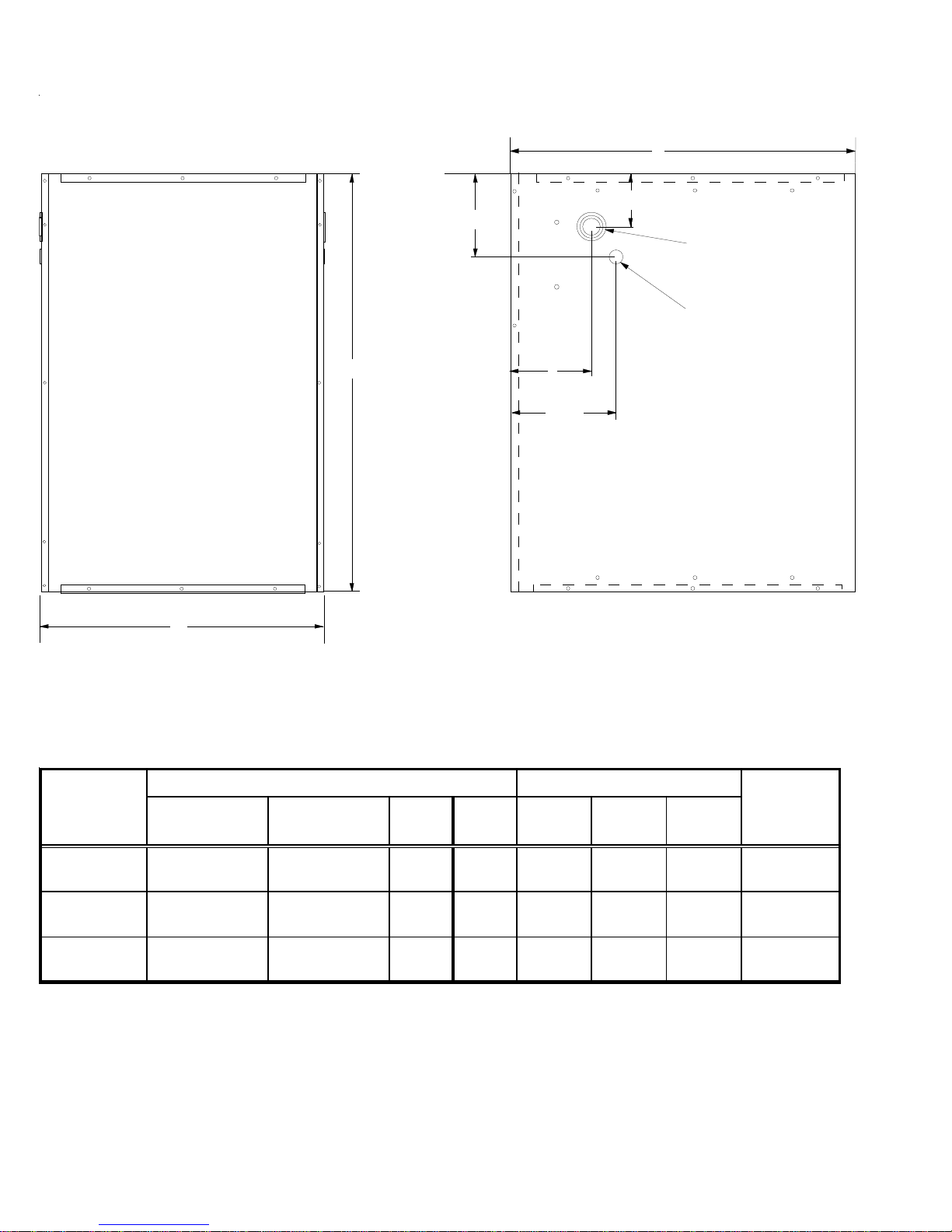

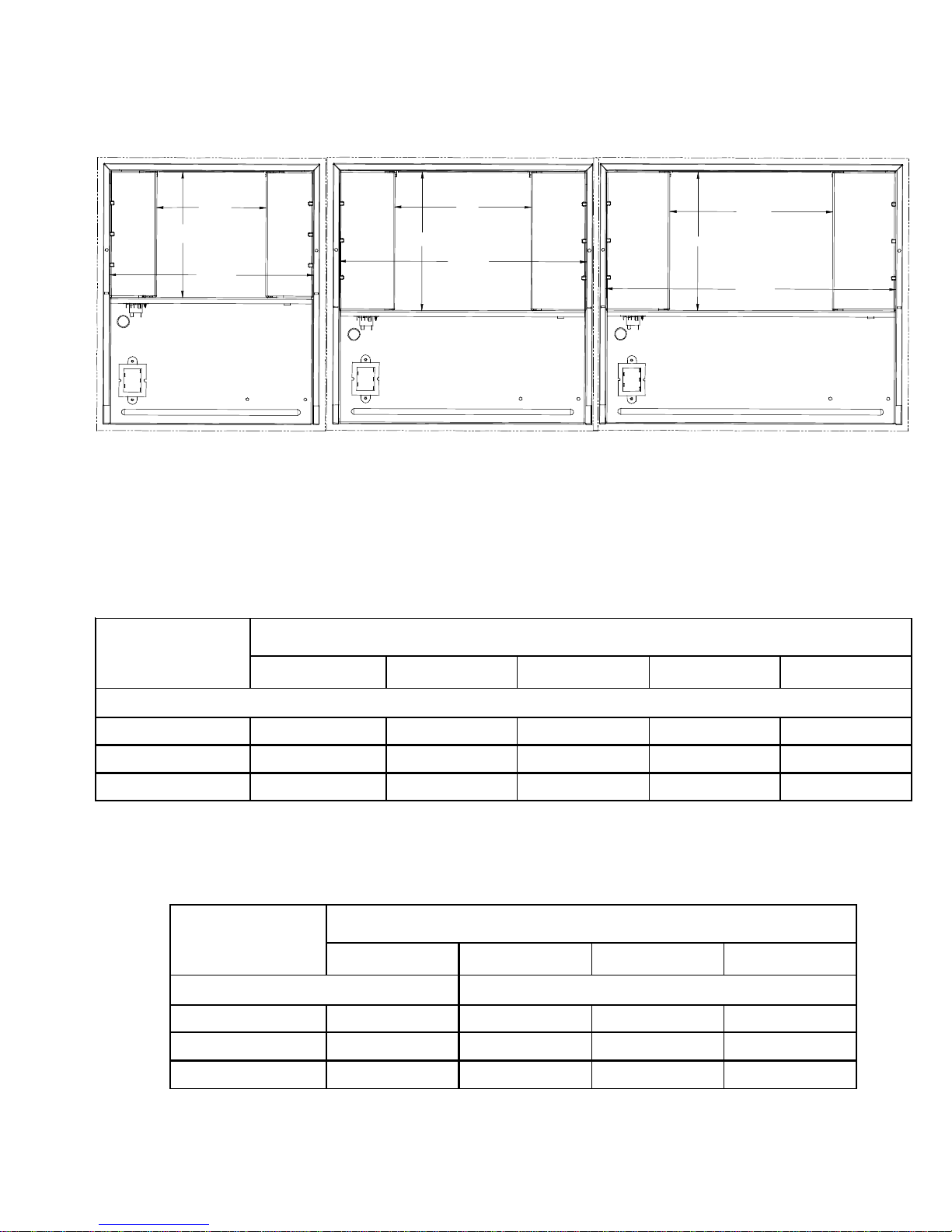

The MBVC blower cabinets, with proper coil matches, can

bepositioned for upflow, counterflow, horizontal right or hori-

zontal left operation. All units are constructed with R-4.2

insulation. In areas of extreme humidity (greater than 80%

consistently), insulate the exterior of the blower with insula-

tionhavingavaporbarrierequivalenttoductwork insulation,

providinglocalcodespermit.

TheCAPX/CHPXcoilsare equipped with a thermostaticex-

pansionvalvethathasabuilt-ininternalcheck valveforrefrig-

erantmetering. TheCACF/CAPF/CHPF coils are equipped

with a fixed restrictor orifice.

Thecoilsare designed for upflow,counterflow,or horizontal

application, using ECM motors on the MBVC models.

FEATURES

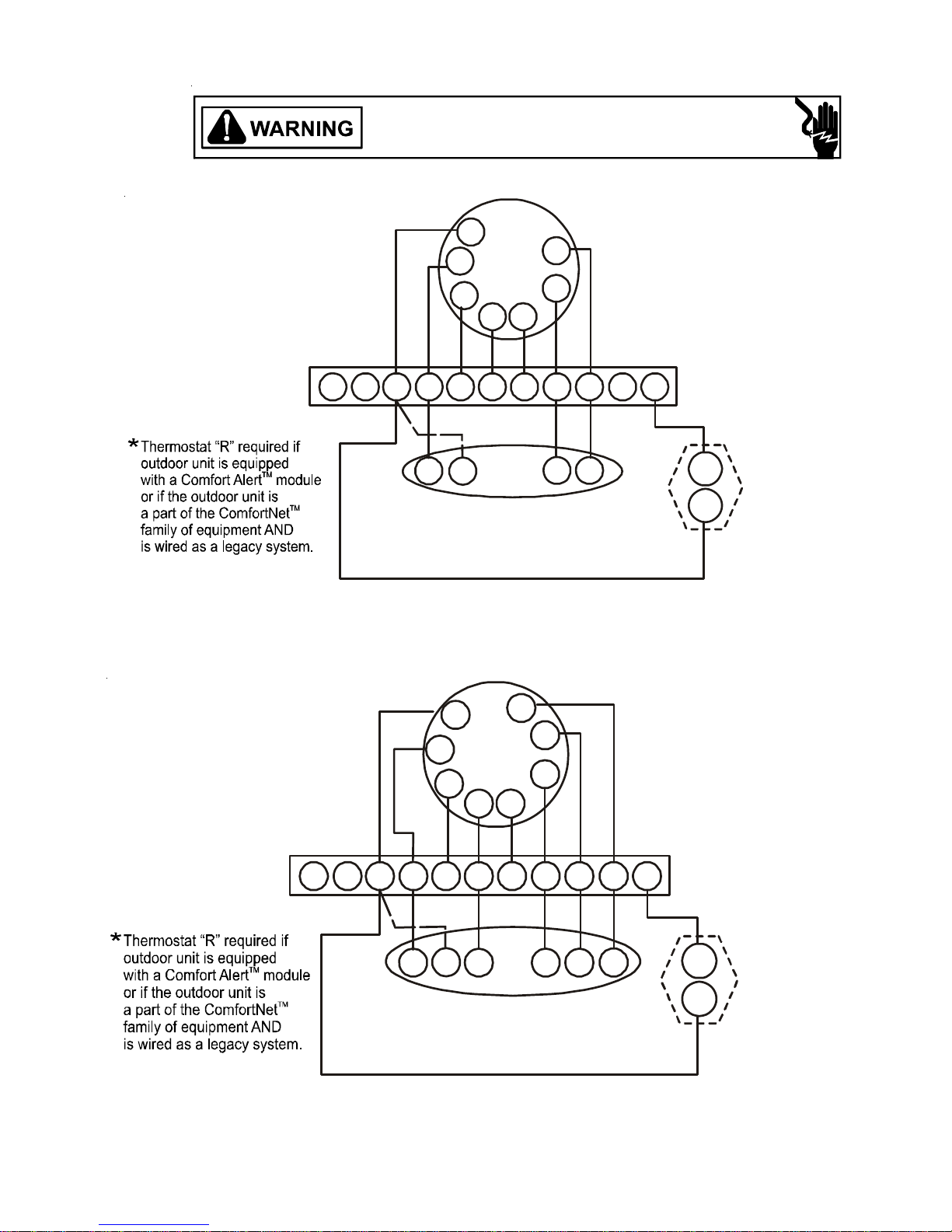

This modular blower is a part of the ComfortNet™ family of

products. It may be installed as part of a “legacy” system

using a standard 24 VAC thermostat. However, with the

CTK01AAComfortNet™thermostatkit, this modular blower

may be installed as part of a digitally communicating sys-

tem. The ComfortNet™ system provides automatic airflow

configuration,enhanced setup features, and enhanceddiag-

nostics. Italso reduces the number of thermostat wiresto a

maximumoffour.

C

OMFORT

N

ET

™S

YSTEM

OVERVIEW

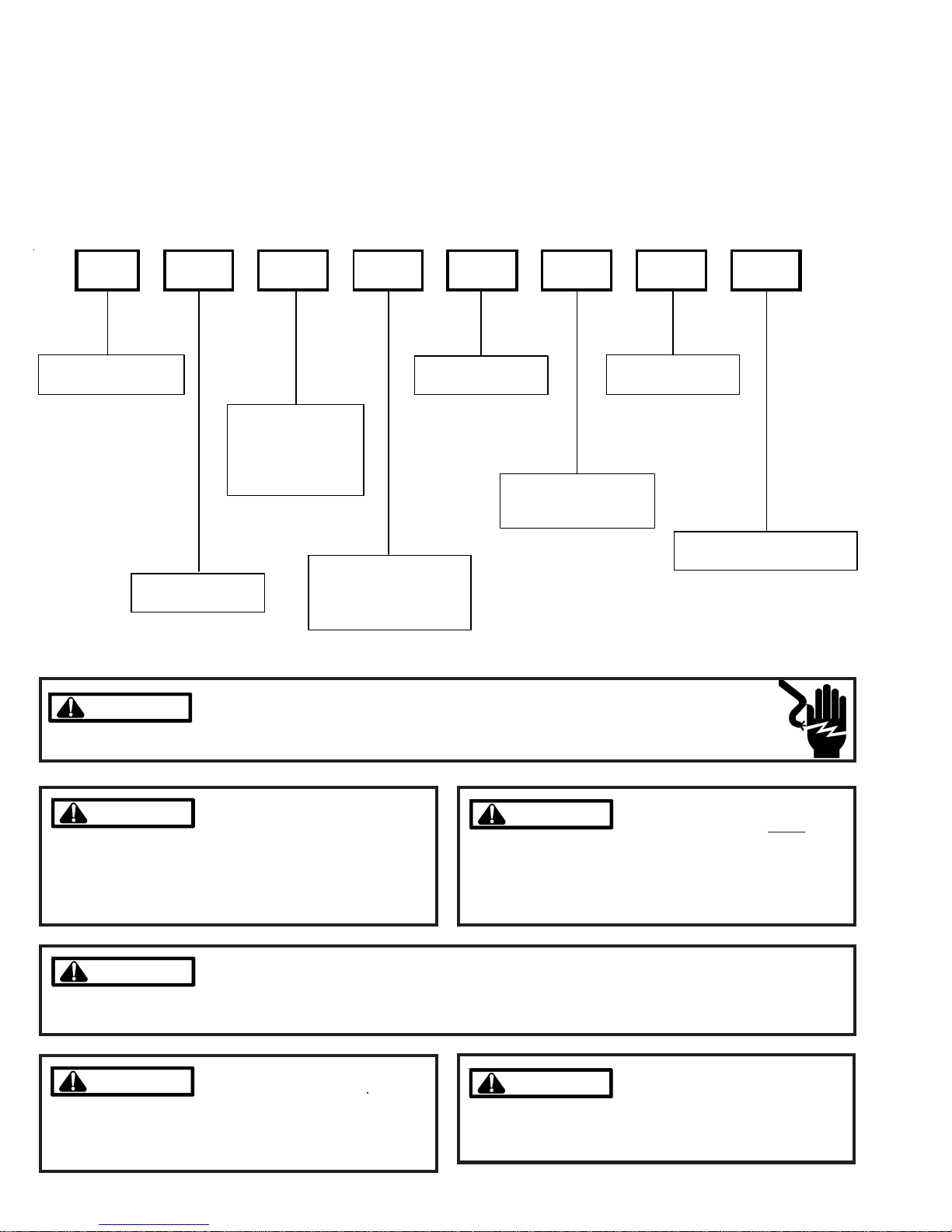

TheComfortNet™system(orCT™system)isasystemthat

includesaComfortNet™compatiblemodular blower and air

conditioner or heat pump with a CTK01AA thermostat. Any

other system configurations are considered invalid

ComfortNet™ systems and must be connected as a tradi-

tional (or legacy) system. The table below compares the

validCT™systems.

CT™ compatible

Modular Blower CT™ compatible

Air Conditioner Full CT™ system

benefits & features

CT™ compatible

Modular Blower CT™ compatible

Heat Pump Full CT™ system

benefits & features

AComfortNet™heating/airconditioning system differs from

alegacy/traditionalsystemin the manner in which the indoor

unit, outdoor unit and thermostat interact with one another.

In a traditional system, the thermostat sends commands to

theindoorandoutdoor units via analog 24 VACsignals. Itis

a one-way communication path in that the indoor and out-

door units typically do not return information to the thermo-

stat.

Ontheotherhand,theindoorunit, outdoor unit, and thermo-

statcomprisingaComfortNet™system“communicate”digi-

tally with one another. It is now a two-way communications

path. The thermostat still sends commands to the indoor

and outdoor units. However, the thermostat may also re-

questand receive informationfrom both theindoor and out-

door units. This information may be displayed on the CT™

thermostat. The indoor and outdoor units also interact with

one another. The outdoor unit may send commands to or

requestinformation from theindoorunit. Thistwo-waydigital

communications between the thermostat and subsystems

(indoor/outdoor unit) and between subsystems is the key to

unlockingthe benefits and features of the ComfortNet™ sys-

tem.

Two-waydigital communications is accomplished using only

twowires. Thethermostatandsubsystemcontrolsarepow-

eredwith 24 VAC Thus, amaximum of 4 wiresbetween the

equipment and thermostat is all that is required to operate

the system.