7

T

O

PREVENT

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

DUE

TO

FIRE

,

DO

NOT

INSTALL

THIS

FURNACE

IN

A

MOBILE

HOME

,

TRAILER

,

OR

RECREATIONAL

VEHICLE

.

WARNING

P

RODUCT

D

ESCRIPTION

FEATURES

This furnace is a part of the ComfortNet™ family of products.

The CTK0* ComfortNet thermostat kit allows this furnace to be

installed as part of a digitally communicating system. The

ComfortNetsystemprovidesautomaticairflowconfiguration,en-

hanced setup features, and enhanced diagnostics. It also re-

duces the number of thermostat wires to a maximum of four. It

may be also installed as part of a non-communicating system

usingastandard24VAC thermostat.

This product may be installed with the ComfortNet thermostat

and a non-ComfortNet compatible single stage air conditioning

unit. However, this reduces the benefits of the ComfortNet sys-

temastheenhancementswillonlyapplytothefurnace.

P

RODUCT

A

PPLICATION

This furnace is primarily designed for residential home-heating

applications. It is NOT designed or certified for use in mobile

homes,trailersorrecreationalvehicles. Neitherisitdesignedor

certifiedforoutdoorapplications. Thefurnacemustbeinstalled

indoors (i.e., attic space, crawl space, or garage area provided

thegarage area is enclosedwithan operating door).

This furnace can be used in the following non-industrial com-

mercialapplications:

Schools, Office buildings, Churches, Retail stores,

Nursinghomes,Hotels/motels,Commonoroffice areas

In such applications, the furnace must be installed with the fol-

lowingstipulations:

• It must be installed per the installation instructions

providedandper localandnationalcodes.

• Itmustbeinstalledindoorsinabuildingconstructedon

site.

• It must be part of a ducted system and not used in a

free air delivery application.

• It must not be used as a “make-up” air unit.

• Itmustbeinstalledwithtwo-pipesystemsforcombustion

air,especiallyifVOC’sorothercontaminantsarepresent

in the conditioned space.

• AllotherwarrantyexclusionsandrestrictionsapplyThis

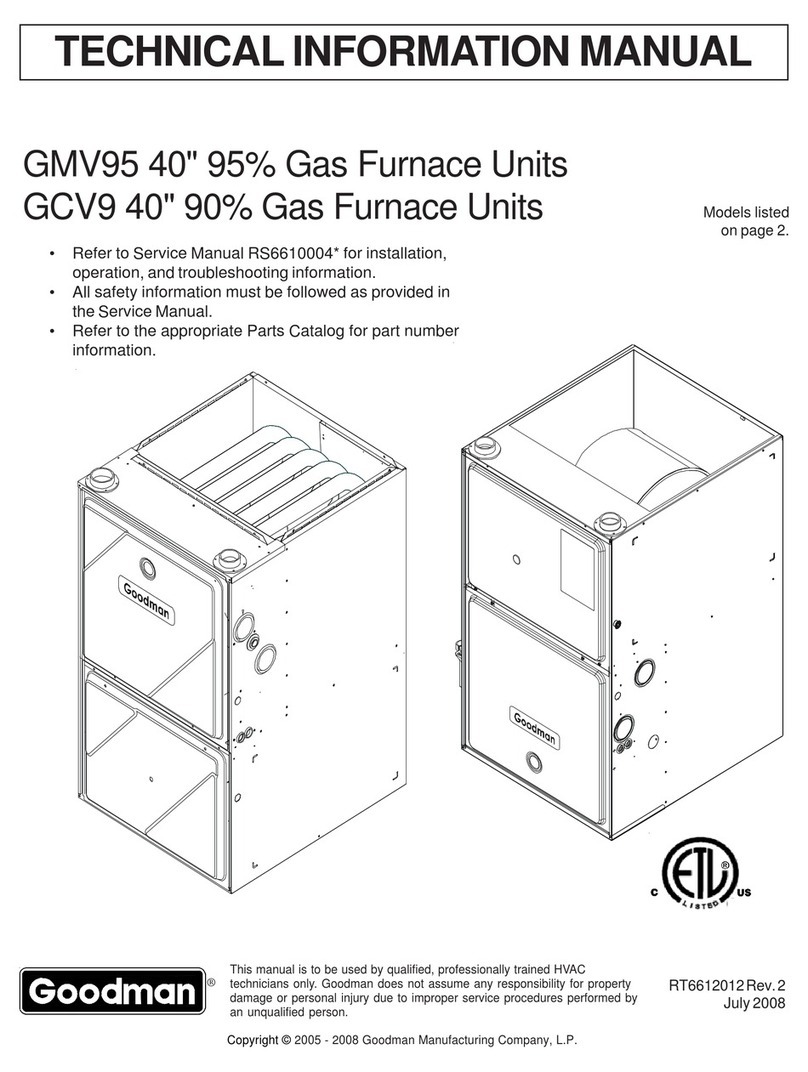

furnace is an ETL dual-certified appliance and is

appropriateforusewithnaturalorpropanegas(NOTE:

Ifusingpropane,apropaneconversionkitisrequired).

Dual certification means that the combustion air inlet pipe is op-

tionaland the furnace can beventedas a:

Non-direct vent (single pipe) central forced air furnace

in which combustion air is taken from the installation

area or from air ducted from the outside or,

Direct vent (dual pipe) central forced air furnace in

whichallcombustion airsupplieddirectlyto thefurnace

burners through a special air intake system outlined in

theseinstructions.

This furnace may be used as a construction site heater ONLY if

allofthefollowingconditions aremet:

• The vent system is permanently installed per these

installationinstructions.

• Aroomthermostatisusedtocontrolthefurnace.Fixed

jumpers that provide continuous heating CANNOT be

usedandcancauselongtermequipmentdamage.

• Returnairductsareprovidedandsealedtothefurnace.

• Areturnairtemperaturerangebetween60ºF(16ºC)and

80ºF(27ºC)ismaintained.

• Airfiltersareinstalledinthesystemandmaintainedduring

constructionreplacedasappropriateduringconstruction,

anduponcompletionofconstruction.

• Theinputrateandtemperaturerisearesetperthefurnace

ratingplate.

• 100% outside air is provided for combustion air

requirementsduringconstruction.Temporaryductingcan

beused.

NOTE:Donotconnectthetemporaryductdirectlytothe

furnace.Theductmustbesizedforadequatecombustion

and ventilation in accordance with the latest edition of

the National Fuel Gas Code NFPA54/ANSI Z223.1 or

CAN/CSAB149.1InstallationCodes.

•Thefurnaceheatexchanger,components,ductsystem,

air filters and evaporator coils are thoroughly cleaned

followingfinalconstructioncleanup.

• Allfurnaceoperatingconditions(includingignition,input

rate,temperatureriseandventing)areverifiedaccording

to these installation instructions.

NOTE: TheCommonwealthofMassachusettsrequiresthatthe

followingadditionalrequirementsmustalsobemet:

• Gasfurnacesmustbeinstalledbyalicensedplumberor

gasfitter.

• AT-handle gas cock must be used.

• Iftheunitistobeinstalledinanattic,thepassagewayto

andtheserviceareaaroundtheunitmusthaveflooring.

To ensure proper furnace operation, install, operate and

maintain the furnace in accordance with these installation

and operation instructions, all local building codes and or-

dinances. In their absence, follow the latest edition of the Na-

tionalFuelGasCode(NFPA54/ANSIZ223.1),and/orCAN/CSA

B149 Installation Codes, local plumbing or waste water codes,

andotherapplicablecodes.