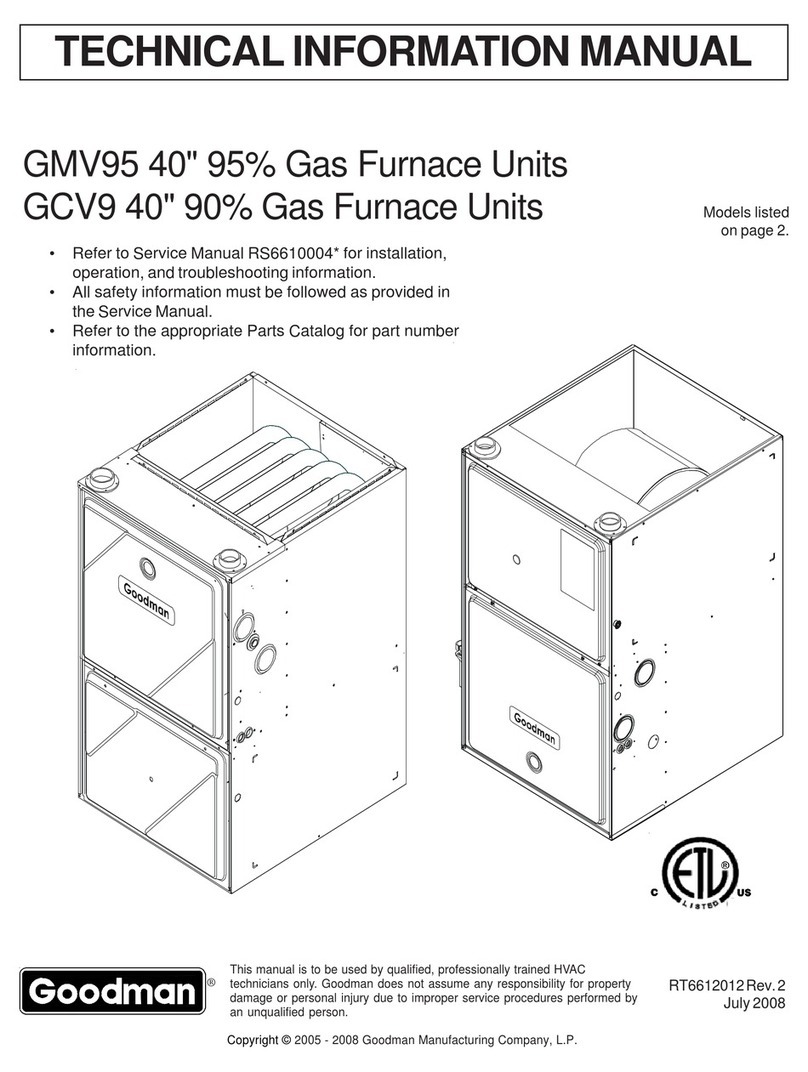

PRODUCT DESIGN

4

4. Installer must supply the following gas line fittings, de-

pendingonwhich entrance is used:

Left --Two 90° Elbows, one close nipple, straight pipe

Right --Straightpipe to reach gas valve.

Accessibility Clearances (Minimum)

POSITION* FRONT SIDES REAR TOP FLUE FLOOR

Upflow30010C

Horizontal 3 6 0 6 0 C

*= All positioning is determined as installed unit is viewed from the front.

C= If placed on combustible floor, floor MUST be wood only.

GMV95 MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS

(INCHES)

NC= For instalaltion on non-combustible floors only. A combustible

subbase must be used for installations on combustible flooring.

36"atfrontisrequiredforservicingorcleaning.

Note: In all cases accessibility clearance shall take

precedence over clearances from the enclosure where

accessibility clearances are greater. All dimensions are

givenininches.

High Altitude Derate

Whenthisfurnaceisinstalledathighaltitude,theappropriate

High Altitude orifice kit must be installed. This is required

due to the natural reduction in the density of both the gas

fuel and combustion air as altitude increases. The kit will

provide the proper design certified input rate within the

specifiedaltituderange.

Natural Propane Natural Propane Natural Propane

GMV950453BX*

GMV950704CX* No

Change LPM-05*

#55 Orifice No

Change

HANG13

#44

Orifice

HALP11

#56 Orifice HAPS28 HANG14

#45

Orifice

HALP11

#56

Orifice HAPS28

GMV950905DX*

GMV951155DX* No

Change LPM-05*

#55 Orifice No

Change

HANG13

#44

Orifice

HALP11

#56

Orifice HAPS29 HANG14

#45

Orifice

HALP11

#56

Orifice HAPS29

9,001 - 11,000 Feet

"STANDARD" and "HIGH ALTITUDE" KITS

Furnace ID Blwr

Pressure

Switch

Gas Orifices

0 - 7,000 Feet

(Standard Altitude) 7,001 - 9,000 Feet

Gas Orifices

ID Blwr

Pressure

Switch

ID Blwr

Pressure

Switch

Gas Orifices

Highaltitudekitsarepurchasedaccordingtotheinstallation

altitudeandusageofeithernaturalorpropanegas.Referto

the chart above for a tabular listing of appropriate altitude

rangesandcorrespondingmanufacturer’shighaltitudeNatural

GasandPropaneGaskits.Foratabularlistingofappropriate

altituderangesandcorrespondingmanufacturer'sHighAltitude

PressureSwitchkits,refertoeitherthePressureSwitchTrip

Points&UsageChartinthismanualortheAccessoryCharts

inServiceInstructions.

GeneralOperation

TheGMV95furnacesareequippedwithanelectronic ignition

device to light the burners and an induced draft blower to

exhaustcombustion products.

An interlock switch prevents furnace operation if the blower

door is not in place. Keep the blower access doors in place

exceptforinspectionand maintenance.

Thisfurnaceisalsoequippedwithaself-diagnosingelectronic

control module. In the event a furnace component is not

operatingproperly,the control module LED willflashon and

off in a factory-programmed sequence, depending on the

problem encountered. This light can be viewed through the

observation window in the blower access door. Refer to the

TroubleshootingChartforfurtherexplanationoftheLEDcodes

andAbnormal Operation - IntegratedIgnitionControlsection

intheService Instructions for an explanation ofthe possible

problem.

The rated heating capacity of the furnace should be greater

than or equal to the total heat loss of the area to be heated.

The total heat loss should be calculated by an approved

method or in accordance with “ASHRAE Guide” or “Manual

J-Load Calculations” published by the Air Conditioning

ContractorsofAmerica.

*Obtain from: American National Standards Institute 1430

BroadwayNewYork, NY10018

LocationConsiderations

• The furnace should be as centralized as is practical

with respect to the air distribution system.

• Do not install the furnace directly on carpeting, tile, or

combustiblematerialotherthanwoodflooring.

• When suspending the furnace from rafters or joists,

use3/8"threadedrod and2”x 2”x1/8”angleasshown

intheInstallationandServiceInstructions.Thelength

ofthe rod willdependonthe application andclearance

necessary.

• Wheninstalledinaresidentialgarage,thefurnacemust

be positioned so the burners and ignition source are

located not less than 18 inches (457 mm) above the

floorand protected from physical damage byvehicles.

Notes:

1. Installermust supply one or two PVC pipes:oneforcom-

bustionair (optional)andone fortheflue outlet(required).

Vent pipe must be either 2” or 3” in diameter, depending

uponfurnaceinput, number of elbows, lengthof run and

installation (1 or 2 pipes). The optional Combustion Air

Pipeisdependent on installation/code requirements and

must be 2” or 3” diameter PVC.

2. Linevoltagewiringcan enter through the right or left side

of the furnace. Low voltage wiring can enter through the

rightor left side of furnace.

3. Conversionkitsfor propane gas and high altitude natural

and propane gas operation are available. See HighAlti-

tudeDeratechart for details.