Table of Contents

PXI 3080/ PCI 3080 – User Manual I

1BOARD INSTALLATION..................................................1-1

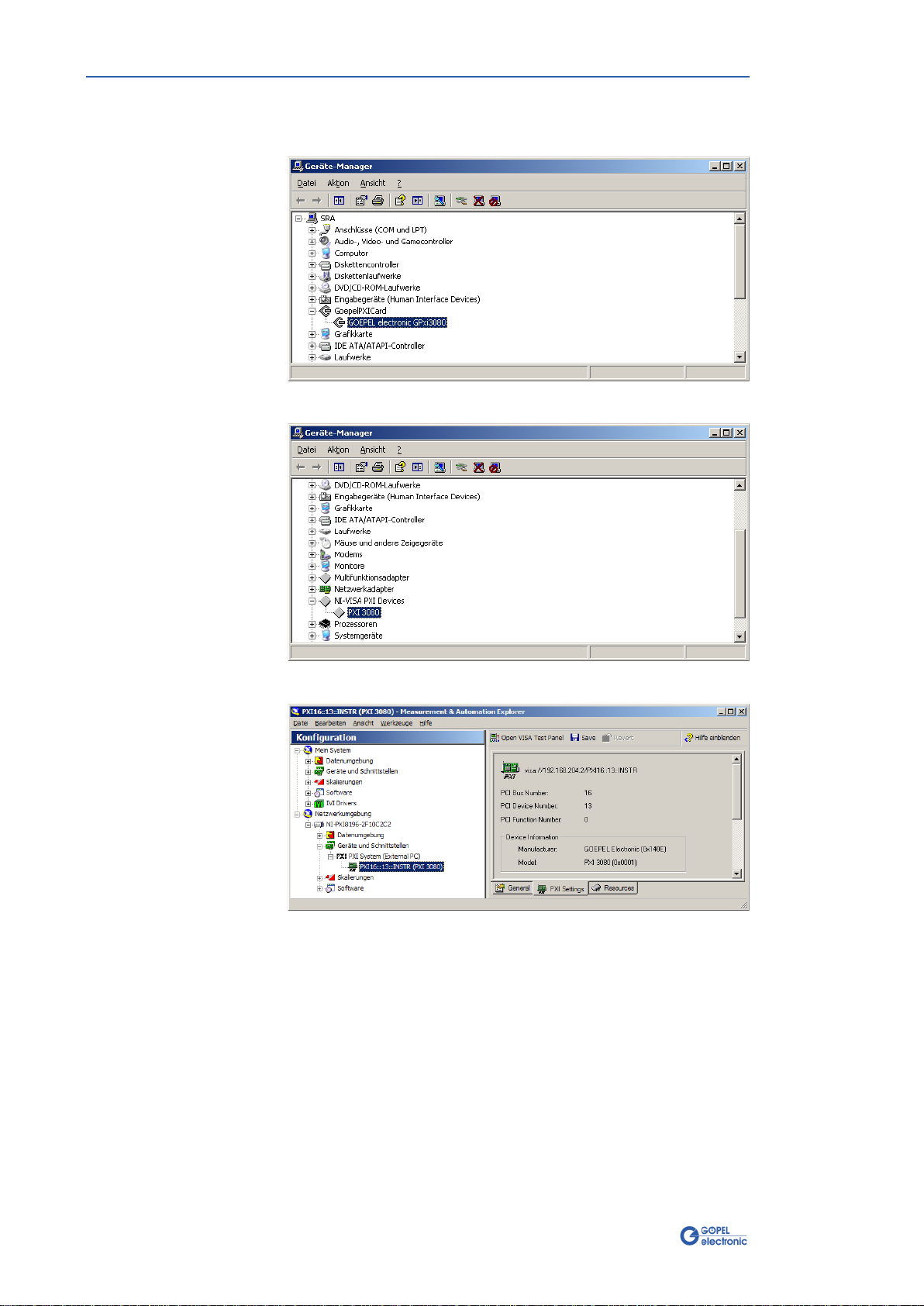

1.1 HARDWARE INSTALLATION ...................................................1-1

1.2 DRIVER INSTALLATION........................................................1-2

1.2.1

Windows Device Driver ...........................................1-2

1.2.2

VISA Device Driver .................................................1-3

2PXI/ PCI 3080 HARDWARE ...........................................2-1

2.1 DEFINITION .....................................................................2-1

2.2 TECHNICAL DATA ..............................................................2-3

2.2.1

General..................................................................2-3

2.2.2

Dimensions ............................................................2-3

2.2.3

PXI 3080/ PCI 3080 Characteristics..........................2-3

2.3 CONSTRUCTION ................................................................2-4

2.3.1

General..................................................................2-4

2.3.2

Addressing.............................................................2-5

2.3.3

Communication Interfaces.......................................2-6

2.3.4

Assembly ...............................................................2-9

2.3.5

Assignment Frontal Plug Connector........................2-11

2.3.6

LED Display..........................................................2-12

2.4 DELIVERY NOTES.............................................................2-13

3CONTROL SOFTWARE....................................................3-1

3.1 PROGRAMMING VIA G-API.FEHLER!TEXTMARKE NICHT DEFINIERT.

3.2 PROGRAMMING VIA DLL FUNCTIONS.......................................3-3

3.2.1

Windows Device Driver ...........................................3-4

3.2.1.1 Driver Info..........................................................3-5

3.2.1.2 DLL Version ........................................................3-6

3.2.1.3 XILINX Download................................................3-7

3.2.1.4 XILINX Write Data...............................................3-8

3.2.1.5 DPRAM Write Instruction .....................................3-9

3.2.1.6 DPRAM Read Response......................................3-10

3.2.1.7 Reset Port ........................................................3-11

3.2.2

VISA Device Driver ...............................................3-12

3.2.2.1 Init...................................................................3-13

3.2.2.2 Done................................................................3-13

3.2.2.3 Driver Info........................................................3-14

3.2.2.4 XILINX Download..............................................3-15

3.2.2.5 XILINX Write Data.............................................3-16

3.2.2.6 Write Data........................................................3-17

3.2.2.7 Read Data ........................................................3-18

3.2.2.8 Reset Port ........................................................3-19

3.3 PROGRAMMING WITH LABVIEW ..........................................3-20

3.3.1

LabVIEW via the G-API .........................................3-20

3.3.2

LLB using the Windows Device Driver.....................3-20

3.3.3

LLB using the VISA Device Driver...........................3-20

3.4 FURTHER GOEPEL SOFTWARE............................................3-20