Table of Contents

PXI 3090/ PCI 3090 – User Manual 1

1BOARD INSTALLATION..................................................1-1

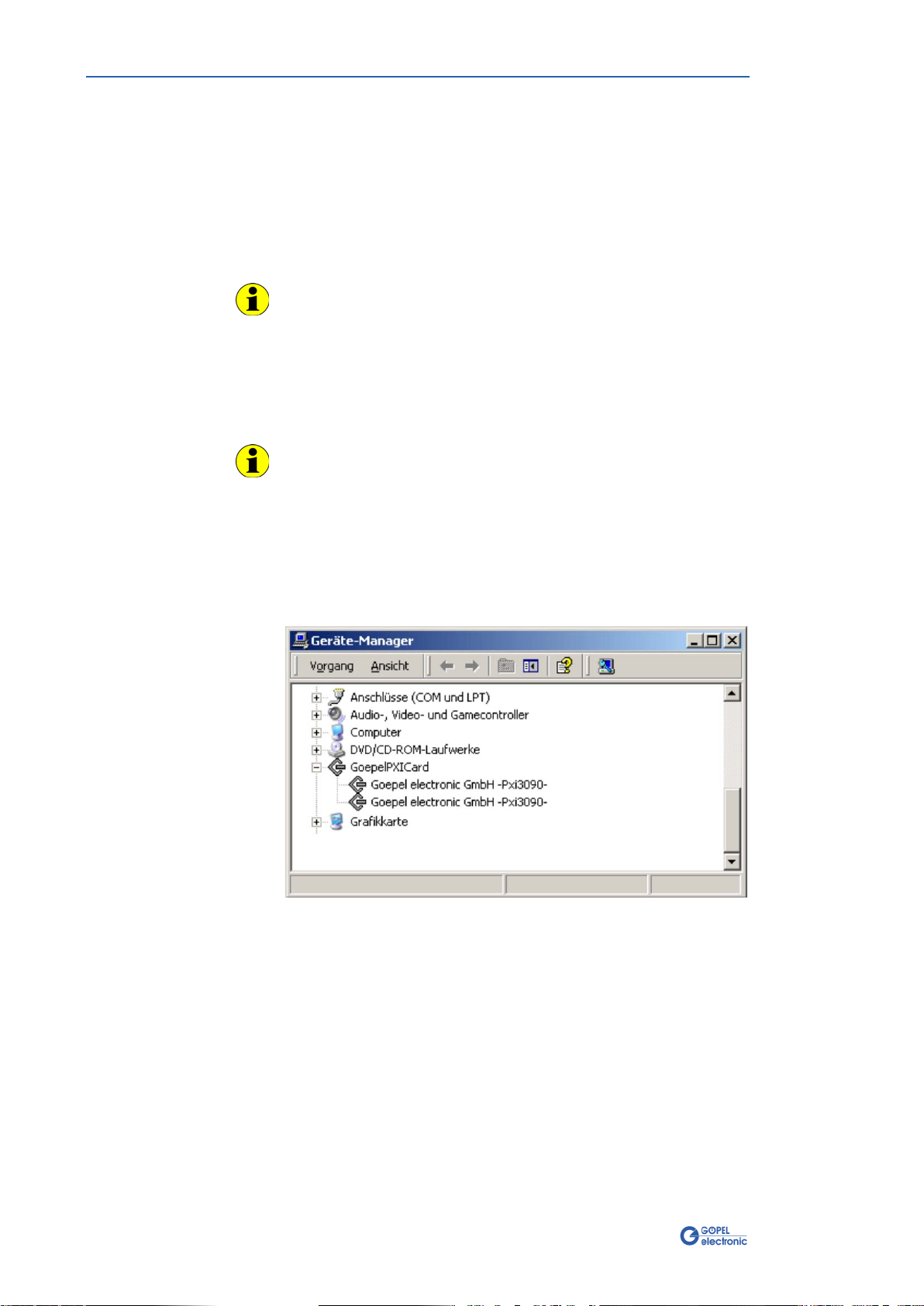

1.1 HARDWARE INSTALLATION ...................................................1-1

1.2 DRIVER INSTALLATION........................................................1-2

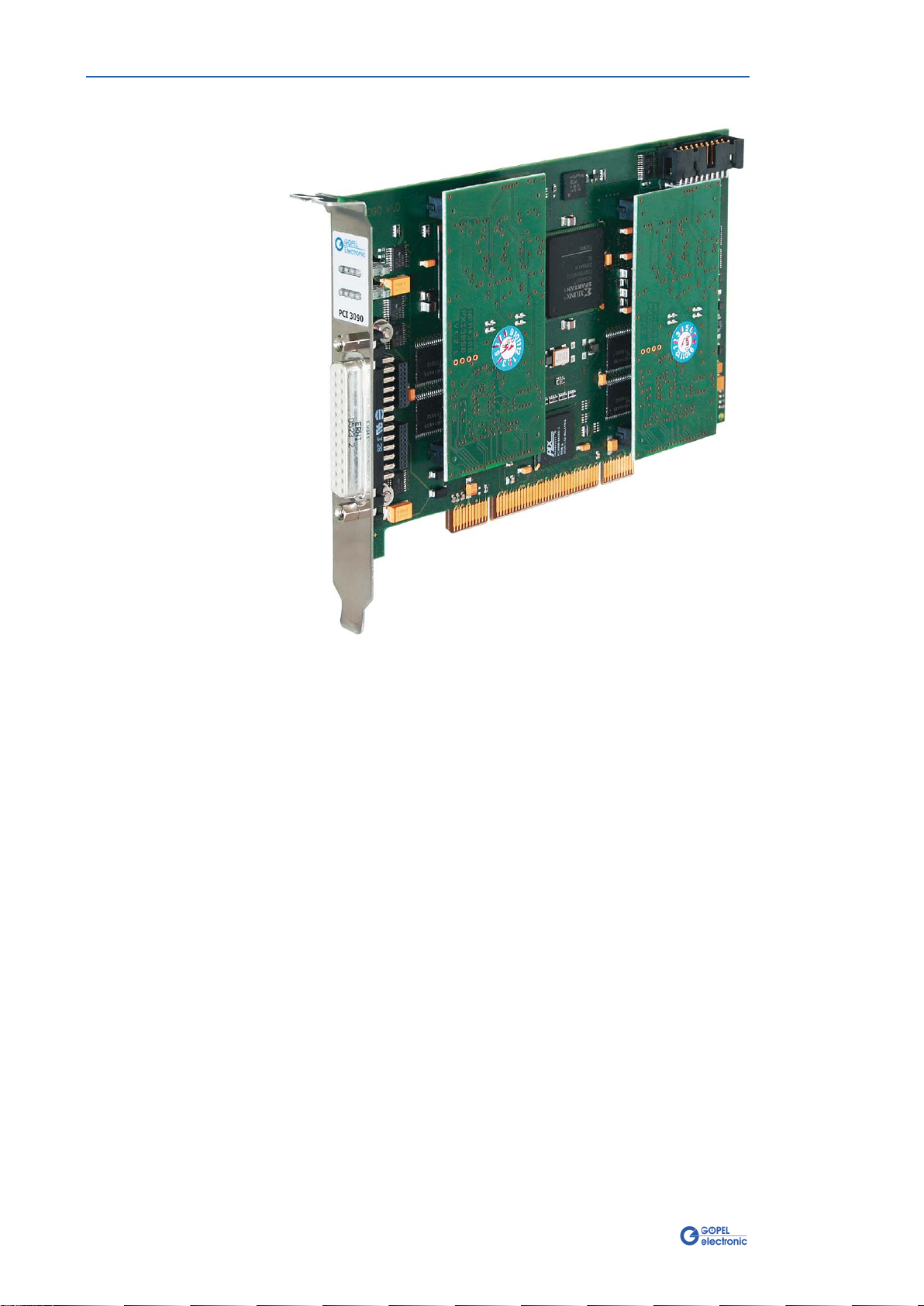

2HARDWARE ...................................................................2-1

2.1 DEFINITION .....................................................................2-1

2.2 TECHNICAL INFORMATION....................................................2-3

2.2.1

General..................................................................2-3

2.2.2

Dimensions ............................................................2-3

2.2.3

3090 Characteristics................................................2-3

2.3 CONSTRUCTION ................................................................2-4

2.3.1

General..................................................................2-4

2.3.2

Addressing.............................................................2-5

2.3.3

Communication Interfaces.......................................2-6

2.3.4

Assembly ...............................................................2-7

2.3.5

Front Connector Pinout ...........................................2-8

2.3.6

LED Indication........................................................2-9

2.4 DELIVERY NOTES...............................................................2-9

3CONTROL SOFTWARE....................................................3-1

3.1 PROGRAMMING VIA G-API...................................................3-1

3.2 PROGRAMMING VIA DLL FUNCTIONS.......................................3-1

3.2.1

Windows Device Driver ...........................................3-2

3.2.1.1 Driver Info..........................................................3-3

3.2.1.2 Write Instruction.................................................3-4

3.2.1.3 Read Response ...................................................3-5

3.2.1.4 Read Monitor......................................................3-6

3.2.1.5 XilinxReadWriteRegister.......................................3-7

3.3 PROGRAMMING WITH LABVIEW ............................................3-9

3.3.1

LabVIEW via the G-API ...........................................3-9

3.3.2

LLB using the Windows Device Driver.......................3-9

3.4 FURTHER GOEPEL SOFTWARE..............................................3-9