OM−05813JW SERIES

PAGE 1 − 1INTRODUCTION

SECTION 1 − INTRODUCTION

Gorman-Rupp JW Series submersible and dry well

pumps are suitable for use in either dry or wet well si-

tuations, provided that the appropriate method of

motor cooling is selected. The motors are supplied

by EMOD Motoren GmbH, and a copy of their Oper-

ating Instructions is included with this manual.

Read this manual in conjunction with the

included copy of the Emod Motor

instructions.

The motors are fully submersible, rated IP68 for

depths up to 30m and, if fully submerged, may be

cooled by direct contact with the pumped liquid. If

only partially submerged, or in a dry well, they must

be fitted with a cooling water jacket which is internally

connected to the pumped liquid.

Liquid temperature must not exceed 40_C

to ensure adequate cooling of the motor.

The motors are normally air-filled, but for situations

where a water jacket is not suitable (e.g. handling

sludge or fatty liquids), oil-filled versions are avail-

able. The greater heat conductivity of the oil means

that such motors can be used without a water jacket,

even in partially submerged situations.

Oil-filled motors are not suitable for dry-well applica-

tions.

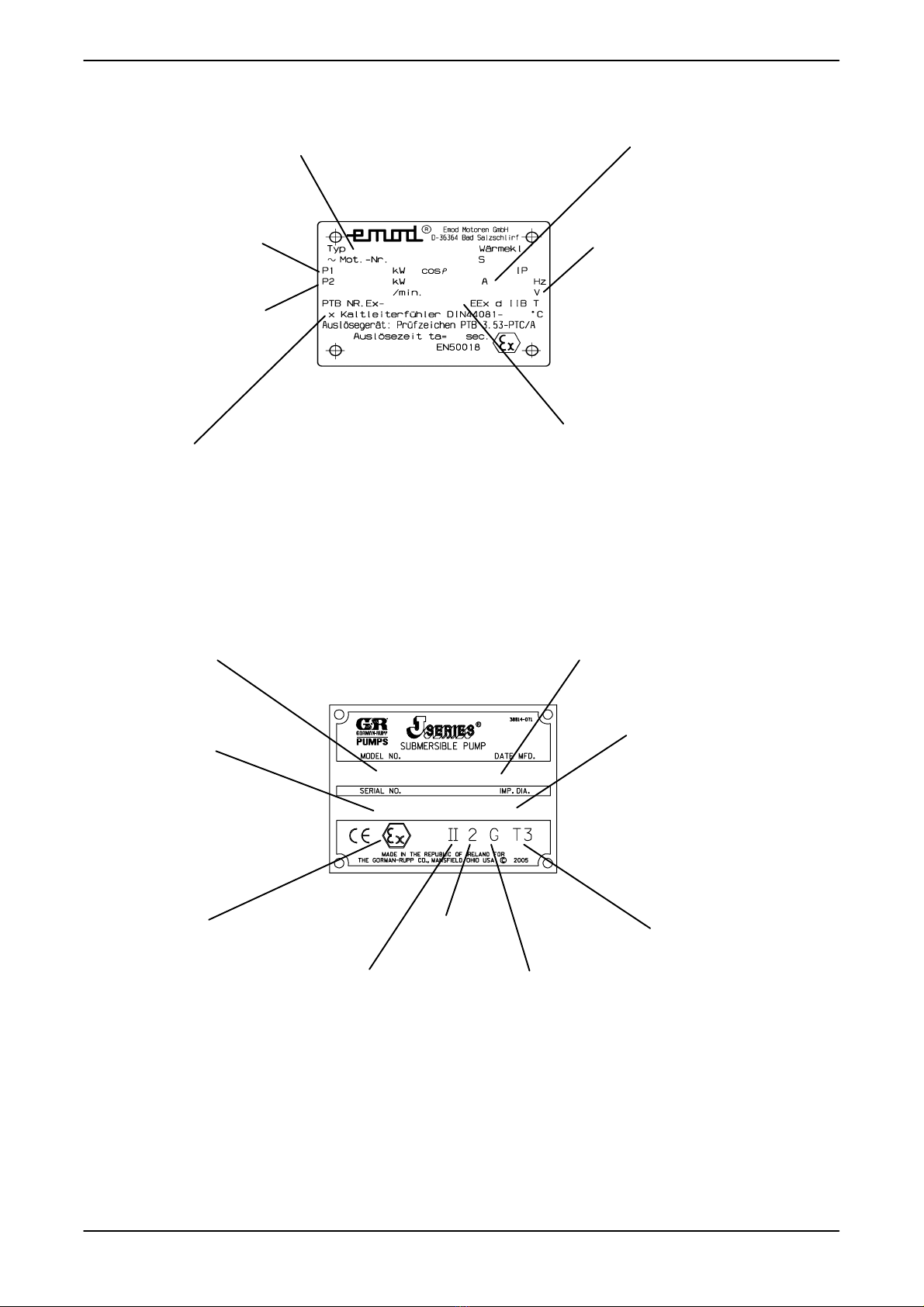

The different types of motors and their methods of

cooling are indicated by the type number on the mo-

tor nameplate:

TMU indicates a motor suitable for safe areas only.

EEx d DPM indicates a motor suitable for Zone 1 or

Zone 2 hazardous areas (see below).

The suffix WK indicates a water jacket.

The suffix O indicates an oil-filled motor.

To avoid leakage of the pumped liquid into the motor,

the shaft is provided with two mechanical seals with a

seal oil chamber between them. There is a moisture-

detection probe in the seal oil chamber which, in con-

junction with the appropriate control equipment, will

indicate if water has leaked past the outer mechani-

cal seal and into the chamber. This gives advance

warning of the need to change a seal before water

has penetrated the motor.

Note that the oil used inside the seal chamber is dif-

ferent from that in the motor (if used) but, as there is

no drain plug on the motor housing, there is no dan-

ger of mixing the two oils or of inadvertently draining

the oil from the motor.

Many wet-well applications are classed as hazard-

ous areas as defined by BS EN 50014. For such ap-

plications, it is mandatory to use equipment which

complies with the requirements of the ATEX Directive

94/9/EG. Pumps and motors suitable for use in haz-

ardous areas Zones 1 and 2 are marked as such on

the nameplates, as shown in Figure 2 in this section.

The ATEX marking on the pump nameplate is II 2 G

T3, which indicates that it is Category 2 of Equipment

Group II, suitable for gaseous atmospheres, and

having a maximum surface temperature of class T3

(200°C). Such marking shows that the equipment is

suitable for Zone 1 and Zone 2.

It is not necessary to have Group II Category 2 equip-

ment independently certified, but it is required that

the Construction File justifying such categorisation is

deposited with a Notified Body". The Construction

File for Gorman-Rupp submersible pumps is depos-

ited with BASEEFA (2001) Ltd, Rockhead Business

Park, Staden Lane, Buxton, Derbyshire, SK17 9RZ,

UK.

A risk assessment has been carried out in

order to comply with the ATEX directive.

This indicates that, if the pump is allowed

to run dry, there is a risk of accumulation

of flammable gases. There is also a risk of

ignition due to contact of moving parts or

to an electrical spark from the moisture