CONTENTS Page CONTENTS Page

GOSSEN-METRAWATT GMBH 3

Safety features and safety precautions .............................................. 4

Maintenance ................................................................................... 5

Repair and replacement parts service ............................................... 5

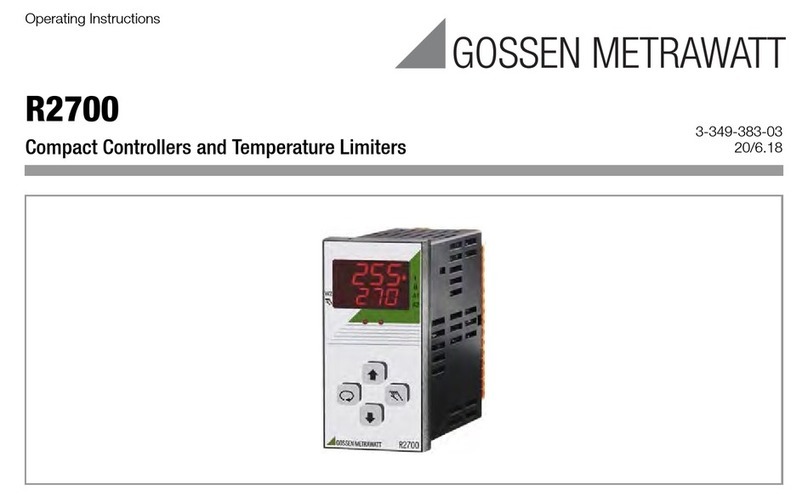

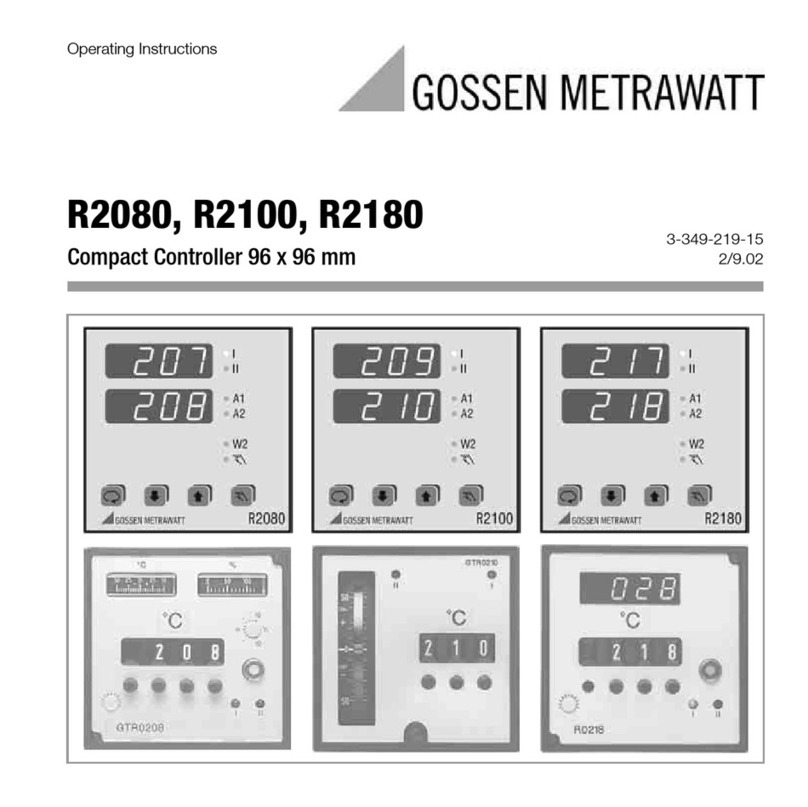

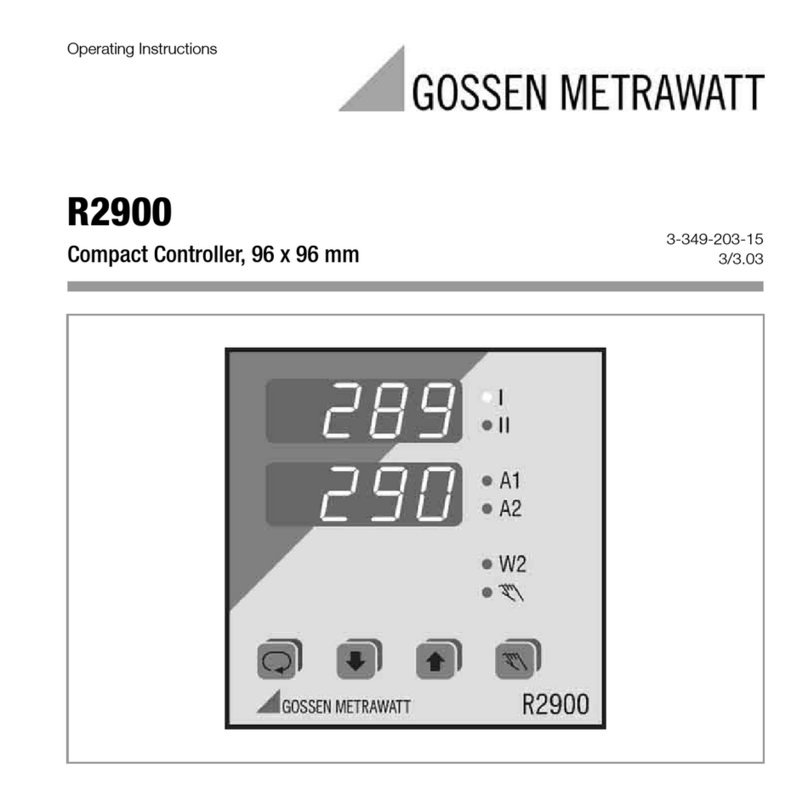

Identifying the unit .......................................................................... 6

Physical installation / Getting started ................................................ 8

Electrical connection ..................................................................... 10

Configuring the switching outputs I and II ........................................ 12

Behavior when the auxiliary voltage is switched on ......................... 12

Operation ..................................................................................... 13

Operational flow diagram „Switching controller“ .............................. 14

Operational flow diagram „Switching controller“ for diff. controller ... 15

Operational flow diagram „Continuous and step controller“ .............. 16

Operat. flow diagr. „Cont. and step controller“ for diff. controller ..... 17

Off / manual mode ........................................................................ 18

Manual mode with binary input 2 .................................................... 19

Feedforward control with binary input 2 .......................................... 19

Configuration ................................................................................. 20

Storage and Uploading of Device Settings ....................................... 23

Differential controller ...................................................................... 24

Slave controller .............................................................................. 24

Controller types ............................................................................. 25

Configuration of the controller with continuous output (marking A3) .. 26

Setting parameters ........................................................................ 28

Calibration .................................................................................... 30

Self-optimizing ............................................................................ 31

Manual optimizing ......................................................................... 32

Set point ramps ............................................................................ 36

Heating current monitor ................................................................. 36

Heating circuit monitor .................................................................. 37

Limit monitor ............................................................................... 38

Alarms ........................................................................................ 39

Error messages ............................................................................ 40

Technical data .............................................................................. 42

Meaning of the symbols on the unit

Instrument approval

Double or reinforced all-insulation

Warning of danger

EC conformity marking

Attention: see documentation

CSA approval mark