Device Description HG G-71912-A | English, Revision 03 | Date: 28.03.2018

3Table of Contents

Content

1 About this Document ............................................................................. 5

2 Introduction............................................................................................. 6

2.1 Interpreter Variants ............................................................................................................ 6

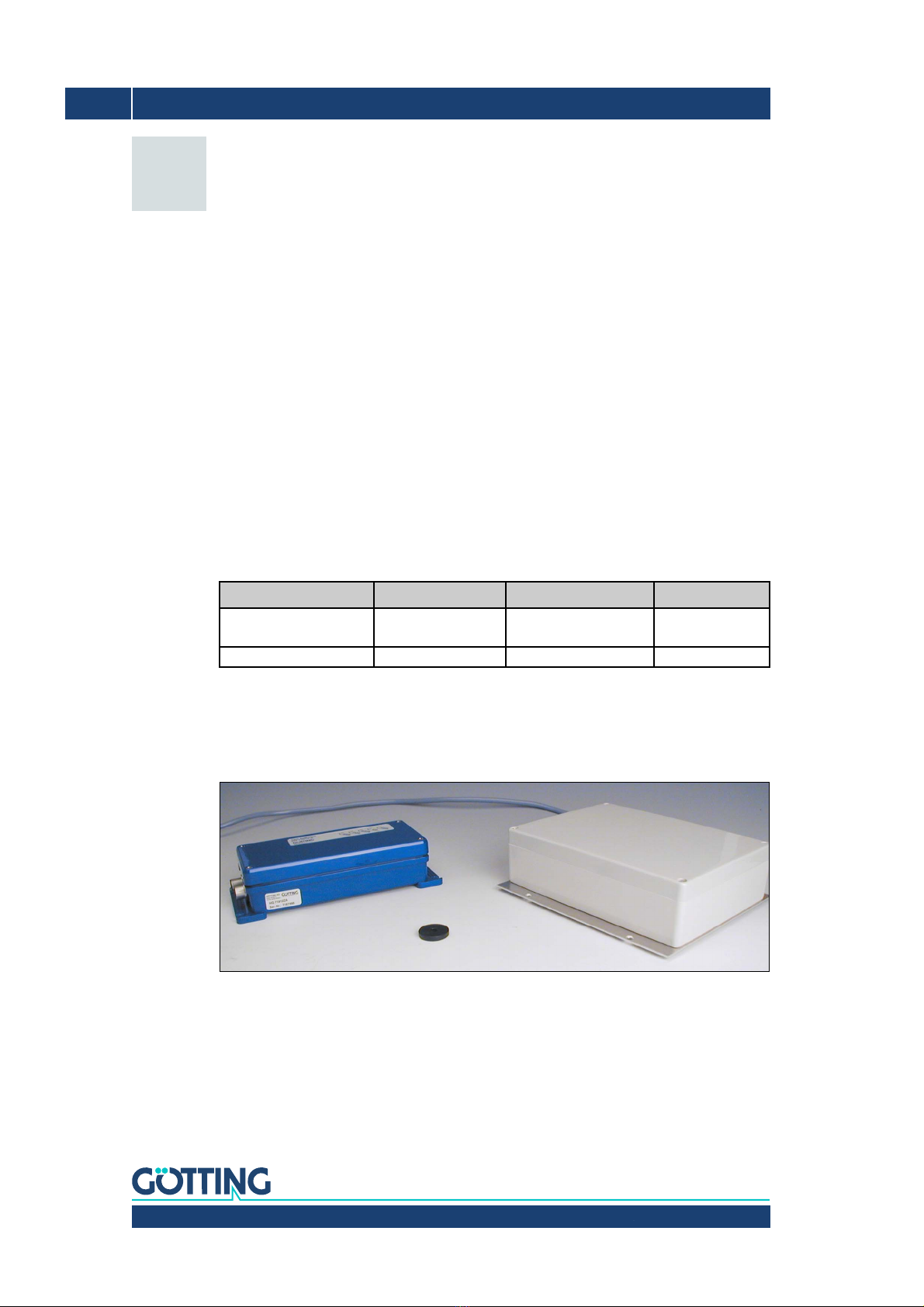

2.2 System Components.......................................................................................................... 6

2.3 Function................................................................................................................................. 7

2.3.1 Surveillance Of The Output Stage.............................................................................................. 7

2.3.2 Switchable reference transponder in the antenna................................................................ 7

2.3.3 Software Update (RS232) ............................................................................................................. 7

3 Mounting ................................................................................................. 8

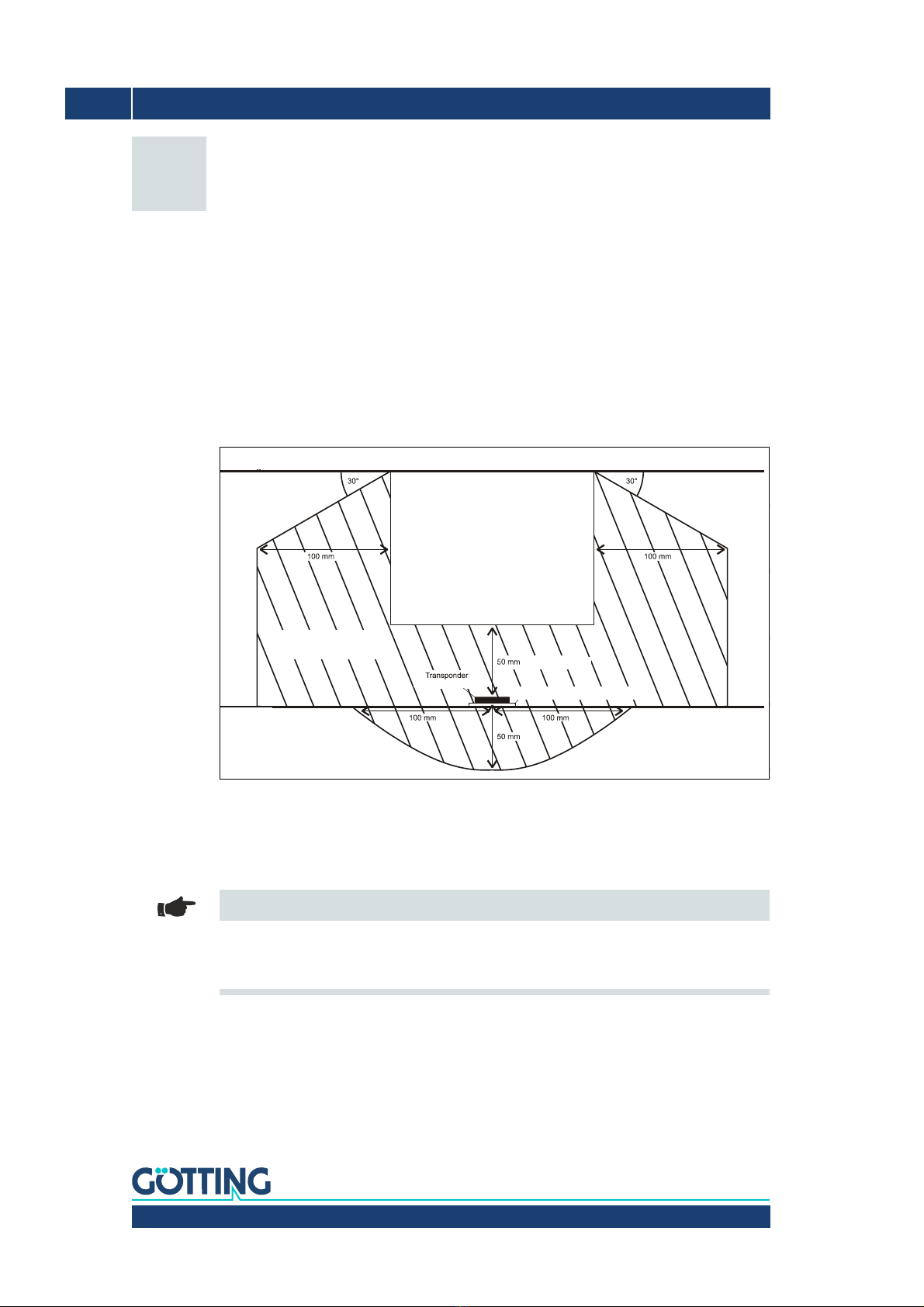

3.1 Transponder ......................................................................................................................... 8

3.2 Interpreter ............................................................................................................................. 9

3.2.1 HG G-71912ZA ................................................................................................................................. 9

3.2.2 HG G-71912YA ................................................................................................................................. 9

3.2.3 HG G-71912XA ...............................................................................................................................10

4 Commissioning ..................................................................................... 11

5 Components and Operation ................................................................ 15

5.1 Underground components .............................................................................................15

5.2 Antenna................................................................................................................................16

5.3 Interpreter HG G-71912-A .............................................................................................16

5.3.1 Pin Allocations / LED ....................................................................................................................17

5.3.1.1 8 pin jack Interpreter <–> Processor....................................................................................17

5.3.1.2 HG G-71912YA: Alloc. of the 26 pin round ribbon cable/ SUB-D connector...........17

5.3.1.3 Control LED..................................................................................................................................18

5.3.2 Interfaces .........................................................................................................................................18

5.3.2.1 RS 232 ...........................................................................................................................................18

5.3.2.1.1 List of System Data that may be Output .....................................................................18

5.3.2.1.2 List Of System Commands ..............................................................................................20

5.3.2.1.3 System Monitor ...................................................................................................................21

5.3.2.2 Positioning Pulse (all Variants) ..............................................................................................21

5.3.2.3 CANopen® (Version HG G-71912ZA/XA)............................................................................21

5.3.2.4 Parallel Port (Version HG G-71912YA) ................................................................................29

6 Software ................................................................................................30

6.1 Terminal Program .............................................................................................................30

6.1.1 Parameter Presetting ...................................................................................................................30

6.2 System Monitor .................................................................................................................31

6.2.1 How to start the monitor program ...........................................................................................31

6.2.1.1 Procedure Monitor Only...........................................................................................................31

6.2.1.2 Procedure 3964R/transparent ...............................................................................................31

6.2.2 How to work with the monitor program.................................................................................32

6.2.2.1 Main Menu ...................................................................................................................................33

6.2.2.2 (W)rite Transponder ..................................................................................................................35

6.2.2.3 (S)erial Interface .........................................................................................................................35

6.2.2.4 P(a)rallel Interface......................................................................................................................37