Device Description HG G-84300ZC | English, Revision 08 | Date: 28.05.2020

3

Table of Contents

Content

1 About this Document........................................................................ 5

1.0.1 Warning Notices ............................................................................................................... 5

1.0.2 Symbols ............................................................................................................................... 6

2 Introduction....................................................................................... 7

3 Hardware ........................................................................................... 8

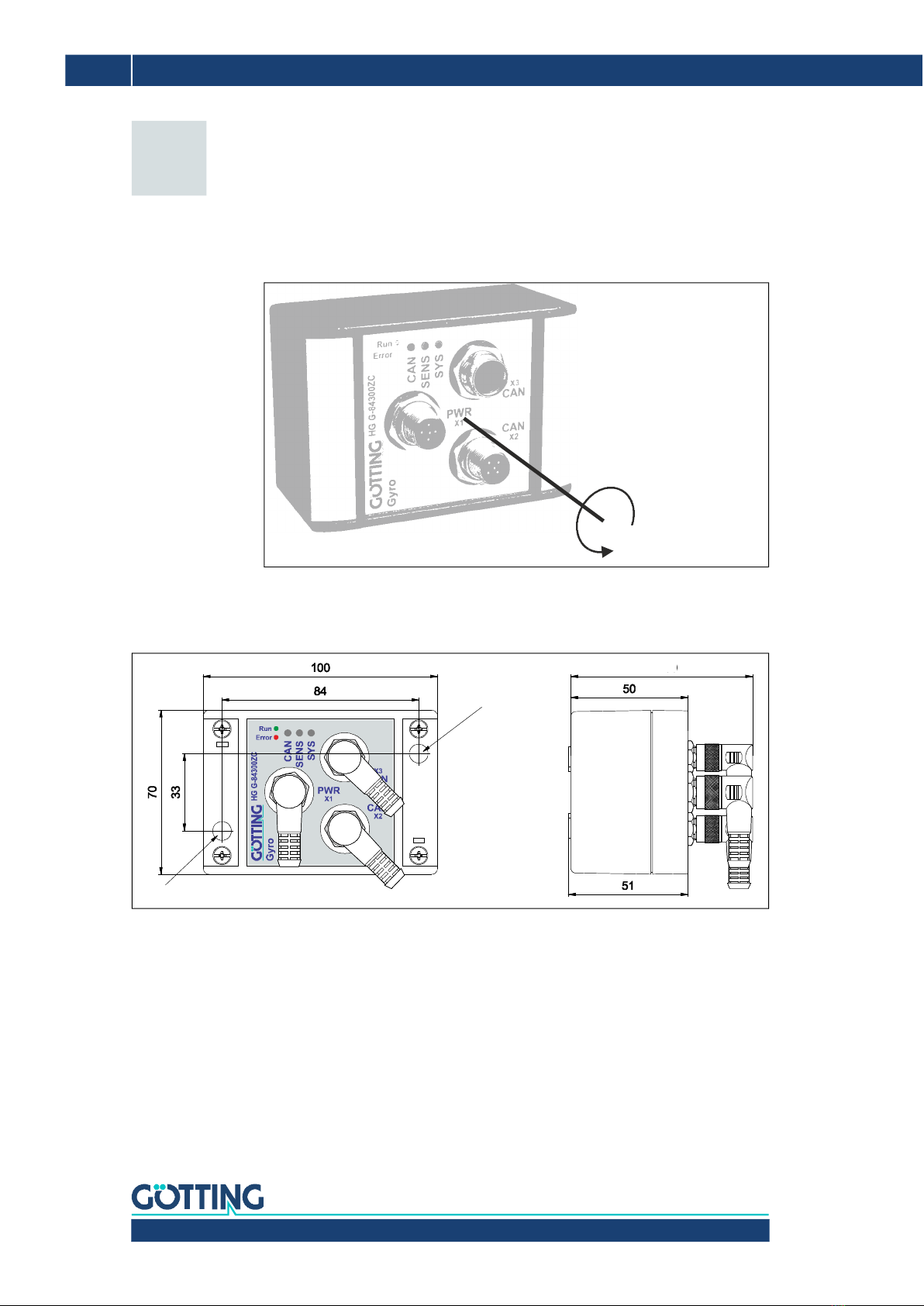

3.1 Alignment of the Measuring Axis..................................................................................... 8

3.2 Dimensions ............................................................................................................................. 8

3.3 Mounting ................................................................................................................................. 8

3.4 Pin Assignment...................................................................................................................... 9

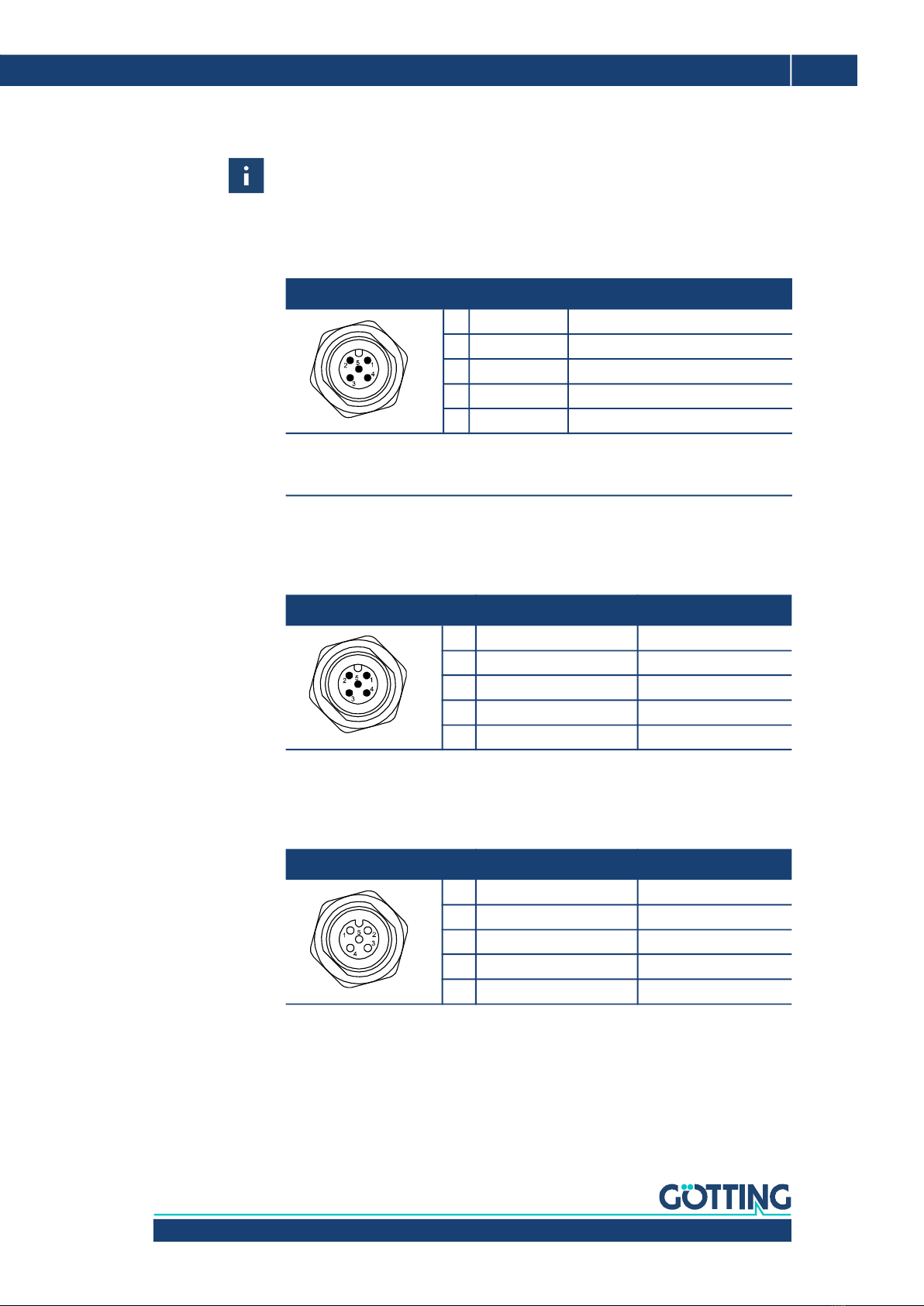

3.4.1 X1 (PWR/USB) ................................................................................................................... 9

3.4.2 X2 (CAN).............................................................................................................................. 9

3.4.3 X3 (CAN).............................................................................................................................. 9

3.5 LEDs ........................................................................................................................................10

3.6 Error Messages ....................................................................................................................11

4 Drift Compensation / Angle Reset ................................................. 12

4.1 Drift Compensation ............................................................................................................12

4.2 Angle reset............................................................................................................................13

5 Configuration via USB .................................................................... 14

5.1 USB Interface .......................................................................................................................14

5.2 Terminal Program ...............................................................................................................14

5.3 Terminal Output In Monitor Mode ................................................................................. 15

5.3.1 Terminal Output for CAN Standard .......................................................................... 15

5.3.2 Terminal Output for CANopen®................................................................................. 16

5.4 Logging (CSV) ......................................................................................................................17

5.5 Firmware Update ................................................................................................................17

6 CAN Bus Interface .......................................................................... 20

6.1 Receiving Box ......................................................................................................................20

6.2 Transmitter Box...................................................................................................................21

7 CANopen® Interface ....................................................................... 22

7.1 Description of the Process Data Objects (PDOs) ......................................................22

7.1.1 Transmission Objects ....................................................................................................22

7.1.2 Reception Object ............................................................................................................23

7.2 Heartbeat...............................................................................................................................23

7.3 Description of the Service Data Objects (SDOs).......................................................24

7.4 Object Directory ..................................................................................................................24

7.4.1 Communication Specific Entries ...............................................................................24

7.4.2 Standardized Device Profile Range .......................................................................... 26

7.4.3 CANopen® Object Dictionary .....................................................................................26

7.4.3.1 Device Type .................................................................................................................26

7.4.3.2 Error Register ..............................................................................................................26

7.4.3.3 COB-ID SYNC message............................................................................................27

7.4.3.4 Device Name ............................................................................................................... 27

7.4.3.5 Hardware Version.......................................................................................................27

7.4.3.6 Software Version........................................................................................................27

7.4.3.7 Producer Heartbeat Time ........................................................................................27

7.4.3.8 Identity Object.............................................................................................................27

7.4.3.9 Receive PDO Parameter...........................................................................................28

7.4.3.10 Mapping RPDO_1.......................................................................................................28

7.4.3.11 Transmit PDO_1 Parameter....................................................................................28