List of contents

3

List of contents

Introduction...............................................................................................................................................................................2

List of contents .........................................................................................................................................................................3

General ......................................................................................................................................................................................4

Ferromagnetism ...................................................................................................................................................................4

Conditions of supply and guarantee......................................................................................................................................5

Delivery ................................................................................................................................................................................6

General ..........................................................................................................................................................................6

Identification plate...........................................................................................................................................................6

ATEX Markings (if applicable).........................................................................................................................................7

ATEX explosive zone measures .....................................................................................................................................8

Safety.........................................................................................................................................................................................9

General.................................................................................................................................................................................9

Danger of magnetic field .....................................................................................................................................................10

Danger of high voltage........................................................................................................................................................11

Danger of dust explosion ....................................................................................................................................................11

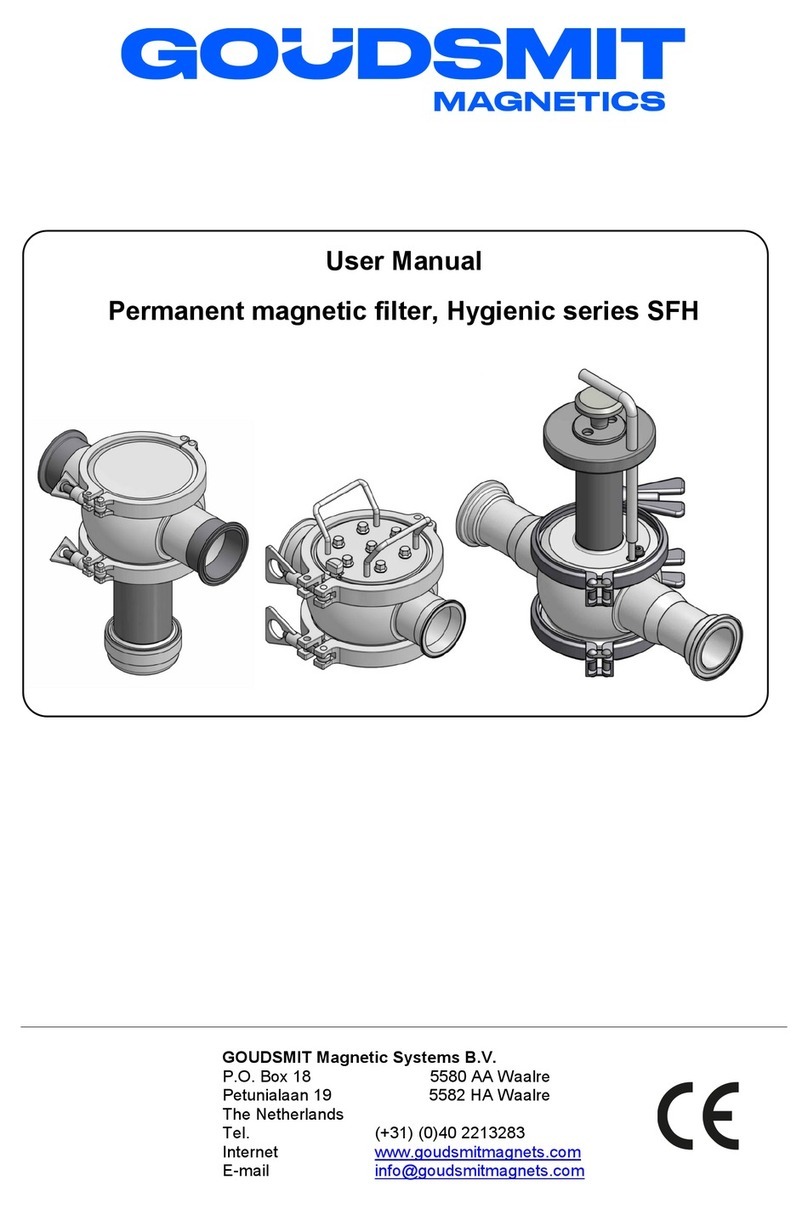

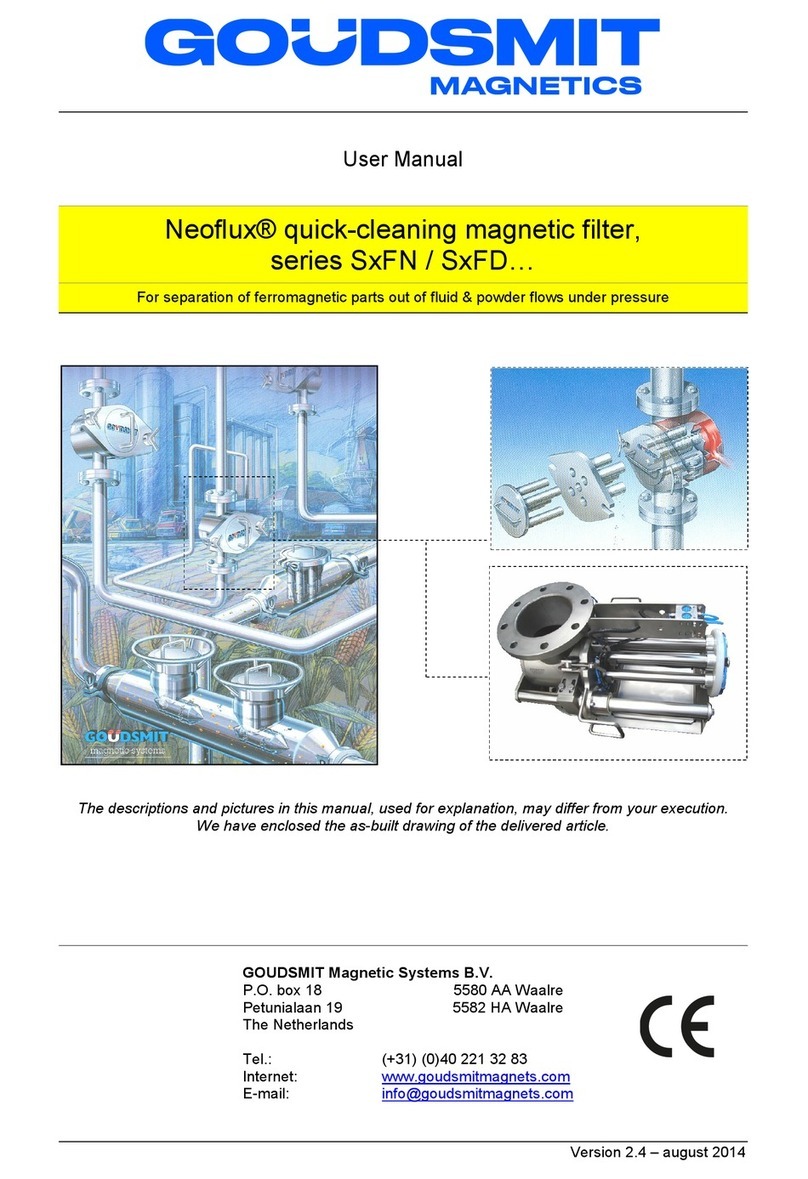

Device description ..................................................................................................................................................................12

Intended use / user indications ...........................................................................................................................................12

Deliverable specials............................................................................................................................................................13

Working principle ................................................................................................................................................................14

Standard Construction ........................................................................................................................................................15

Magnetic bar housings remarks ..........................................................................................................................................16

Installation...............................................................................................................................................................................17

Placing and transport procedures .......................................................................................................................................17

Gasket material / grounding................................................................................................................................................17

Electrical connections general ............................................................................................................................................18

Electrical motor installation (For Cleanflows without control box) ..................................................................................18

Connecting the control box ...........................................................................................................................................19

Electrical connections in control box .............................................................................................................................20

Electrical connections & EX..........................................................................................................................................20

Start-up....................................................................................................................................................................................21

Checks before and during start-up ......................................................................................................................................21

Maintenance ............................................................................................................................................................................22

Cleaning the rotor (Fe parts disposal) .................................................................................................................................22

Cleaning & ATEX................................................................................................................................................................22

Cleaning if rotor is mounted to housing.........................................................................................................................23

Cleaning rotor arm versions..........................................................................................................................................24

Motor reductor ....................................................................................................................................................................25

Malfunctions/Service ..............................................................................................................................................................26

Spare parts..............................................................................................................................................................................27