4

REQUIREMENTS TO THE SOURCE WATER

ATTENTION! The reverse osmosis system performance directly depends on a pressure in a

water conduit. If a pressure in your water conduit is less than 3 atm., that it is necessary to

complement the reverse osmosis system with the booster pump.

The water pressure at the inlet of the system with a pump, atm. 2-8

The water pressure at the inlet of the system without a pump, atm. 3-8

pH 3-11

Water temperature, °С +4...+40

Mineralization, mg/l no more than 1,500

Summary concentration of chlorides, mg/l no more than 1,200

Turbidity, mg/l no more than 1

Hardness, mg-equ/l no more than 7

Iron (Fe2+), mg/l no more than 0.3

Iron (Fe3+), mg/l no more than 0.3

Manganese (Mn), mg/l no more than 0.1

Nitrates, mg/l no more than 45

Permanganate oxygen consumed, mg О2/l no more than 10

Total microbial number, CFU/ml no more than 1,000

Coli-index 1

Higher values of indicators require the additional preliminary purication.

ATTENTION! If characteristics of the source water do not comply with the specied

requirements, that the operating life of the membrane and replaceable ltering modules can

be smaller than the operating life stated in this manual.

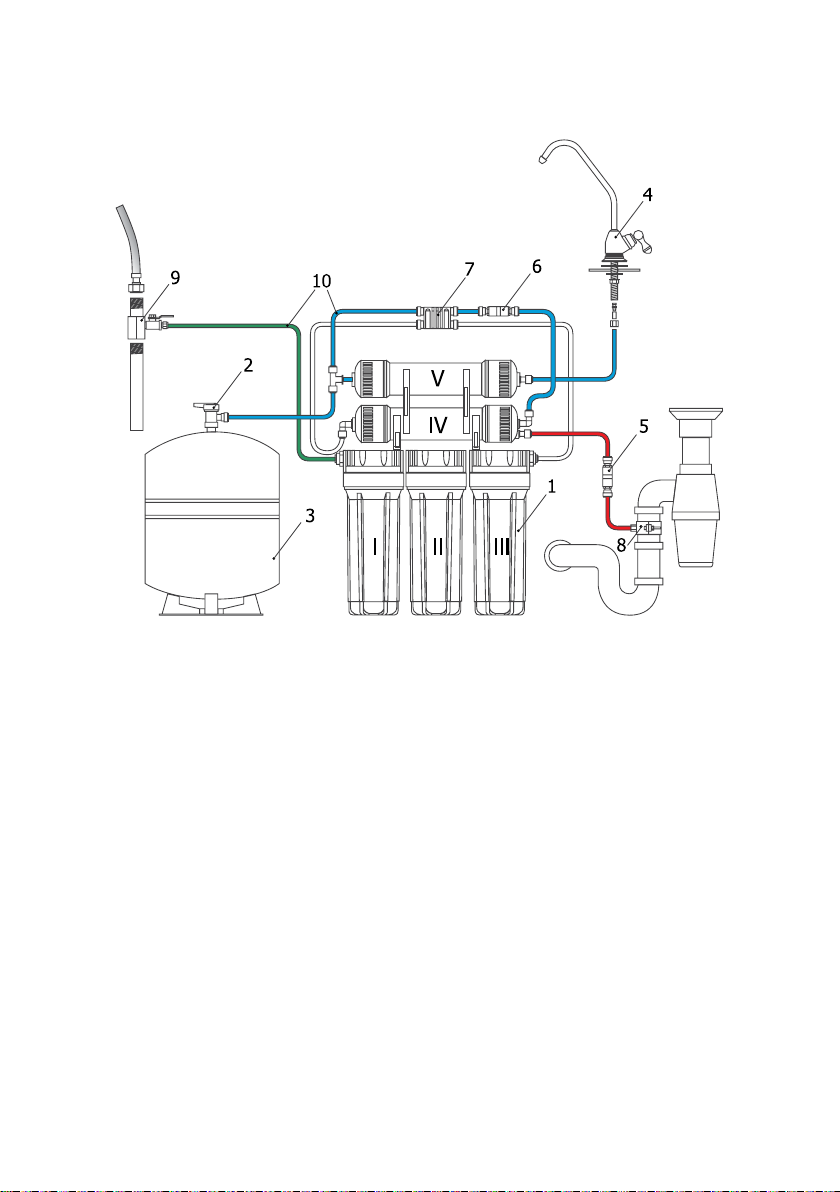

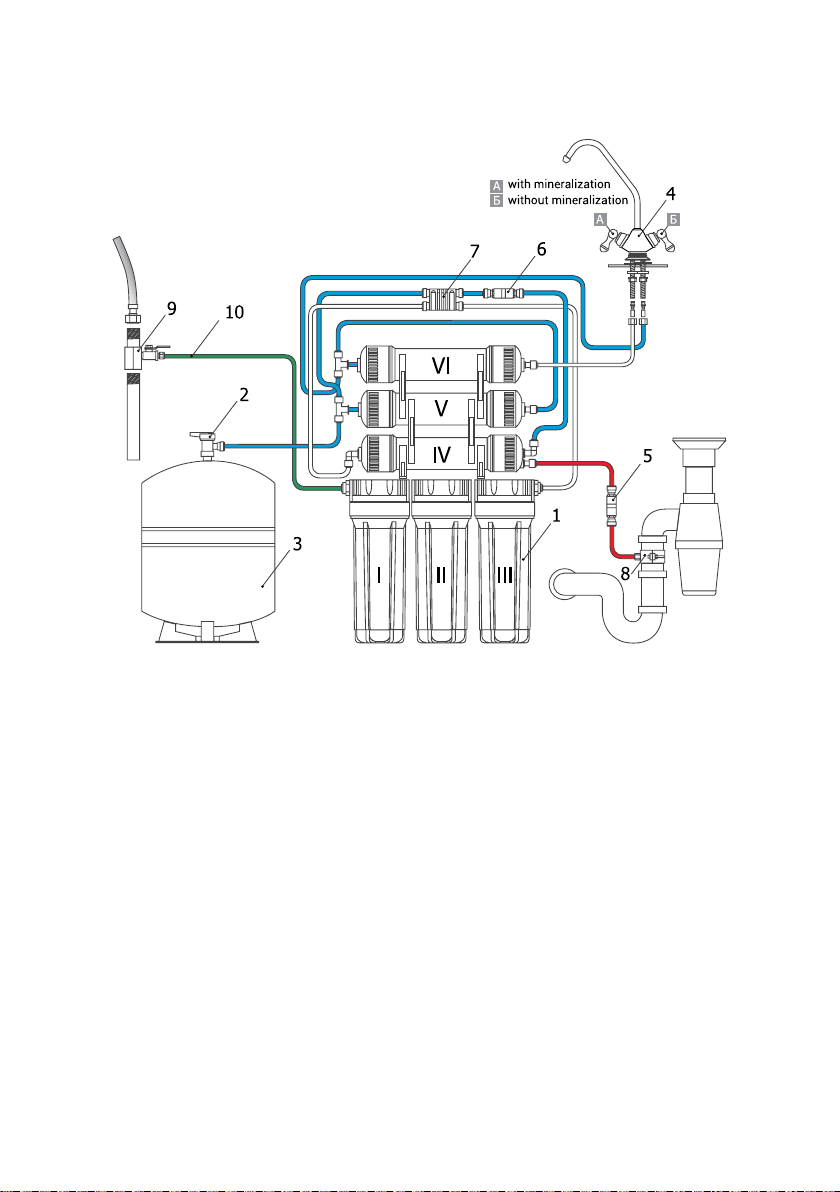

CONNECTION

RECOMMENDATIONS FOR CONNECTION AND OPERATION

the connection is carried out only by the qualied specialist or the manufacturer’s

representative;

strictly follow the manual in case of individual connection;

all lter cases were tested for sealness and hydraulic impact, that is why there is on

water inside cases of the lter;

it is not recommended to disassemble factory connections without the need.

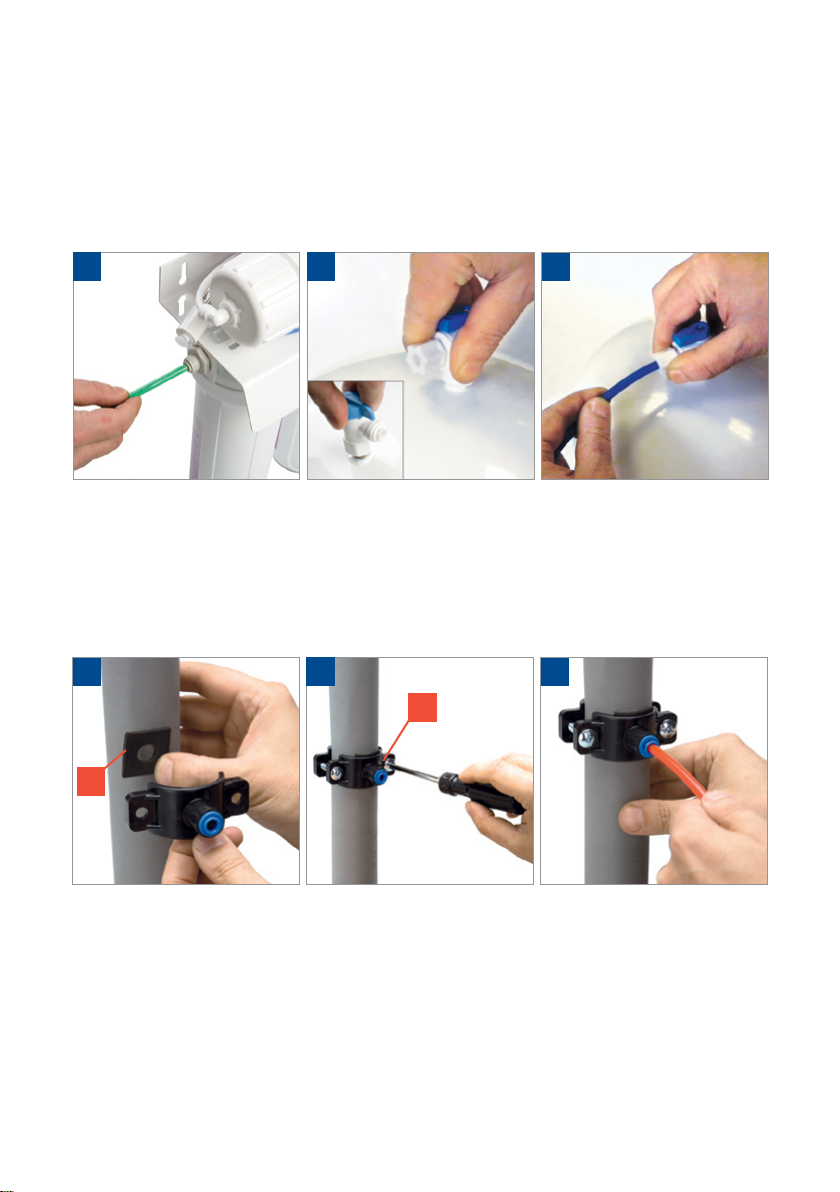

PREPARATION TO THE CONNECTION

1. Shut off the cold water feed to the connection point

(Fig.1) and discharge a pressure by opening the mixer.

2. Make sure that the lter flasks are reliably tightened*.

Tighten them, if necessary.

1

*Periodically check a reliability of the lter flasks tightness and

tighten them, if necessary.

Attention! A position of the vertical label, which is placed strictly

align the lter front center, does not guarantee the connection

leakproofness. A position of the label can be changed during

tightening of the flask screwed connection.