List of contents

User manual Neoflux® quick-cleaning magnetic filter 4

List of contents

Version overview of standard manual.....................................................................................................................................2

Introduction...............................................................................................................................................................................3

List of contents.........................................................................................................................................................................4

General ......................................................................................................................................................................................5

Ferromagnetism ...................................................................................................................................................................5

Conditions of supply and guarantee......................................................................................................................................6

Delivery ................................................................................................................................................................................7

General ..........................................................................................................................................................................7

Identification plate ..........................................................................................................................................................7

Description ATEX certification ........................................................................................................................................8

ATEX explosive zone measures.....................................................................................................................................8

Safety.........................................................................................................................................................................................9

General ................................................................................................................................................................................9

Danger of dust explosion ......................................................................................................................................................9

Danger of magnetic field.....................................................................................................................................................10

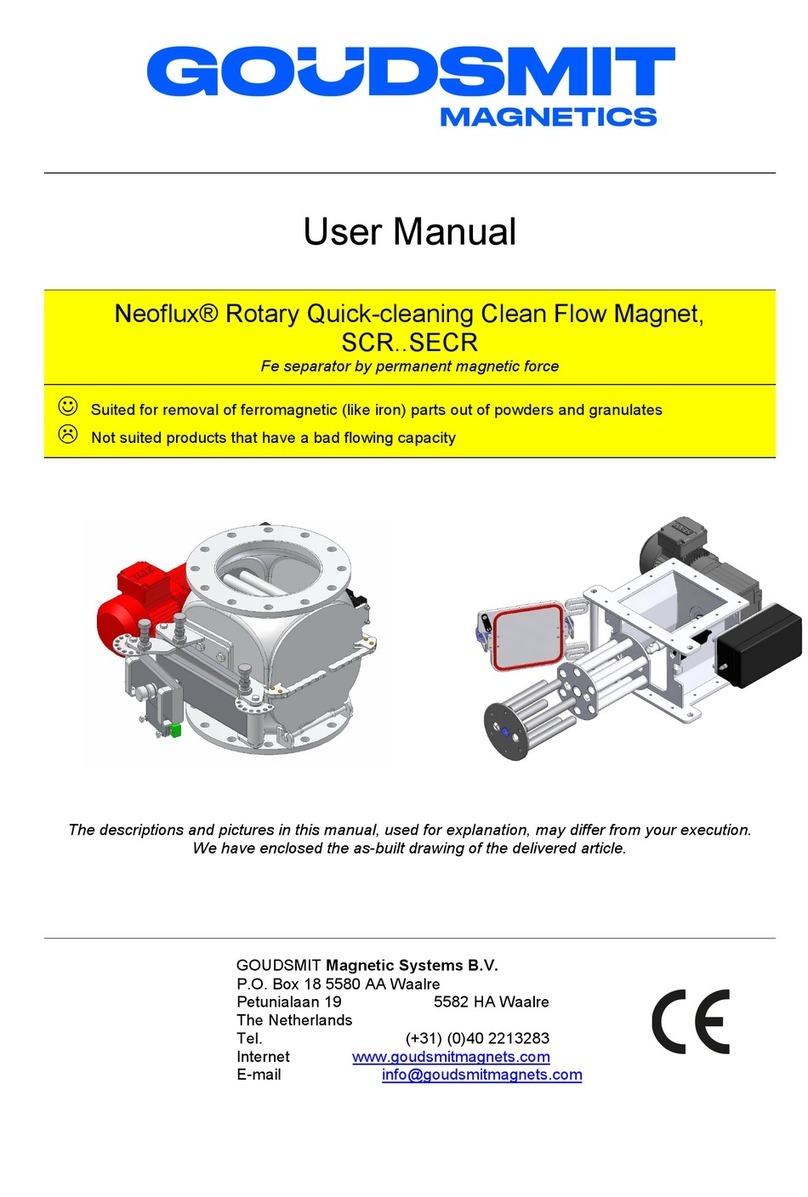

Device description..................................................................................................................................................................11

Intended use / user indications ...........................................................................................................................................11

Deliverable specials............................................................................................................................................................12

Working principle................................................................................................................................................................13

Construction .......................................................................................................................................................................14

Magnet bar cleaning ...........................................................................................................................................................15

Installation...............................................................................................................................................................................16

Transport and placing procedures ......................................................................................................................................16

Magnet bar protection.........................................................................................................................................................16

Gasket material / grounding................................................................................................................................................16

Start-up....................................................................................................................................................................................17

Maintenance............................................................................................................................................................................18

Magnet bars .......................................................................................................................................................................18

Replace magnet bars / extractor tubes .........................................................................................................................18

Cleaning & ATEX................................................................................................................................................................18

Malfunctions/Service..............................................................................................................................................................19

Spare parts..............................................................................................................................................................................20

Storage and Dismantling........................................................................................................................................................21