Assembly of the cylinder

head

1. Install the valve spring lower seat

(3) and the oil shield (4) to the valve

guide;

2. After applying a small amount of

lubricating oil to the intake valve rod (1)

and exhaust valve rod (2), install the

valve guide, install the valve outer

spring (5), the valve inner spring (6), and

the valve spring upper seat ( 7) and valve

lock clip (8);

3. Use the valve remover to depress the

valve spring, and then install the valve

lock clip into the valve spring seat;

Notice:

To prevent permanent deformation of the

valve spring, do not compress the spring too

much to fit the valve lock clip.

4. Check whether the valve lock clip is in

place;

5. Carry out the air tightness test on the

assembled cylinder head combination. If the air

tightness test of the cylinder head combination is

qualified, the next step can be performed

(assemble according to the cylinder head

composition diagram);

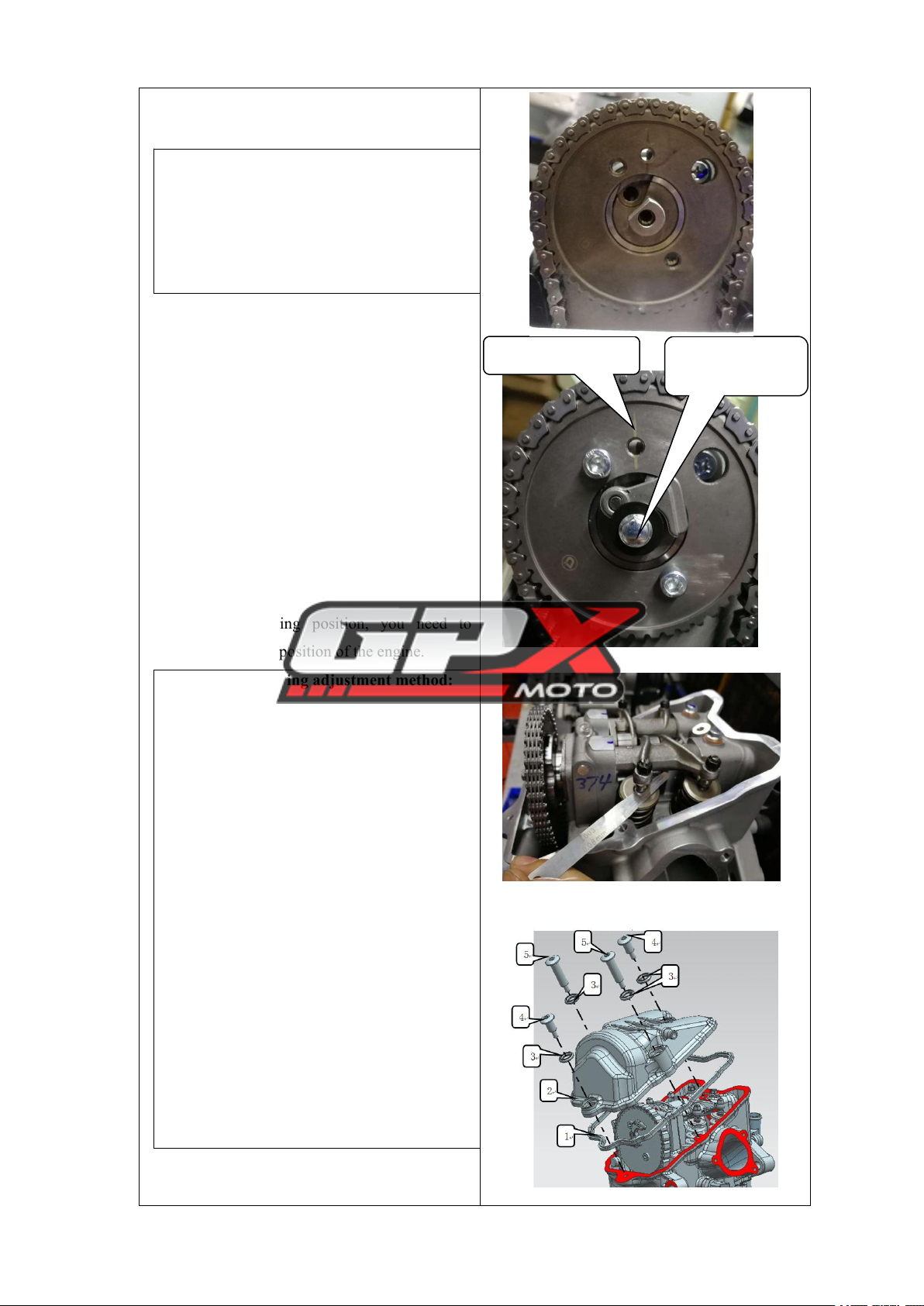

6. Take the assembled camshaft parts,

apply grease on the surface of the small

journal, assemble it at the position of the

camshaft hole of the cylinder head, take

the screw M6 ×12, insert it into the camshaft

pressure plate hole, assemble it at the designated

position of the cylinder head, and fasten;

7. Take the intake rocker arm and the

valve rocker arm shaft respectively, and

assemble them at the position of the

cylinder head intake rocker arm shaft

This side is the cutting edge of the rocker

arm shaft. When assembling the rocker arm

shaft, this side should face the top of the

cylinder head cover