3

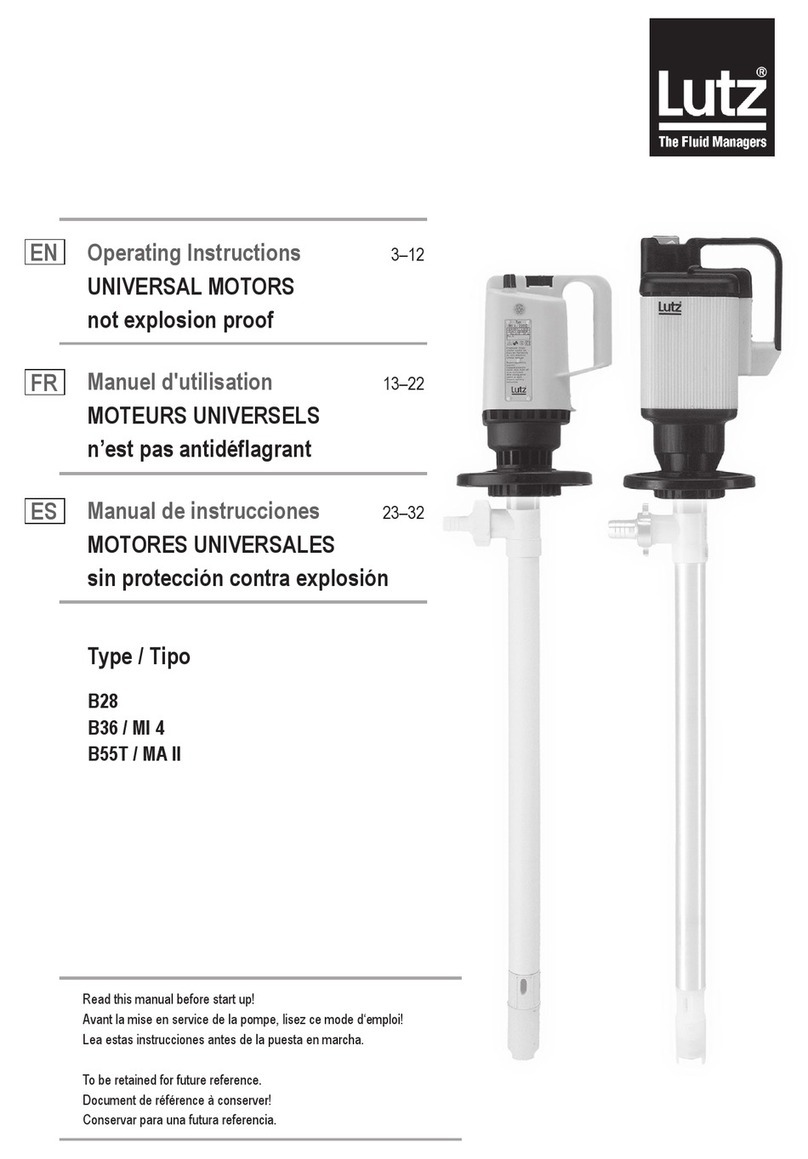

Please read these important safety instructions before commissioning!

Incorrect installation can cause serious personal injury and damage to property.

The warranty claim expires in case of non-observance of this user information with all contained notes and regulations.

In case of non-observance of these instructions, the manufacturer or supplier shall not be liable for any personal injury or property damage incurred.

SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

IMPROPER USE

This symbol indicates information about general danger.

Non-observance can mean danger to

persons and objects!

PROPER USE

This symbol indicates important information that can

ensure safe and proper use of the device.

This symbol indicates danger due to electrical energy.

Danger to persons and objects may arise if the

associated information is not observed!

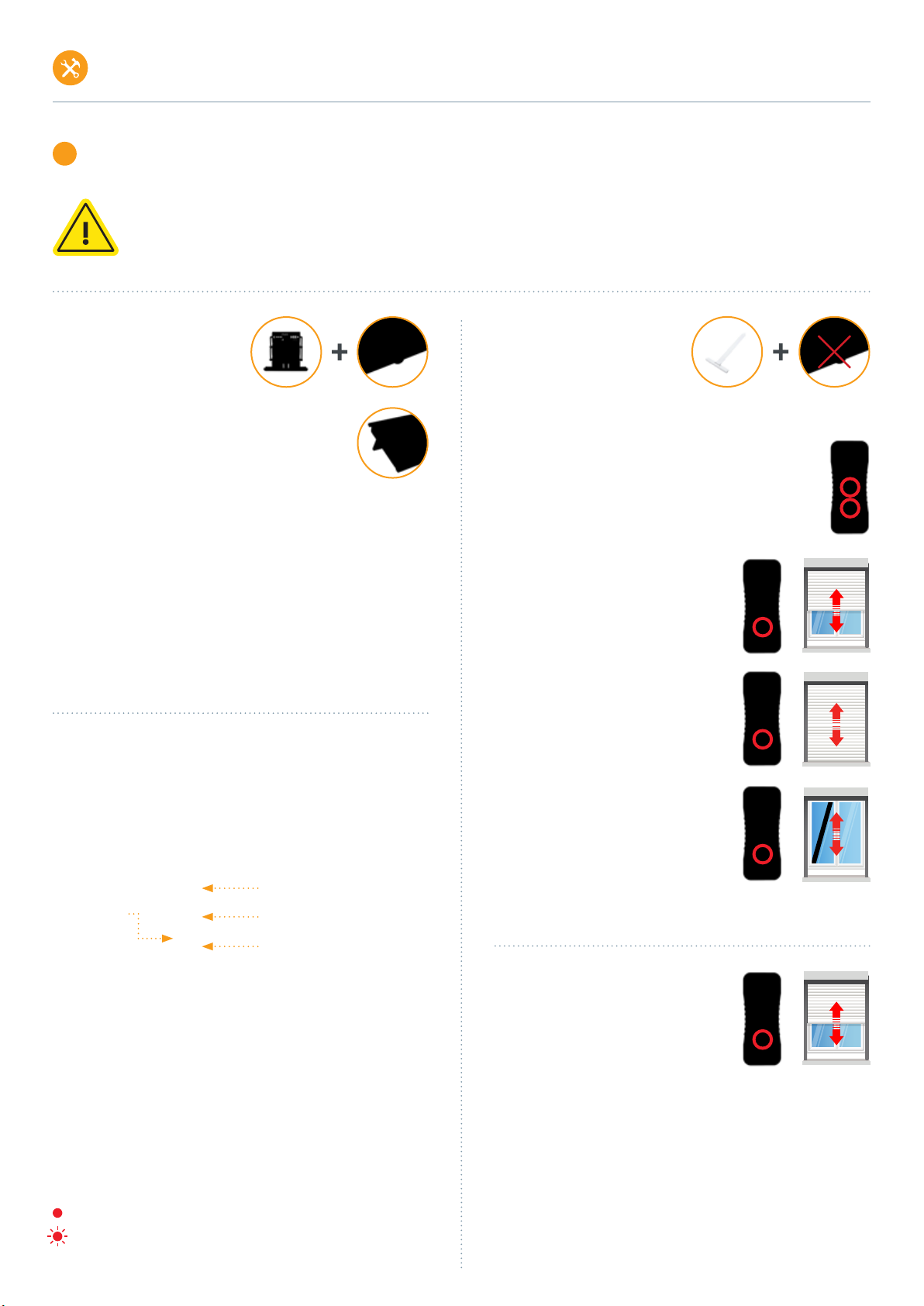

•Danger to life from electric shock when working on electrical equipment.

•The electrical connection, installation and commissioning of the receiver may only be carried out

by qualied personnel.

•The timer may only be installed and connected in a de-energized state.

•The relevant regulations and guidelines must be followed without fail, to avoid damage to persons and objects.

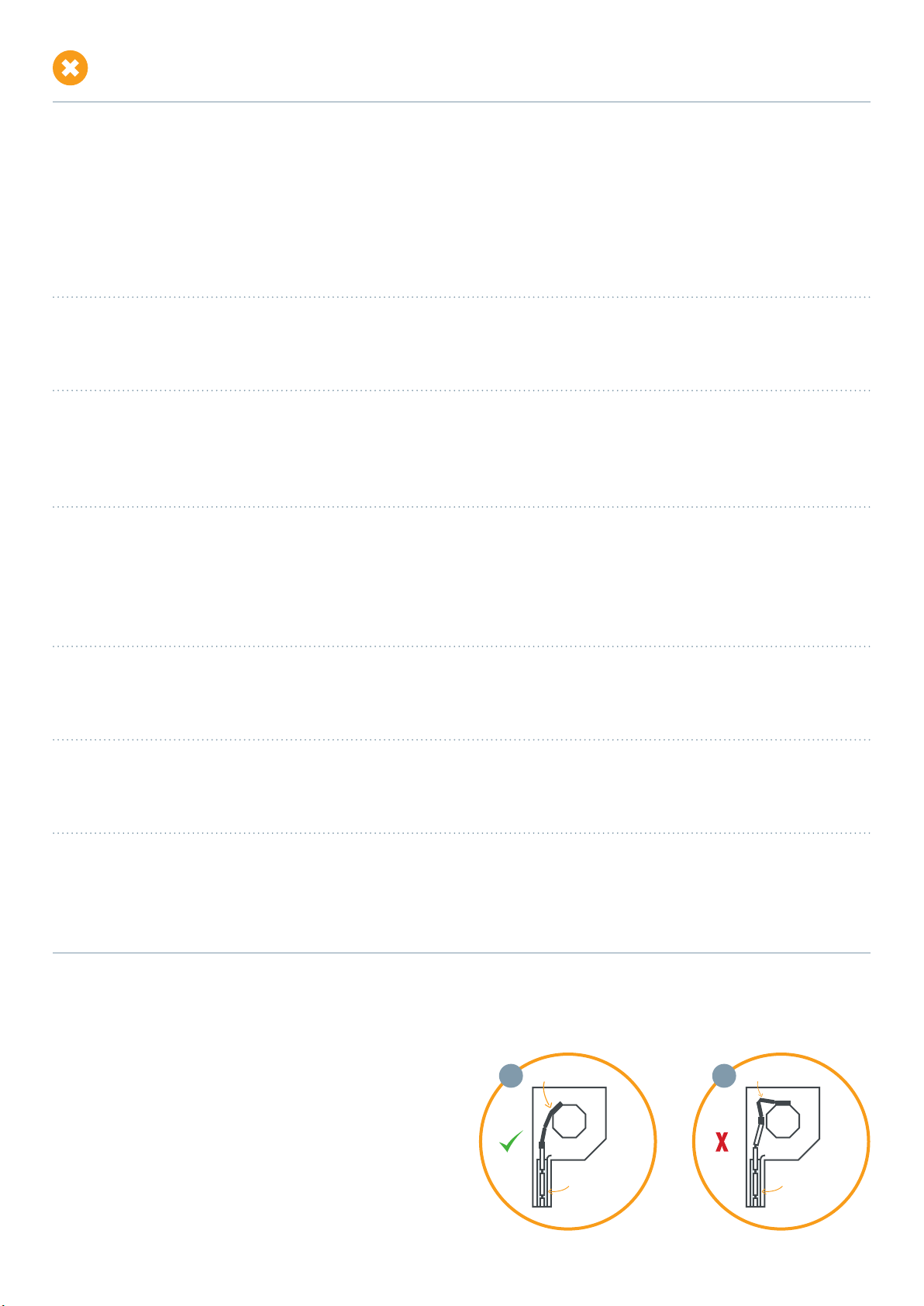

•Observe safety instructions according to EN 60 335-2-97: The power supply cable of the drives must be laid internally.

•Installation according to DIN 18073: The roller shutter box cover must be easily accessible and removable.

•Installation according to EN 60335: Only switches / pushbuttons / switching devices with a minimum contact opening

of 3 mm may be used. Furthermore the up and down direction must be interlocked against each other.

•When installing in damp rooms, observe regulations (VDE 0100, part 701 and 702).

•These drives can be connected in parallel without an isolating relay or central control.

In this case, the max. output power of the command transmitter (timer or otherwise) must be observed.

•Do not use defective devices: Never use defective equipment.

Periodically inspect the equipment for imbalance and signs of wear or damage to cables and suspension springs.

Do not use equipment if repair or rework is necessary.

There is a risk of personal injury and property damage due to electric shock or short circuit.

•Retain the instructions for future reference.

•Persons are to be instructed with the correct operation of the tubular motor.

•The roller shutter movement must be monitored in order not to endanger persons.

•Do not allow children to play with motor controls.

•Store the handheld transmitter in such a way that unintentional operation is prevented (e.g. by children playing).

•The device can be used by children aged 8 years and above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge, if they have been given supervision and instruction concerning use

of the appliance in a safe way and are aware of the hazards involved.

•Children are not allowed to play with the equipment.

•If the power supply cord of this device is damaged, it must be replaced by the manufacturer or its customer service

or a similarly qualied person to prevent hazards.

•Use tubular motors only for automating shutters.

•Only use original components and original accessories from the manufacturer.

•The mains connection cable of the drives must be laid internally in the empty conduit up to the junction box.

The local electrical regulations must be observed.

•For the electrical connection of the tubular motors, a 230 V / 50 Hz

power connection with fuse must be available at the installation site.

3T-MOTORS Tubular motors | Safety instructions