iii

GraceSenseTM Hot Spot Monitor

Figures

Figure 1: HSM Modules ................................................................................................................................ 6

Figure 2: Fiber-Optic Probe .......................................................................................................................... 6

Figure 3: Ring-Style Mounting Fixture .......................................................................................................... 6

Figure 4: HSM System Overview .................................................................................................................. 8

Figure 5: HSM Module Overall Views ........................................................................................................ 10

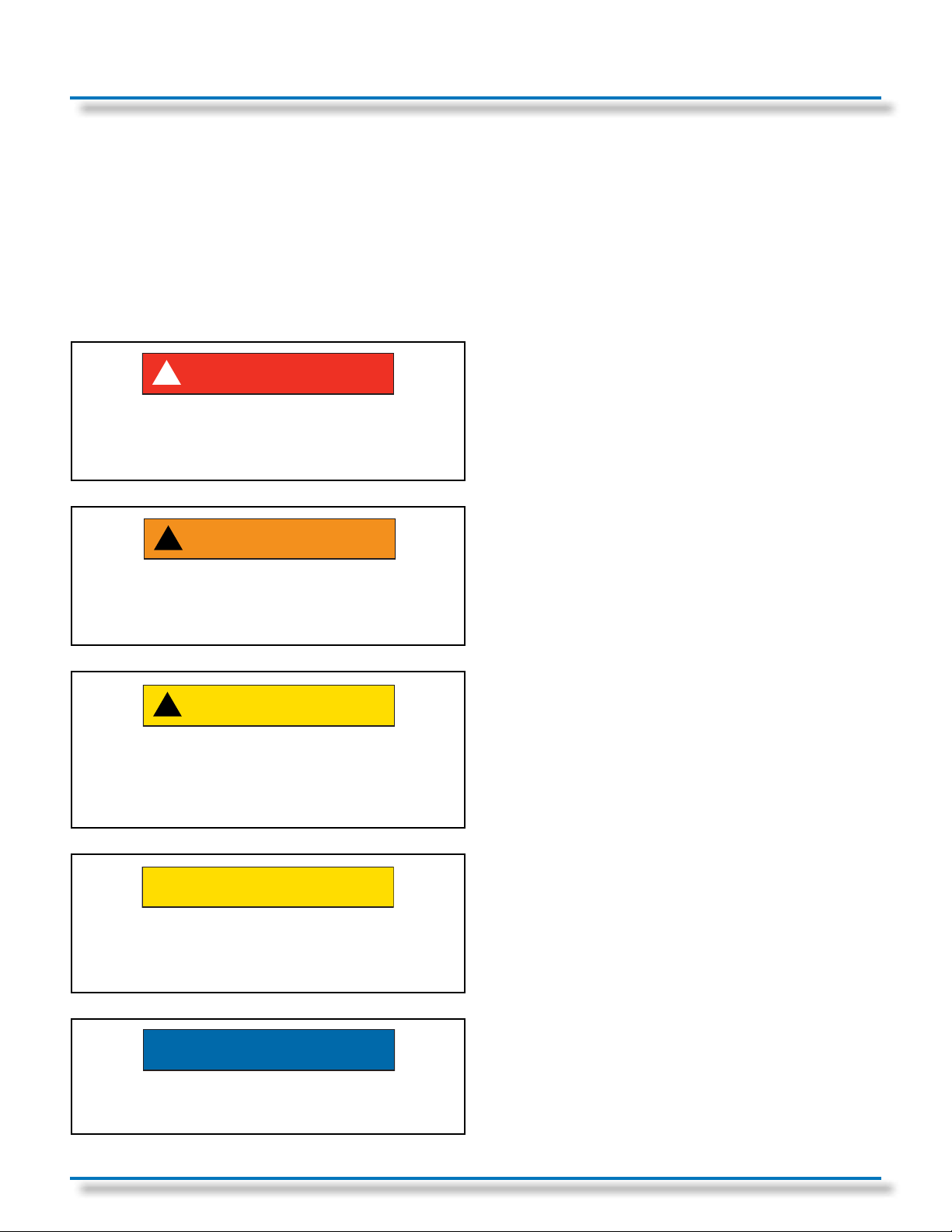

Figure 6: Indicator LED's .............................................................................................................................11

Figure 7: HSM Status LED's ........................................................................................................................11

Figure 8: Interface Ports ............................................................................................................................. 12

Figure 9: Fiber-Optic Probe with Probe Lock .............................................................................................. 13

Figure 10: Tyco/Amp Ring Style Lugs ........................................................................................................ 13

Figure 11: Installation Sequence of Lug with Standard Washers ............................................................... 14

Figure 12: Installation Sequence of Lug with Belleville Washers ............................................................... 14

Figure 13: Mounting Lug ............................................................................................................................. 14

Figure 14: Secure Probe by Tightening Allen Key ...................................................................................... 14

Figure 15: Correctly Installed Probe and Lug ............................................................................................. 15

Figure 16: Fiber Limitations ........................................................................................................................ 15

Figure 17: Electrical Tape Installation ......................................................................................................... 16

Figure 18: Tie-Wrap Being Secured Over Fiber ......................................................................................... 16

Figure 19: Completed Fiber Installation ...................................................................................................... 16

Figure 20: Safe Dielectric Routing Practices .............................................................................................. 17

Figure 21: DIN Rail Clearances .................................................................................................................. 18

Figure 22: Installing HSM Module onto DIN Rail ........................................................................................ 18

Figure 23: Removing HSM Module from DIN Rail ...................................................................................... 18

Figure 24: Terminal Connectors of HSM Module ....................................................................................... 18

Figure 25: Typical Grounding via Grounded Din Rail ................................................................................. 20

Figure 26: Typical Grounding via PE Terminal ............................................................................................ 20

Figure 27: Typical Serial Topology for MODBUS RTU ................................................................................ 21

Figure 28: Star Topology ............................................................................................................................. 21

Figure 29: Fiber Trimmer ............................................................................................................................ 22

Figure 30: Fiber Trimmed ........................................................................................................................... 22

Figure 31: Fiber Installation ........................................................................................................................ 22

Figure 32: Web Interface Navigation .......................................................................................................... 24

Figure 33: LCD Interface Navigation .......................................................................................................... 24

Figure 34: LCD Menu and Navigation ........................................................................................................ 25

Figure 35: Credential Validation Screen ..................................................................................................... 26

Figure 36: Network Configuration Web Page ............................................................................................. 26

Figure 37: MODBUS Configuration Web page ........................................................................................... 27

Figure 38: Device Configuration Web page ................................................................................................ 27