Registering the Meter

313046T 7

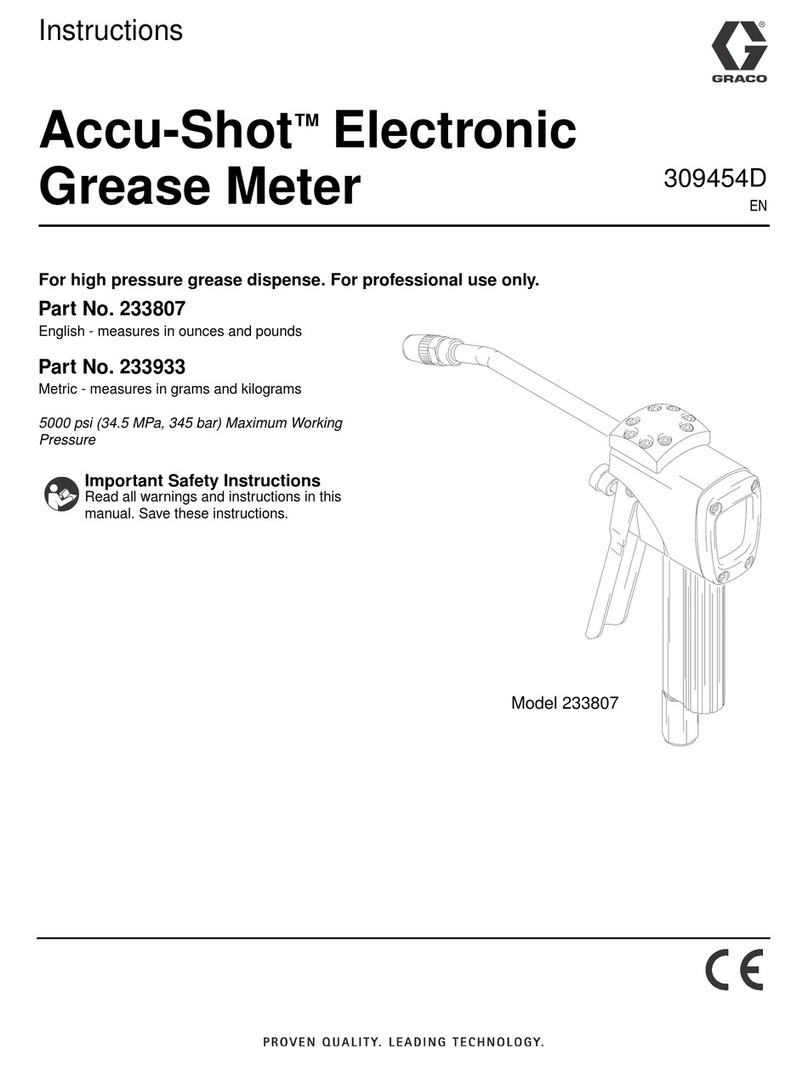

REGISTER Screen

A. NETWORK ID: The unique Radio Frequency (RF)

assigned to components of the same operating system

in a specific facility. The unique NETWORK ID assigned

to the facility, prevents RF interference from other Matrix

Systems operating in the vicinity, at other locations.

There are 8 NETWORK ID’s available.

To setup a meter to receive the correct NETWORK ID

RF signal, use the UP or DOWN ARROWS to scroll, one

number at a time, through the NETWORK ID numbers

(1-8). When the correct NETWORK ID number assigned

to your facility is displayed in the field/box, press center

ENTER button on meter’s keypad to lock in the choice.

B. TRANS ID: The unique RF frequency assigned to a

specific transceiver in the operating system. Each

transceiver in the system has its own TRANS(ciever) ID

number assigned to it. An operating system can have

more than one transceiver. There are 8 TRANS ID’s

available.

To set up a meter to receive the correct TRANS ID RF

Signal, use the UP or DOWN ARROWS to scroll, one

number at a time, through the TRANS ID numbers (1-8).

When the number assigned to the transceiver you are

using displays in the field/box, press center ENTER

button on meter’s keypad to lock in the choice.

C. REGISTER /field: Sends message to Matrix PC

Software to register the meter with the operating

system.

Use the LEFT or RIGHT ARROWS to move the cursor

over the REGISTER field/box on the display. Then press

center, ENTER button on meter’s keypad, to confirm the

selection.

D. WRENCH Icon: Returns user to Main Utility Screen.

Use the LEFT or RIGHT ARROWS to move the cursor

over the WRENCH Icon on the display. Then press

center, ENTER button on meter’s keypad, to confirm the

selection.

E. SERIAL Number: Unique meter ID.

Registering Meter with Matrix PC Software

1. The screen displays the NETWORK ID (A) and

TRANS(ceiver) ID (B) (FIG. 5) currently assigned to

the meter.

2. If the ID’s in both fields are correct and you do not

need to make any changes, use LEFT or RIGHT

ARROWS to move cursor over REGISTER (C).

Press center ENTER button on meter’s keypad. The

meter resets to it’s initial screen.

OR . . .

If the NETWORK ID or TRANS ID information

shown on the display is NOT correct:

a. Use LEFT or RIGHT ARROWS to move cursor

to NETWORK ID field and/or TRANS ID field.

b. When field you want to modify is selected, use

UP or DOWN ARROWS to scroll forward or

backward through the available NETWORK ID

or TRANS ID numbers.

c. When correct ID number displays, press center

ENTER button on meter’s keypad to confirm

your choice. If necessary, use LEFT or RIGHT

ARROWS to move cursor to the next field and

repeat this procedure.

d. When both the NETWORK ID and TRANS ID

fields display the correct information, use LEFT

or RIGHT ARROWS to move cursor over REG-

ISTER. Press center ENTER button on the

meter’s keypad to complete meter registration.

FIG. 5

REGISTER

NETWORK ID 8 TRANS ID 6

REGISTERREGISTER

123F456A