2 3A8560C

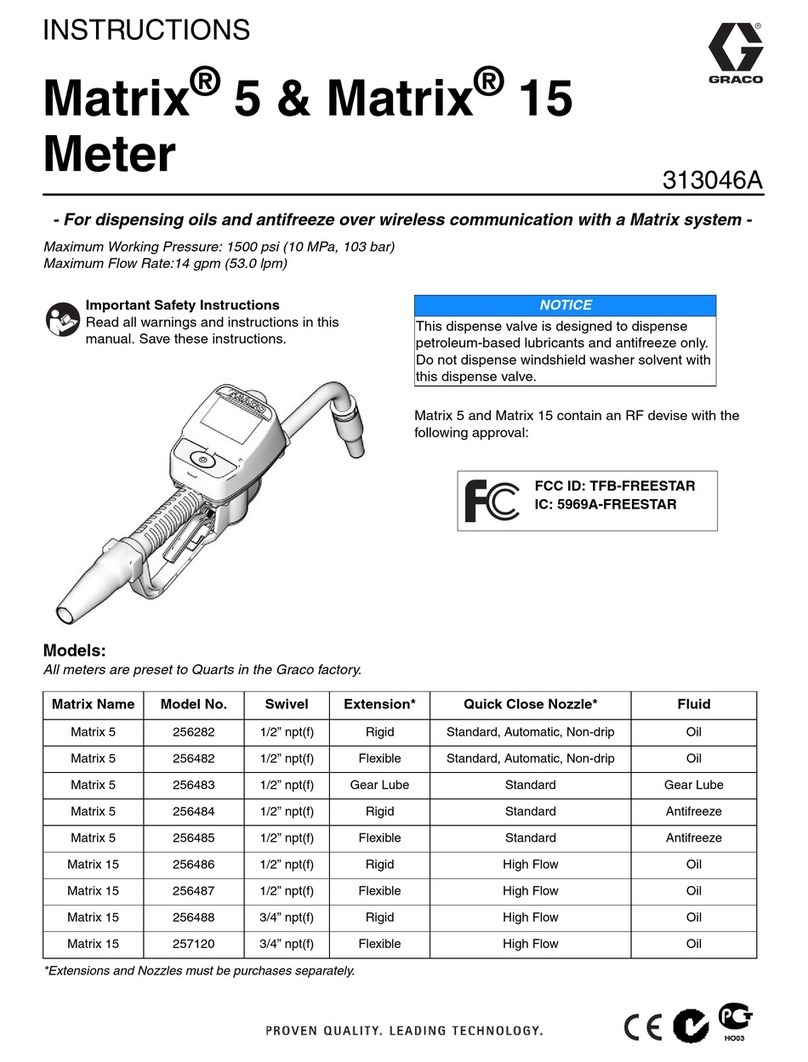

Models

Part No. Model Inlet Thread Fluid Extension Maximum Working Pressure

25U085 PM8 1/2 in. NPT Anti-freeze Rigid 200 psi (1.4 MPa, 14.0 bar)

25U086 PM8 1/2 in. NPT Anti-freeze Flex 200 psi (1.4 MPa, 14.0 bar)

25U087 PM8 1/2 in. BSPP Anti-freeze Rigid 200 psi (1.4 MPa, 14.0 bar)

25U088 PM8 1/2 in. BSPP Anti-freeze Flex 200 psi (1.4 MPa, 14.0 bar)

25U089 PM8 1/2 in. BSPT Anti-freeze Rigid 200 psi (1.4 MPa, 14.0 bar)

25U090 PM8 1/2 in. BSPT Anti-freeze Flex 200 psi (1.38 MPa, 13.8 bar)

273156 PM8 1/2 in. NPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273157 PM8 1/2 in. NPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273158 PM8 1/2 in. NPT Gear lubes Gear lube 1500 psi (10.3 MPa, 103 bar)

273159 PM8 1/2 in. BSPP Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273160 PM8 1/2 in. BSPP Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273161 PM8 1/2 in. BSPP Gear lubes Gear lube 1500 psi (10.3 MPa, 103 bar)

273162 PM8 1/2 in. BSPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273163 PM8 1/2 in. BSPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273164 PM8 1/2 in. BSPT Gear lubes Gear lube 1500 psi (10.3 MPa, 103 bar)

273165 PM20 1/2 in. NPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273166 PM20 1/2 in. NPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273167 PM20 3/4 in. NPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273168 PM20 3/4 in. NPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273169 PM20 1/2 in. BSPP Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273170 PM20 1/2 in. BSPP Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273171 PM20 3/4 in. BSPP Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273172 PM20 3/4 in. BSPP Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273173 PM20 1/2 in. BSPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273174 PM20 1/2 in. BSPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)

273175 PM20 3/4 in. BSPT Petroleum based oils Rigid 1500 psi (10.3 MPa, 103 bar)

273176 PM20 3/4 in. BSPT Petroleum based oils Flex 1500 psi (10.3 MPa, 103 bar)