INJECTION HAZARD

Spray

from the gun, leaks or ruptured components can inject fluid into your body and cause ex

-

tremely serious injury

, including the need for amputation. Fluid splashed in the eyes or on the skin

can also cause serious injury

.

Fluid injected into the skin is a serious injury

. The injury may look like just a cut, but it is a serious

injury

. Get immediate medical attention.

Do not point the gun at anyone or at any part of the body

.

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body

, glove or rag.

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun dif

fuser operation weekly

. Refer to the gun manual.

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

Follow the

Pressure Relief Procedure

on page 12 if the spray tip clogs and before cleaning,

checking or servicing the equipment.

T

ighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

. Replace worn or damaged parts immediately

. Do

not repair high pressure couplings; you must replace the entire hose.

Fluid hoses must have spring guards on both ends, to help protect them from rupture caused by

kinks or bends near the couplings.

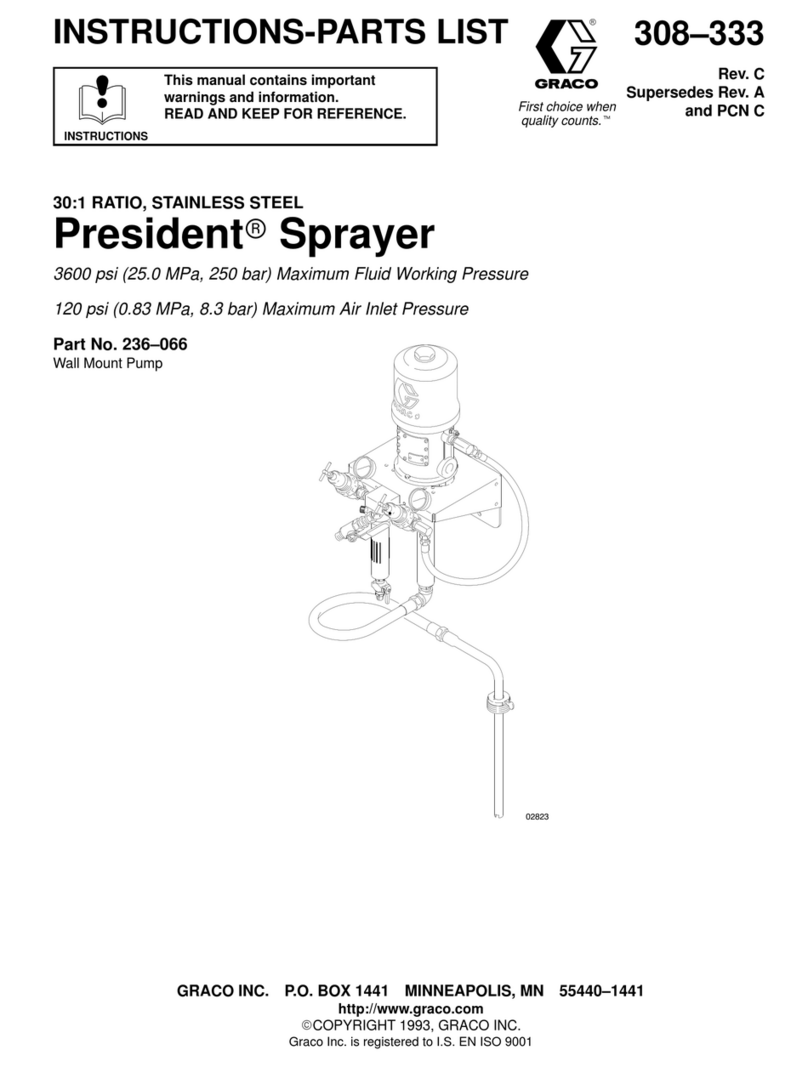

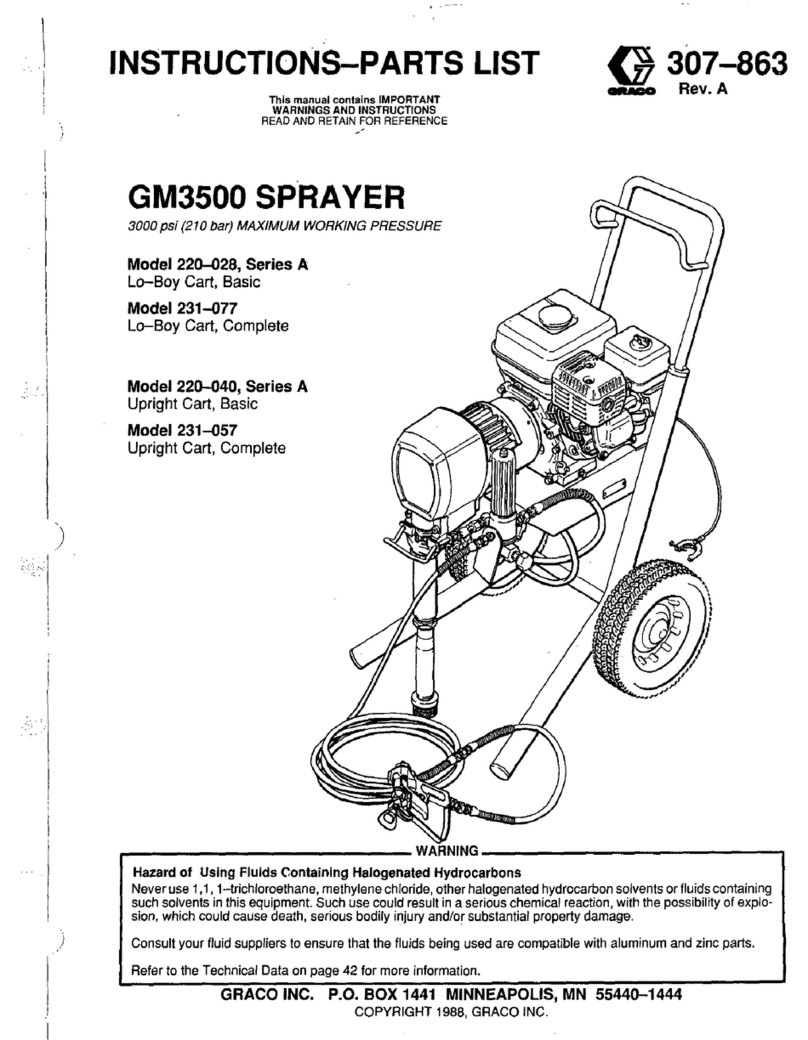

WARNING

WARNING

Liquids

can be injected into the body by high

pressure airless spray

or

leaks – especially hose leaks.

Keep

body clear of the nozzle. Never stop leaks with any part of the

body.

Drain all pressure before removing parts.A

void accidental trig

-

gering

of gun by always setting safety latch when not spraying.

Never spray without a tip guard.

In case of accidental skin injection, seek immediate

“Surgical

T

reatment”.

Failure to follow this warning can result in amputation or serious

injury.

FIRE

AND

EXPLOSION HAZARD

SKIN INJECTION

HAZARD

READ AND UNDERSTAND ALL LABELS AND INSTRUCTION MANUALS BEFORE USE

Spray

painting,

flushing or cleaning equipment with flammable liq

-

uids

in confined areas can result in fire or explosion.

Use

outdoors or in extremely well ventilated areas. Ground equip

-

ment,

hoses, containers and objects being sprayed.

Avoid

all ignition sources such as

static electricity from plastic drop

cloths,

open flames

such as pilot lights, hot objects such as ciga

-

rettes,

arcs from

connecting or disconnecting power cords or turn

-

ing

light switches on and off.

Failure

to follow this warning can result in death or serious injury

.

NOTE: This

is an example of the DANGER label on your sprayer

. This label is available in other languages,

free of charge.