2309860

EQUIPMENT MISUSE HAZARD

Misuse can cause the equipment to rupture or

malfunction and result in serious injury.

To help prevent injury

Do not modify or use parts not designed for

this equipment.

Do not use 1,1,1–trichloroethane, methylene

chloride, other halogenated hydrocarbon sol-

vents or fluids containing such solvents in this or

any other pressurized aluminum equipment.

Such use could result in a chemical reaction,

with the possibility of explosion.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause

serious injury or death if splashed in eyes

eyes or on skin, inhaled, or swallowed.

To help prevent injury or death from

toxic fluids

Know specific hazards of fluid you are using; store hazardous fluid

in approved container; dispose of hazardous fluid according to all

local, state, and national guidelines.

Always wear protective eyewear, gloves, clothing, and respirator as

recommended by fluid and solvent manufacturer.

SKIN INJECTION HAZARD

If high-pressure fluid pierces skin, the injury might

look like “just a cut” but is a serious wound. Get

immediate surgical treatment.

To help prevent injection

Always lock gun trigger safety latch when not

spraying.

Always shut off power and relieve pressure when

you stop spraying and before you service or clean

sprayer, remove parts, or repair leaks. See

Pressure Relief Procedure, page 5.

Do not allow children to use this equipment.

Keep clear of tip and/or roller frame. Never point at

yourself or anyone else.

pressure

FLUID SPLASHBACK HAZARD

To avoid splashing fluid when spraying

into pail, always aim at inside wall of pail.

Make sure gun is assembled with correct

gasket for fluid being sprayed.

FIRE AND EXPLOSION HAZARD

A Fire and explosion hazard exists any time you

spray or flush flammable fluids.

To help prevent fire or explosion when spraying

flammable fluids

Do not use plastic drop cloths when

spraying or flushing flammable fluids.

Avoid all ignition sources, such as pilot lights,

cigarettes, and plastic drop cloths (static arc

hazard). Do not plug in or unplug power cords or

turn lights on or off in spray area.

Tape wall switches to prevent them from being

turned off or on.

Do not smoke in spray area.

Use only Graco airless paint hoses.

Use outdoors or in a well-ventilated area.

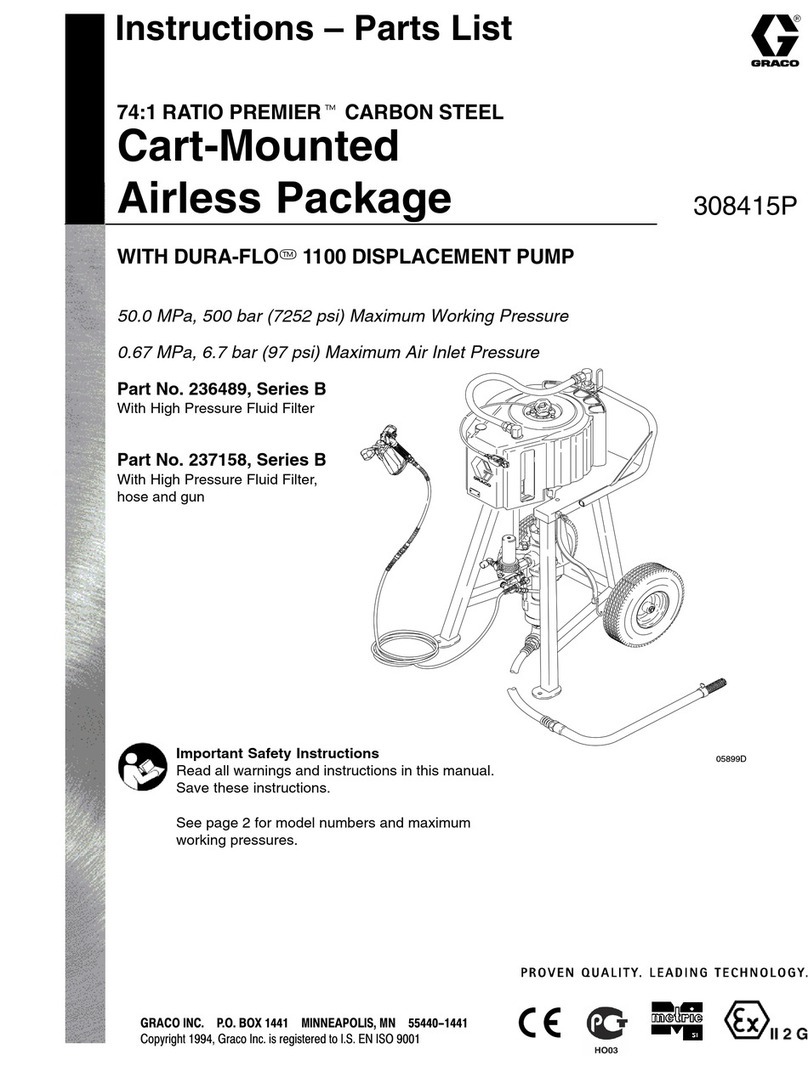

PRESSURIZED EQUIPMENT HAZARD

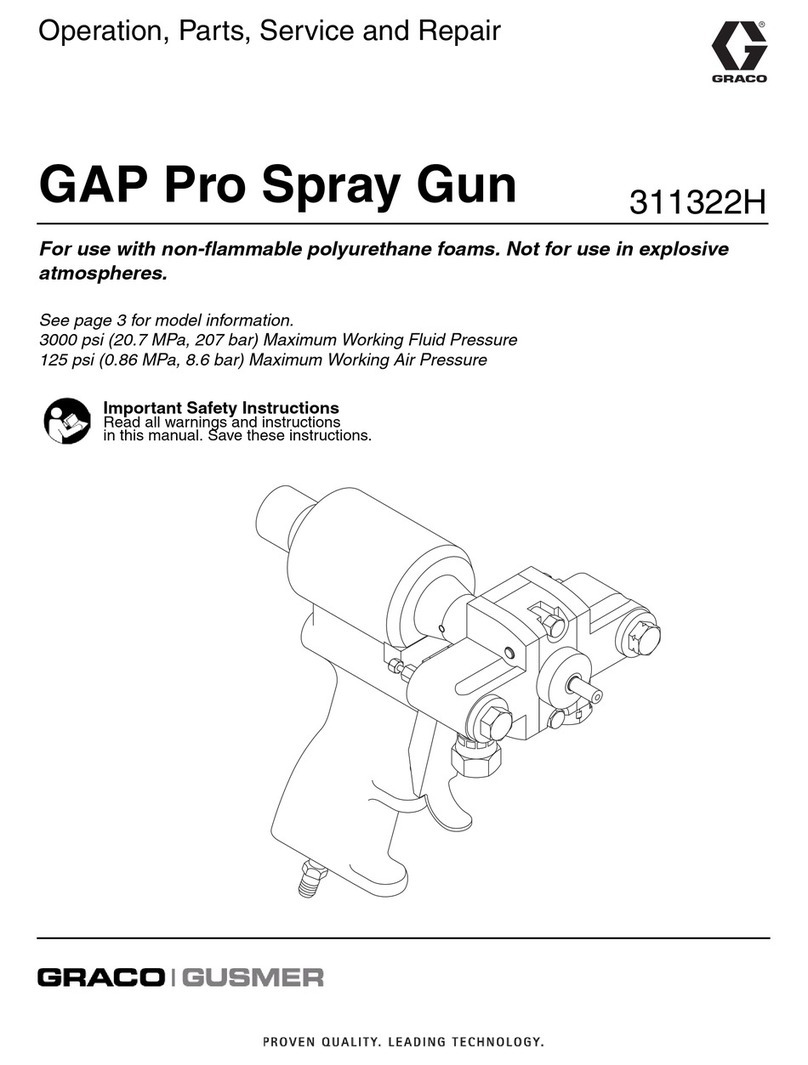

This sprayer is capable of

producing up to 3000 psi (20.7 MPa, 207 bar)

maximum working pressure. To avoid

component rupture and injury, do not operate sprayer

with components rated less than pressure of sprayer.

Sprayer is equipped with a pressure drain that automatically relieves

overpressure in the event of a fault condition. This automatic pressure

relief may cause splashing of fluid. Correct fault before you resume

spraying.

NOTE: Inadequate flushing and/or dried paint in drain

system may prevent proper overpressure relief.

SHOCK HAZARD

Failure to observe the following electrical hazards

could result in serious injury, including burns or

electrocution.

To help prevent harmful electric shock

Use only grounded electrical outlets.

Only use 3-wire extension cords.

Make sure ground prongs are intact on sprayer and extension cords.

Keep electrical connections and inside of shroud dry.

Avoid contact with power lines.

Only use Graco airless paint hoses.

Unplug sprayer before servicing.

PINCH HAZARD

Do not touch moving parts with fingers or tools while

testing or repairing. Shut off and unplug sprayer when

inspection is complete. Install all covers, gaskets,

screws and washers before operating sprayer.

Do not operate equipment under the influence of alcohol or while taking

medication that impairs your senses or reactions.

ALCOHOL AND DRUG HAZARD