Graco 330GS User manual

Other Graco Paint Sprayer manuals

Graco

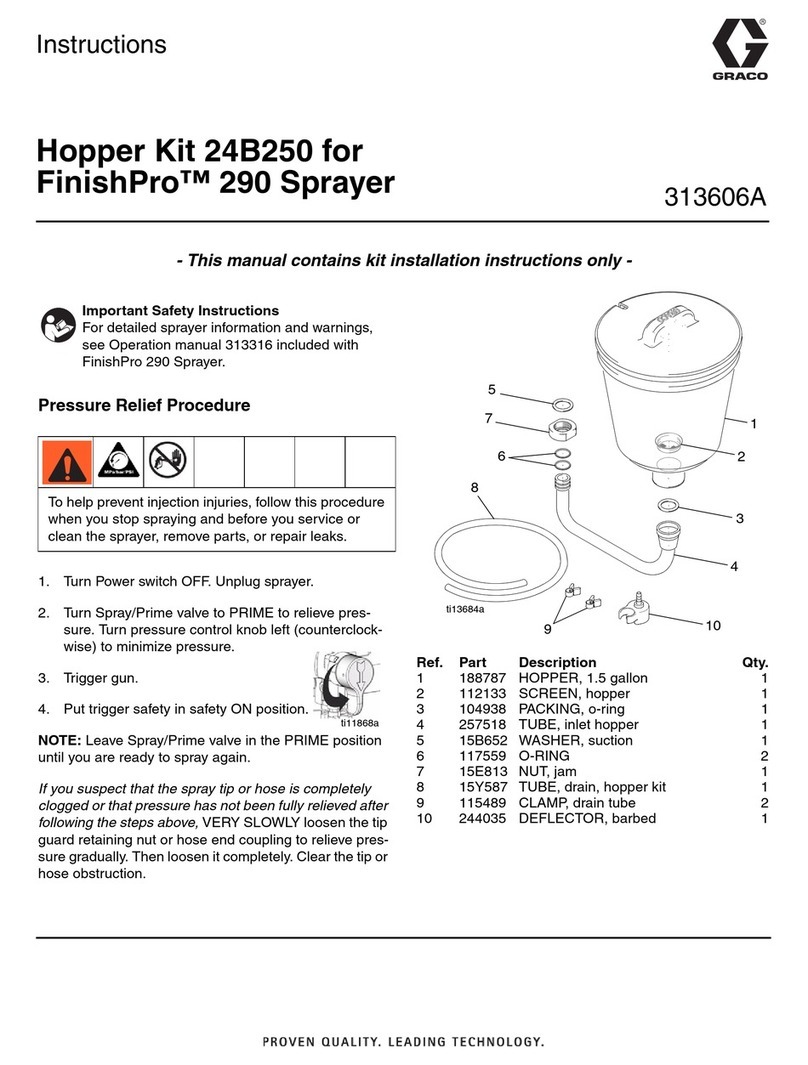

Graco Hopper 24B250 User manual

Graco

Graco 695 Premium Hi Guide

Graco

Graco AIRLESSCO SP400 Hi Boy Operating instructions

Graco

Graco 245924 Guide

Graco

Graco 2300 Hi-Boy Guide

Graco

Graco SaniSpray HP 130 Use and care manual

Graco

Graco 288629 User manual

Graco

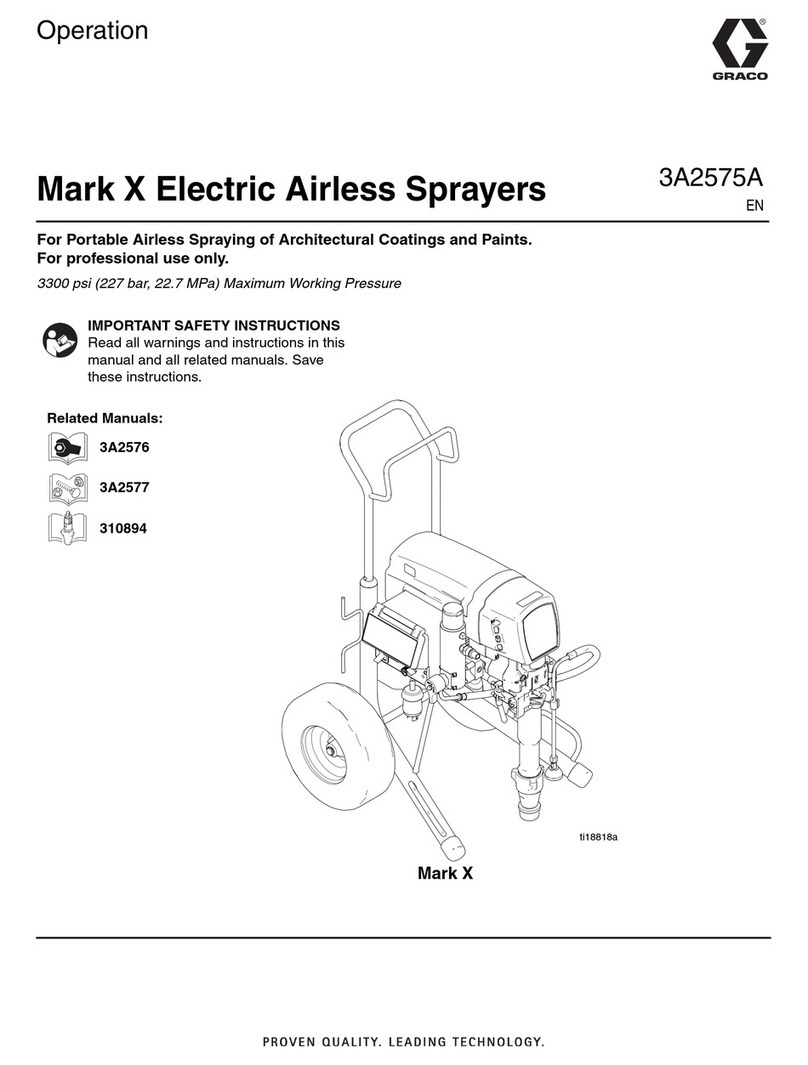

Graco Mark X User manual

Graco

Graco 288046 Parts list manual

Graco

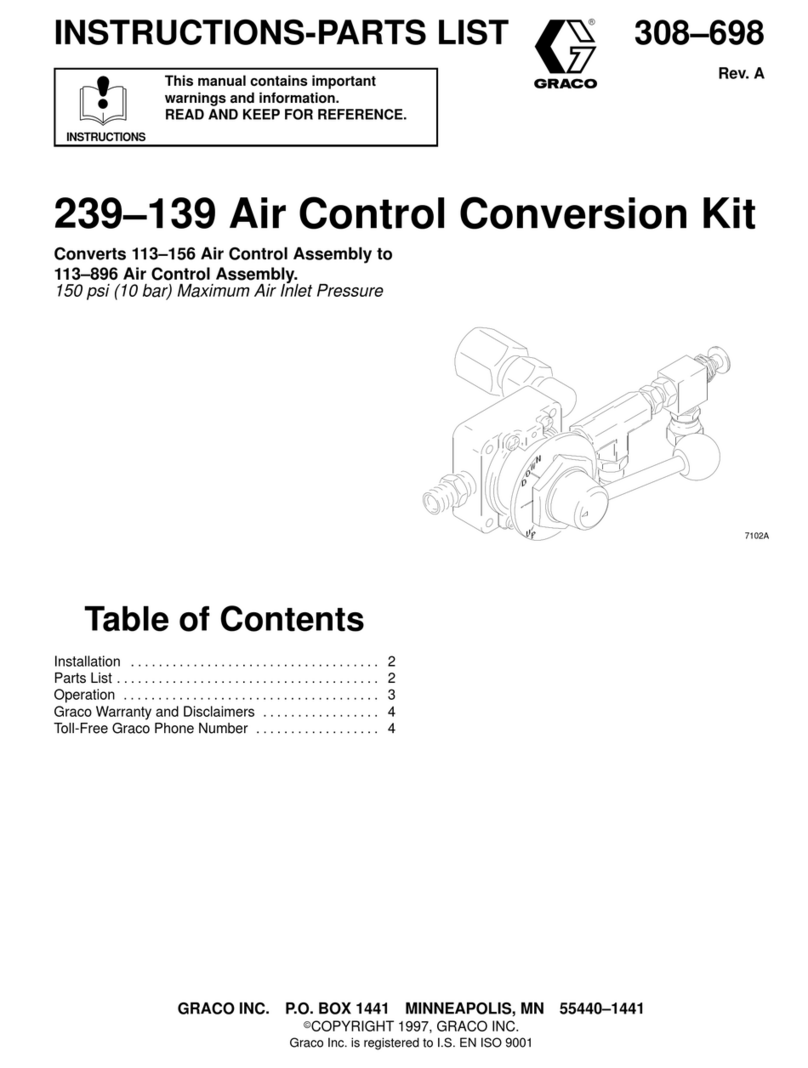

Graco 239-139 Operation manual

Graco

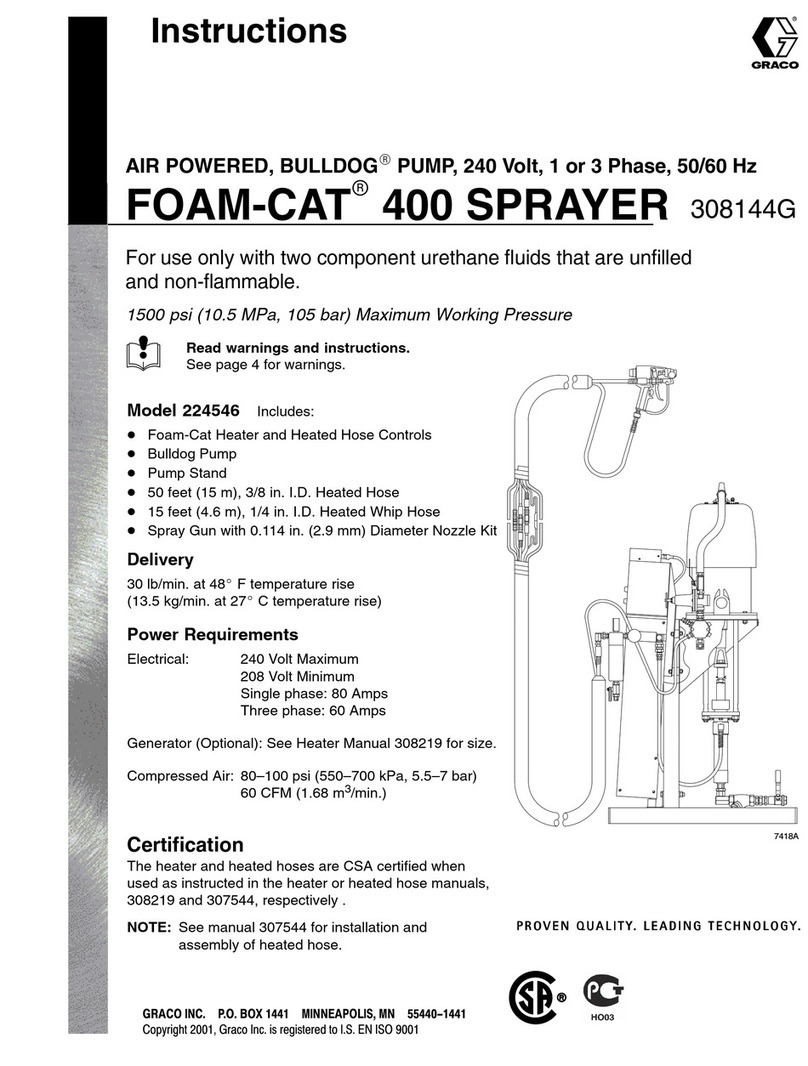

Graco FOAM-CAT 400 SPRAYER User manual

Graco

Graco SaniSpray HP ProPack 25T780 Use and care manual

Graco

Graco GX-7A User manual

Graco

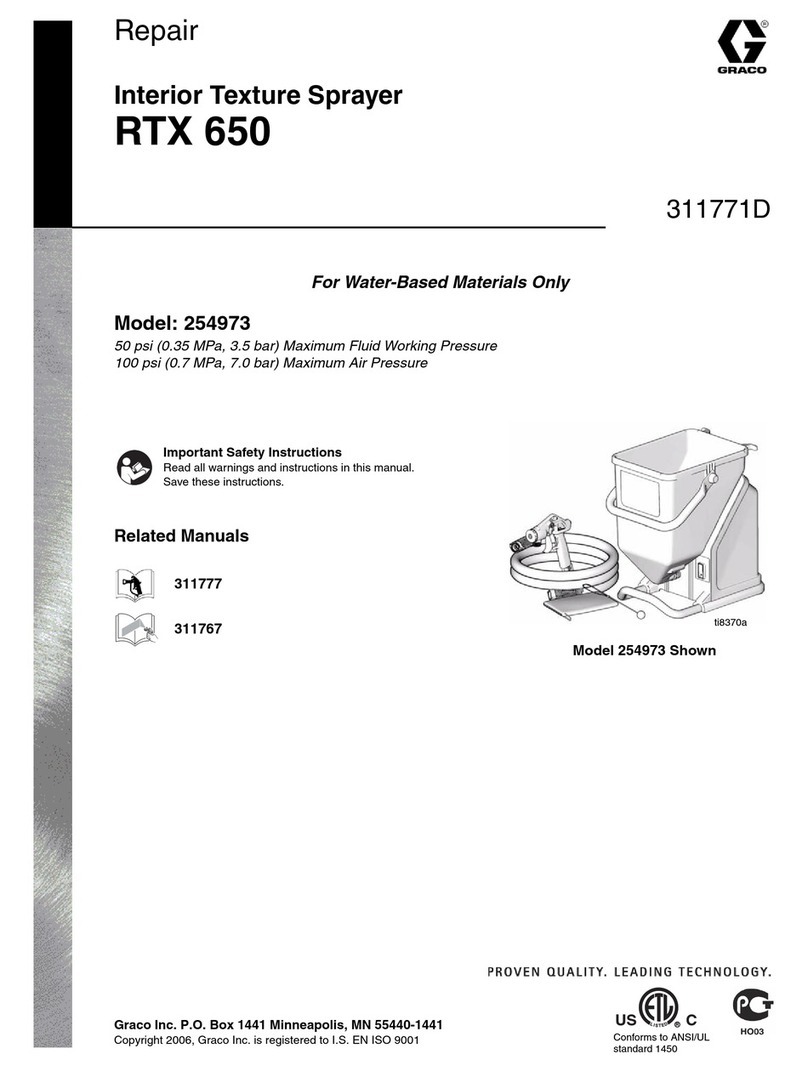

Graco RTX-650 Programming manual

Graco

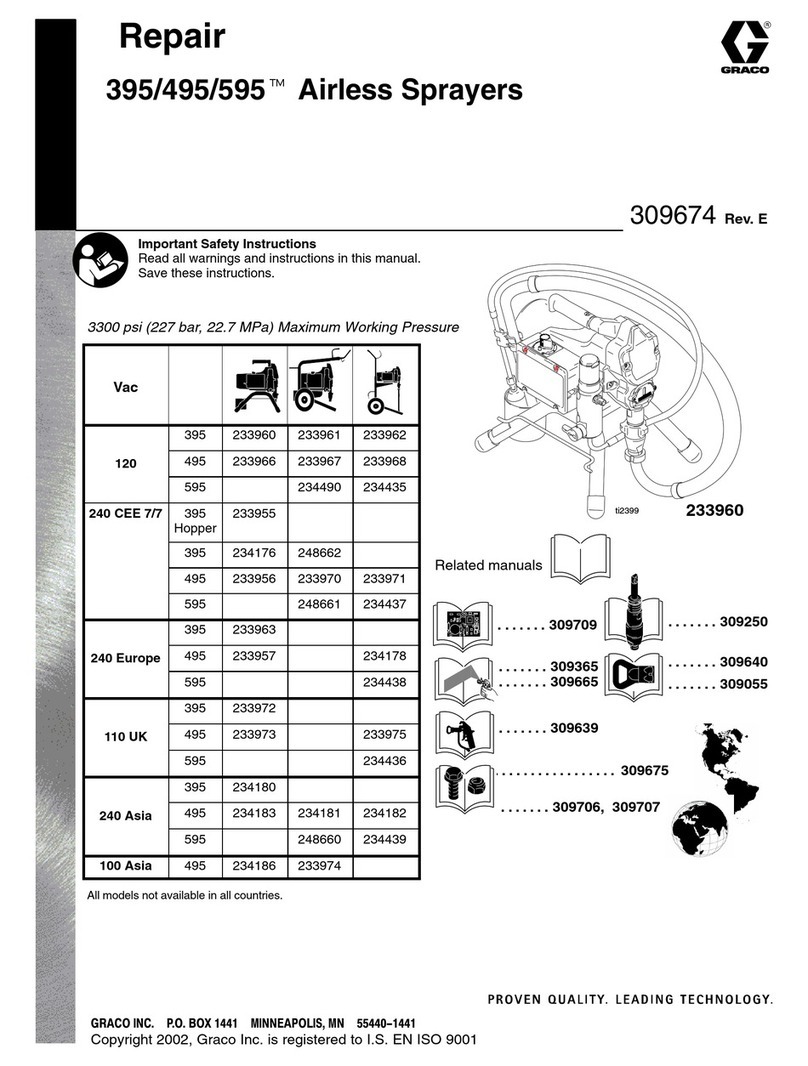

Graco 395 233960 Operating instructions

Graco

Graco RTX-650 Operating instructions

Graco

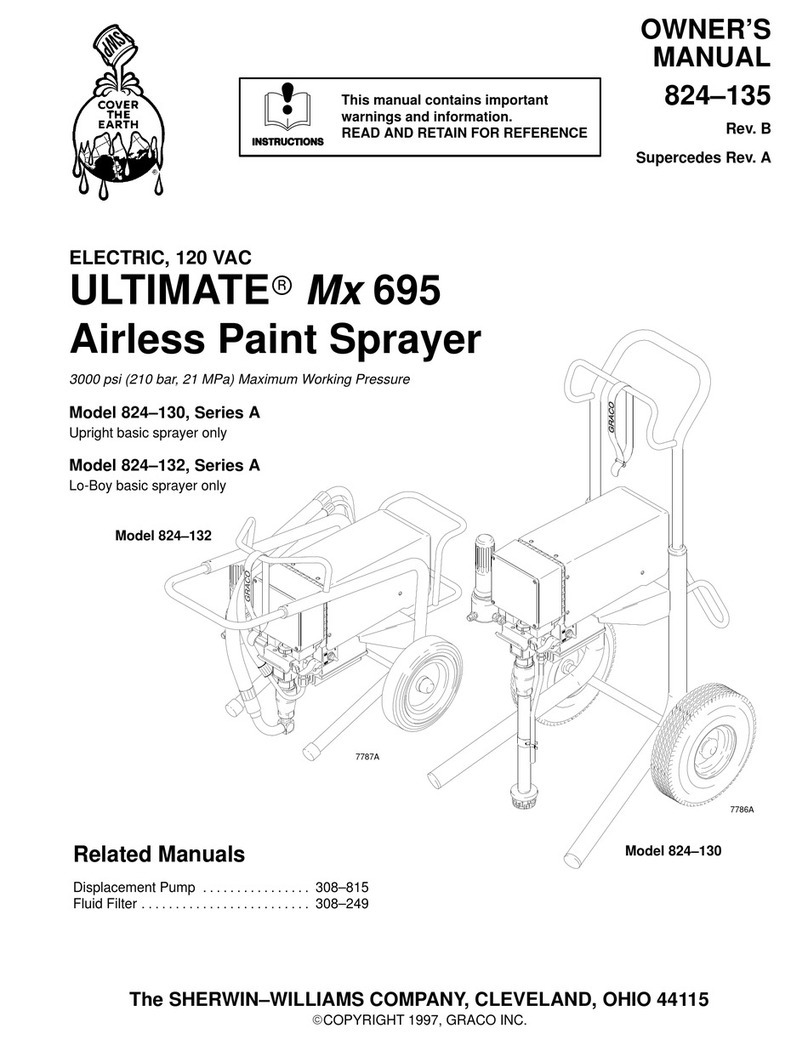

Graco Series A User manual

Graco

Graco 3A4803A Guide

Graco

Graco 824-130 User manual

Graco

Graco GM 3500 Operation manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual