6 310562

Setup

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 10.

Site Preparation

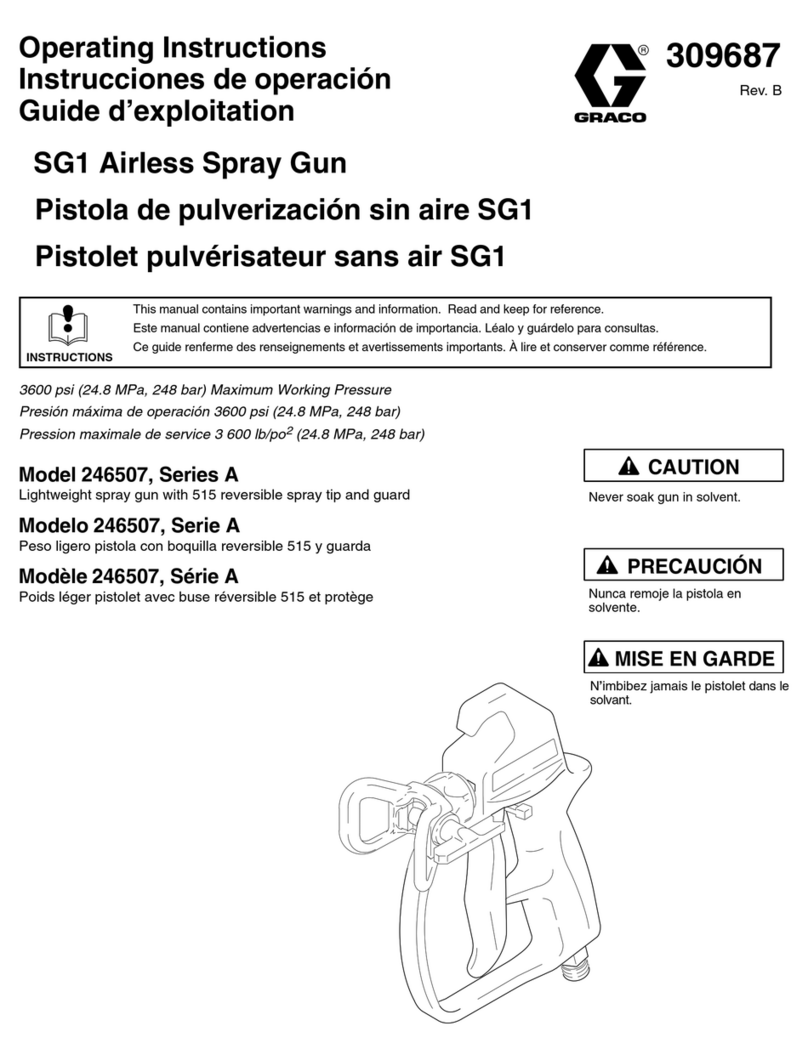

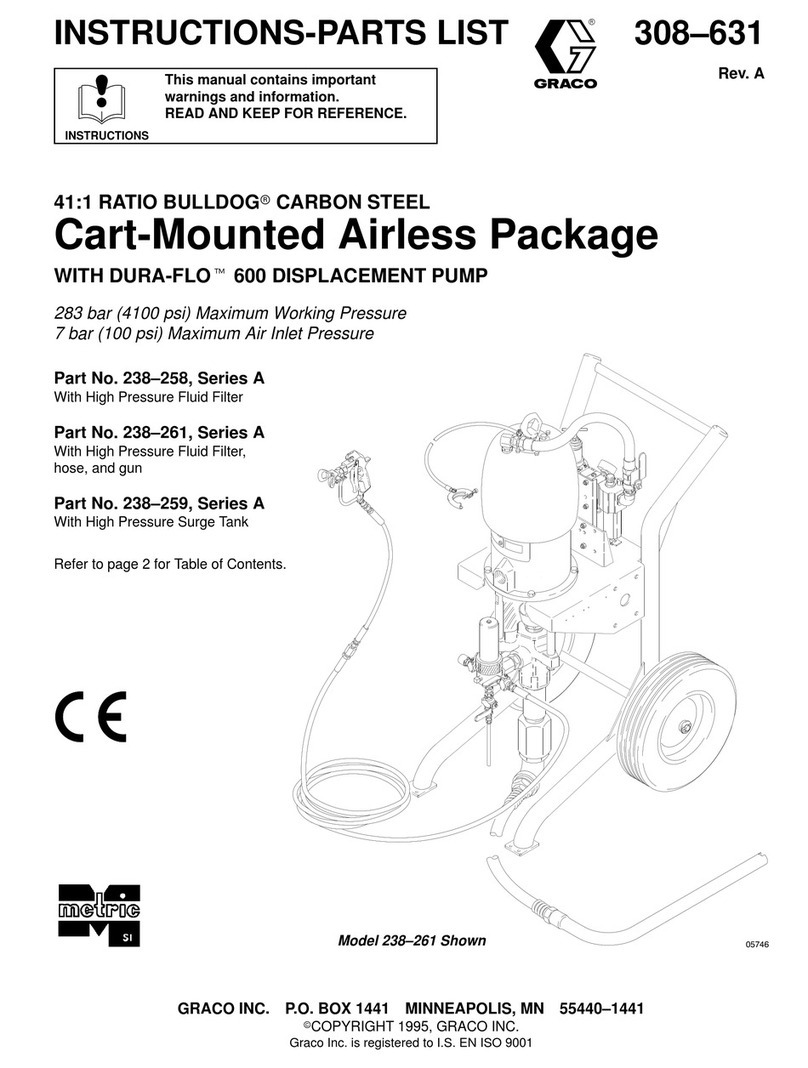

Fig. 1. Relieve system pressure. For installing any

one of the packages listed in this manual, select a site

with at least 5 ft (1.5 m) overhead clearance for the

wall mounted systems and at least 7 ft (2.1 m) for the

floor mounted systems.

Ensure that the wall is strong enough to support the

weight of the circulation package and accessories,

fluid, hoses, and stress caused during pump operation.

Ensure that you have an adequate compressed air

supply.

Bring an air supply line from the facility air supply (Z) to

the circulation package location. Be sure all air lines

are properly sized and pressure-rated for the system.

Use only electrically conductive hoses. The air hose

should have a 3/8 npt(m) thread.

Install a bleed-type shutoff valve (W) in the air line to

isolate the air line components for servicing. Install a

moisture trap and drain valve (Y) to help remove

moisture and contaminants from the compressed air

supply.

Keep the site clear of any obstacles or debris that

could interfere with the operator’s movement.

Have a grounded, metal pail available for use when

flushing the system.

Supplied Components

Refer to Fig. 1.

WARNING

A red-handled bleed-type master air valve (K) and

a fluid drain valve (F) are supplied. These compo-

nents help reduce the risk of serious injury, includ-

ing splashing of fluid in the eyes or on the skin, and

injury from moving parts if you are adjusting or

repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the air is

shut off. Trapped air can cause the pump to cycle

unexpectedly.

The fluid drain valve assists in relieving fluid pres-

sure in the displacement pump, fluid filter, hose,

and gun. Triggering the gun to relieve pressure

may not be sufficient.

DThe red-handled bleed-type master air valve (K)

is required in your system to relieve air trapped

between it and the air motor when the valve is

closed (see the preceding WARNING).

DThe fluid drain valve (F), is mounted on the

bottom of the fluid filter bowl. The fluid drain valve

is required in your system to relieve fluid pressure

in the displacement pump, fluid filter, hose, and

gun. (see the preceding WARNING).

DThe pump air filter (H) includes an air filter with a

40 micron polypropylene element, to remove harm-

ful dirt and moisture from the compressed air

supply.

DThe pump air regulator and gauge (L) controls

pump speed and outlet pressure by adjusting the

air pressure to the pump. The gauge provides a

readout of air pressure to the pump. See manual

308168 for further details.

DThe pump runaway control valve (M) protects

the pump against damage by a runaway air motor.

See manual 308201 for further details.

DThe air line lubricator (S) provides automatic

lubrication of the air motor.

DThe pump (N), run by air motor, circulates fluid

throughout the system. See pump manual 309136

and air motor manual 307741 for further details.

DFluid is supplied to the pump through the fluid

outlet (A). Fluid pressure is monitored by the two

fluid gauges (B).

DThe fluid filter (D) includes a 60 mesh (250 mi-

cron) stainless steel element to filter particles from

the fluid as it leaves the pump.

DThe fluid surge tank (J) protects against surges in

the fluid lines during gun use and system operation.

DThe fluid regulator and gauge (V) controls fluid

outlet pressure. The gauge provides a readout of

fluid pressure at the outlet. See manual 307107 for

further details.

DFluid is returned from the circulation package to the

the system through the fluid return valve (U). See

valve manual 307628 for further details.