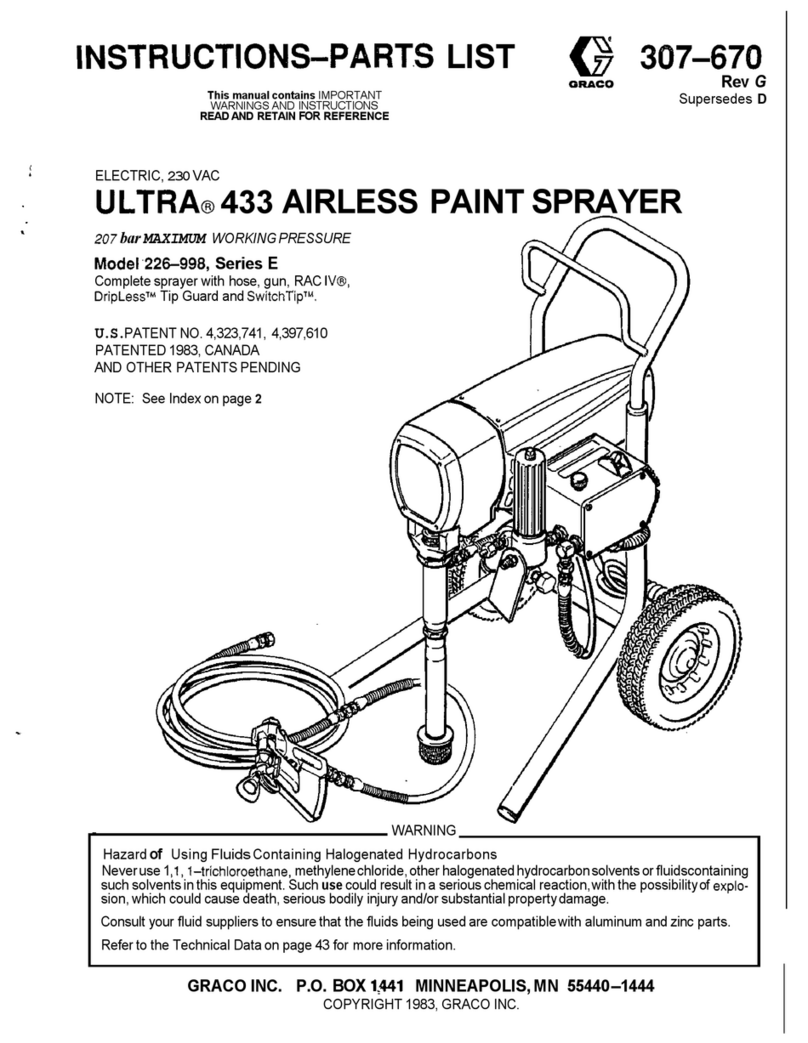

7306-863

Operation

Adjust

the Spray Pattern

WARNING

INJECTION HAZARD

T

o reduce the risk of serious injury

,

whenever you are instructed to relieve

pressure, follow the

Pressure Relief

Procedure

on page 6.

1.

Relieve pressure.

2. T

o adjust the spray pattern direction, engage the

safety latch. Loosen the tip guard retaining nut.

T

urn the spray tip so the groove is horizontal for a

horizontal spray pattern and vertical for a vertical

pattern. T

ighten the nut.

3.

The spray tip orifice size and spray angle deter

-

mines the coverage and size of pattern. When

more coverage is needed, use a larger spray tip

rather than increasing fluid pressure.

WARNING

To reduce the risk of a fluid injection injury, NEVER

use the gun with the tip guard or trigger guard

removed

CAUTION

Openings

in the tip guard are designed to reduce

paint buildup on the guard while spraying. Any

damage to the sharp edges of the openings causes

paint to collect at that area. T

o reduce the risk of

damage, never hang the gun by the tip guard.

Cleaning and Clearing the Spray T

ip

WARNING

To

reduce the risk of

serious injury from fluid injection

or

splashing, always follow the

Pressure Relief Pro

-

cedure on page 6 before cleaning and clearing the

spray

tip.

Clean off the front of the tip frequently during the day’s

operation

and at the end of the work day

. Then use a sol

-

vent

soaked brush to clean the spray tip and to keep fluid

buildup

from drying in and clogging the spray tip.

If the spray tip clogs while spraying, release the spray

gun trigger, engage the safety latch, shut off the pump,

and follow the Pressure Relief Procedure on page 2.

Then remove the spray tip and blow out the obstruction

with

air from the front

of the spray tip, or let the spray tip

and

gun nozzle soak long enough to dissolve the obstruc

-

tion.

If the obstruction won’t dissolve, jar it out by

tapping

the

back of the spray tip against a flat surface.

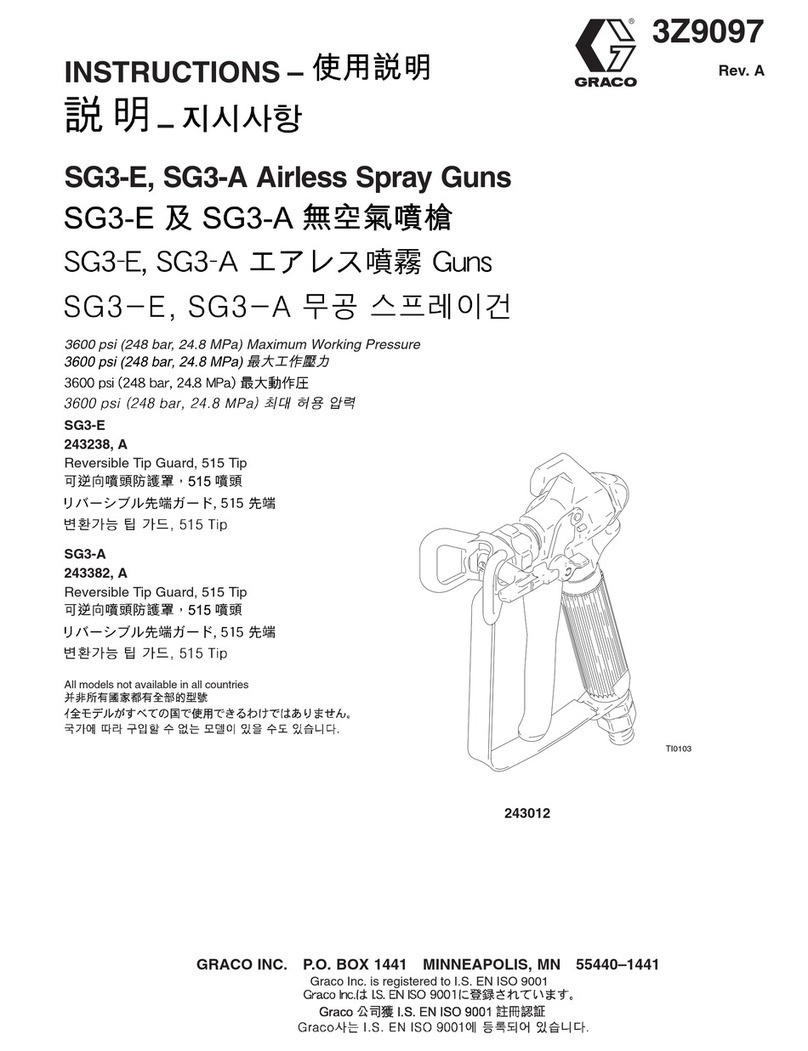

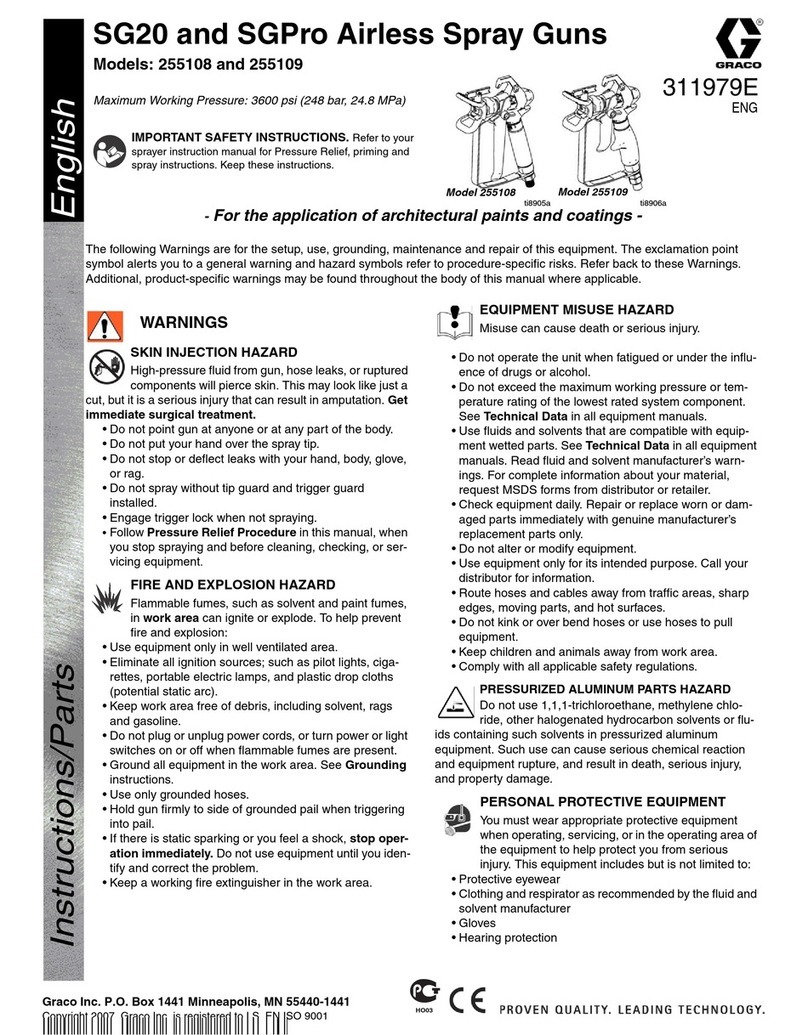

When changing spray tips, take a moment to check the

tightness of the valve seat (21). It should be torqued to

190–210

in–lb (23–24 N.m). See Fig 3.

CAUTION

NEVER soak the entire gun in solvent. Prolonged

exposure to solvent can ruin the packings.

Flushing the Gun

WARNING

Before

flushing

, be sure

the entire system and flush

-

ing

pails are properly grounded. Refer to

Grounding

on page 5. Follow the Pressure Relief Procedure

on page 6, and

remove the spray tip from the gun.

Always use the lowest possible fluid pressure, and

maintain firm metal-to-metal contact between the

gun

and the pail

during flushing to reduce the risk of

a

fluid injection injury

, static sparking and splashing.

See Fig 3.

Relieve pressure. Remove the spray tip. Flush the gun

and spray system with a compatible solvent. Always

flush

the gun before the fluid being sprayed can dry in it.

Fig

3

0959

MAKE

FIRM MET

AL–TO–METAL

CONT

ACT BETWEEN GUN AND

GROUNDED P

AIL DURING

FLUSHING

TORQUE TO

190–210 in–lb

(23–24 N.m)

21