WA

WpIlNG

HIGH

PRESSURE SPRAY CAN CAUSE SERIOUS INJURY.

FOR

PROFESSIONAL USE

ONLY.

Read and understand all instruction manuals before operating equipment.

OBSERVE

ALL WARNINGS.

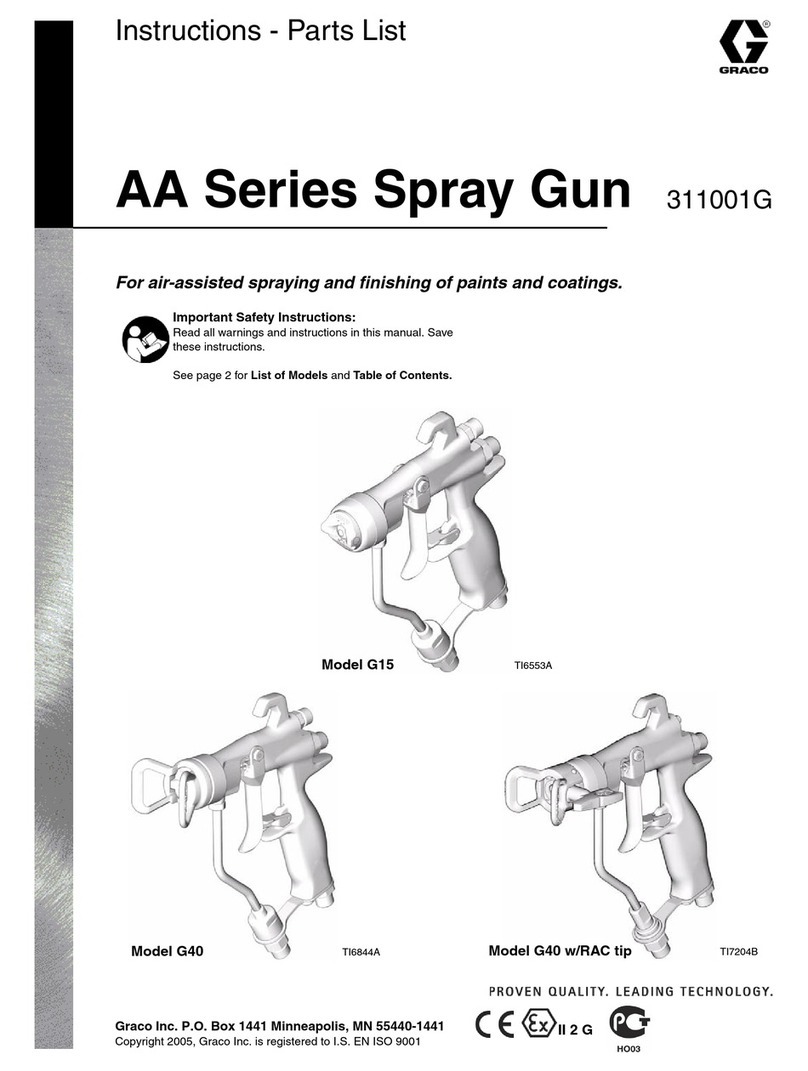

INJECTION

HAZARD SPRAY

GUN

SAFETY

Fluids under high pressure from spray or leaks can penetrate the skin

and cause extremely serious injuty, including the need for amputa- When spray gun is not actually spraying, always set the gun safety

tion. latch in the closed or "SAFE" position, making the trigger in-

operative.

NEVER

point the spray gun at anyone or any pan of the

hod"

DO

NOT REMOVE

OR

MODlM

any pan of the gun.

NEVER

put hand

or

fingers over the spray tip.

NEVER

try to stop

or

deflect leaks with your hand

or

body.

Check

the

gun fluid diffuser operation by using the

lowest

possible

spray pressure with spray tip removed. Trigger gun and maintain firm

metal to metal contact between aun and metal waste container. Fluid

emitted should be diffused into

in

irregular stream

ALWAYS

have the tip guard in place when spraying. CHECK OPERATION OF ALL GUN SAFETY DEVICES BEFORE

MEDICAL TREATMENT Always remove the

tip

from the gun

to

clean

It.

EACH USE.

If any fluid a ears to enetrate our 'skin

ENPZRGENCQMEOICA~ CARE i\$edNCE.

DO

NOT TREP

Be

very careful when removing the spray

tip

or hose from gun. A

LT AS A SIMPLE CUT. open the drain valve. then loosen

tip

guard or hose coupling slightty

plugged line contains fluid under pressure. If tip or line is plugged.

Tell the doctor exactly what

fluid

was injected. For treatment instruc- and relieve the pressure slowly before removing completely.

.:"_

L

2

"."

"I,

.L_

LIUII~

Im"C1

""U'

UUrlYl

w11

111.1

NATIONAL POISON CENTER NETWORK

14121681-6669

AVOID

COMPONENT

RUPTURE

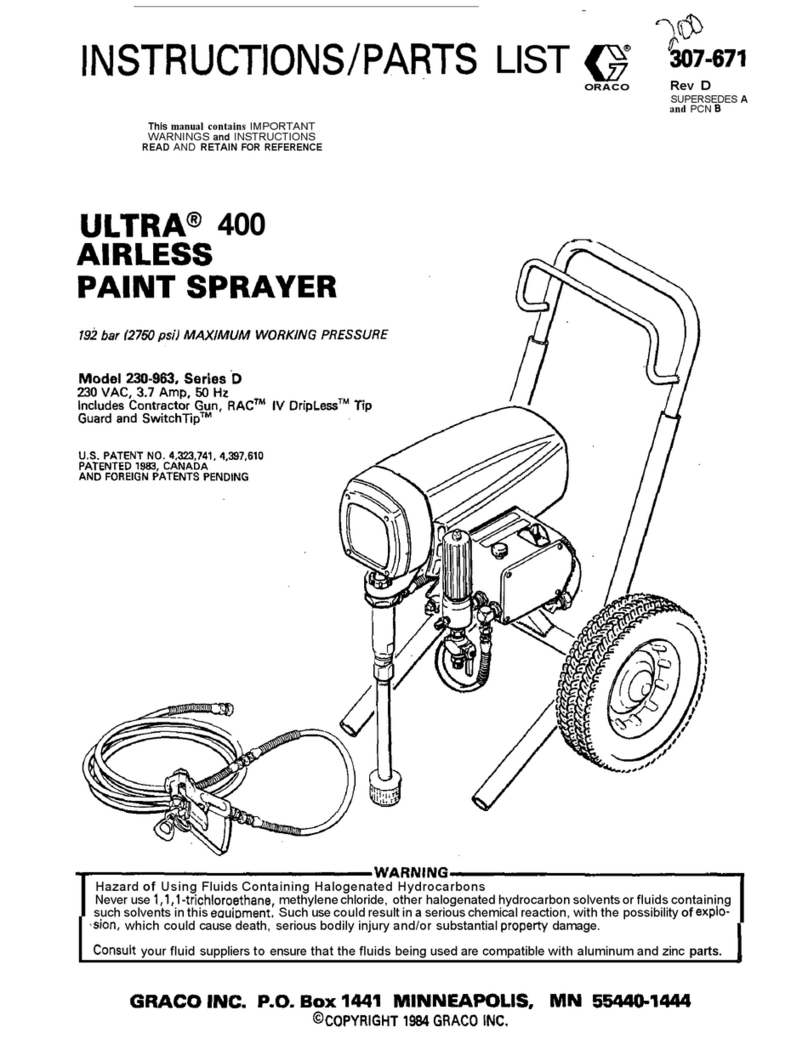

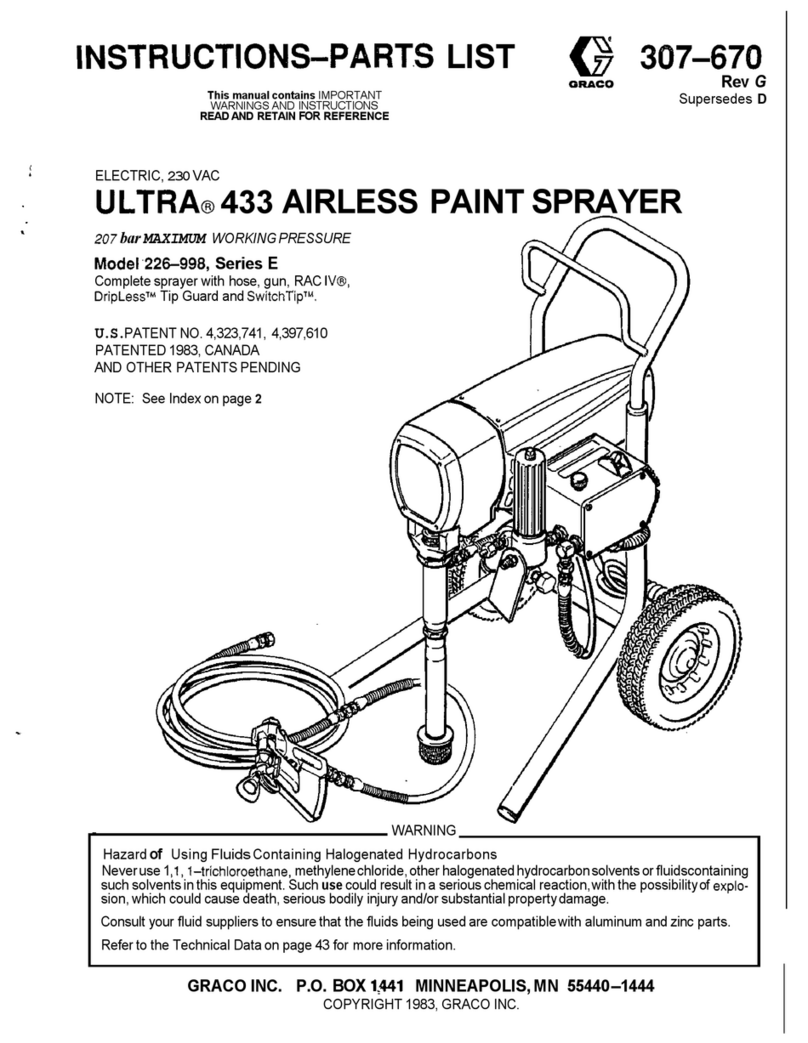

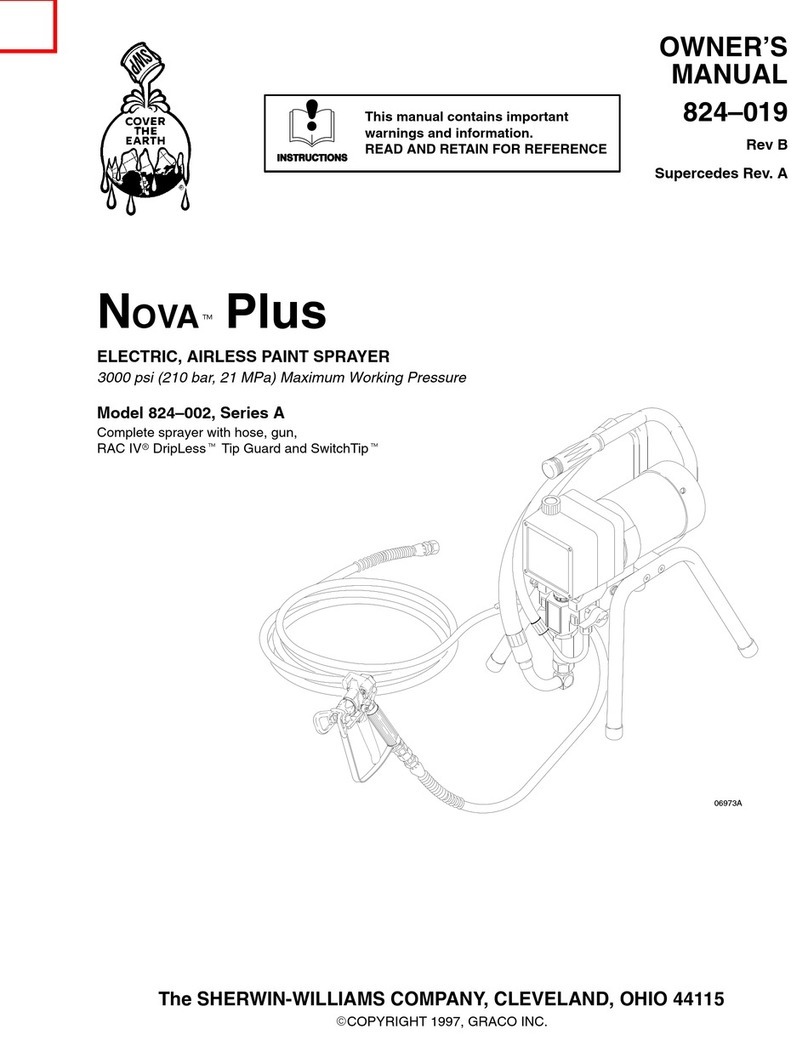

This unit develops

3ooo

psi

(210

bar) fluid pressure

at

75

cycles per

minute. Always be Sure that

all

components have a maximum working

DO

not use hose to pull unit. Before each use. check entire hose for

pressure rating

at

least as high.

cuts, leaks, abrasion

or

bulging of cover or damage of movement of

couplings.

If

any of these conditions exist. repiace the hose im-

mediately. Never

use

tape

or

any device

to

attempt

to

mend the hose.

NEVER

leave a pressurized unit unattended.

DO

NOT ABUSE HOSE: Improper

use

or

handling of hose could

Do

not us chemicals

or

agents

in

the hose which are not compatible

with nylon tube and urethane cover of the hose.

resuh

in

hose failure and possible personal injury or properly damage.

Handle and route hose carefully to avoid kinking, abrasion, cutting or NEVER Al7EMPT

TO

RECOUPLE THE

HOSE1

exposure to temperatures above

1WF

182°CI

or below -4OOF

I4"CI.

Tighten

a11

fluid connections SEcurely before each use.

PREVENT

STATIC

SPARKING

Always be sure all equipment and objects being sprayed are properly

grounded. The high velocity flow of fluid creates Static electricity.

Use

only conductive

or

grounded fluid hoses for airless applications.

BE

sure

that gun is grounded through hose connections.

Once each week. check ele6trical mistance of hose lwhen using

end) mistance of unpressurized hose must not exceed

29

megohms

multiple hose aslemblies. check overall resistance). Overall lend to

(max.1 for any coupled length or combination of hose lengths.

If

hose

exceeds these limits, replace

it

immediately.

Never exceed

500

ft

(150

ml overall combined hose length..

This unit has a 3-prong grounding plug to protect you from electric

shock. Be sure to plug the unit into a properly grounded outlet that

will accept the $prong plug,

Do

not remove the thirdprong.

KEEP CLEAR

OF

MOVING PARTS

The electric motor has

an

overheating prOtECtbn device which

automatical& restans the motor when

it

cools.

So,

before examining

or working on a motor which has stopped, shut

off

the unit, relieve

pressure and pull out the electrical plug. This will avoid the hazard

of

the motor starting Unexpectediy.

The green wire of the power supply cord

is

connected to the unit

chassis and motor frame for grounding continuity. The other

two

wires are connected to the motor windings through the switch.

spraying. If you us an extension cord,

it

must have 3 wires of

at

least

Plug into

an

outlet

at

least

20

ft

(6ml from the area where you are

12

gauge

12.5

mdl a?d should not

be

over

la,

ft

130.3

ml long.

When flushing equipment. remove spray tip. use th-

lowest

possible

pressure, and maintain firm metal to metal contact between gun and

metal waste container. This reduces the chance of static sparking.

warnings.

Follow the coating and solvent manufacturer's safety precautions and

USE EXTREME CARE WHEN SERVICING

power source and carefully relieve fluid prmure

by

triggering spray

Before removing any pan far cleaning

or

sewicing, always disconnect

gun, engaging trigger safety and any other equipment safety locks.

and opening any drain

or

bleeder vaives. Leave drain valve open dur-

ing servicing. Remove tip from gun for cleaning.

KEEP CLEAR

of

moving pans when unit is running; do not put your

fingers into any openings

in

shield.

ALWAYS CHECK to be sure switch is OFF and

all

lines are clear of

moving

paM

before plugging in the power cord.

ALWAYS unplug unit before removing gearbox cover for any reason.

IMPORTANT

United States Government safety standards have been adopted under the Occupational Safety and Health Act. These standards

-

Particularly the

egwpment.

General Standards, Pan

1910,

and the Construction Standards, Pan

1926

-

should be consulted in connection with your use of airless spray

I

"-

"-