EQUIPMENT MISUSE HAZARD

Any misuse of the spray equipment or accessories, such as

General Safety

overpressurizing, modifying parts, using incompatible

chemicalsandfluids, or using worn or damagedparts,can

causethem to ruptureand result

in

fluid injection, splashing

in

the eyesor onthe skin, or other seriousbodily injury, fire, ex-

plosion

or

property damage.

could cause

it

to malfunction.

NEVER alter or modify any

part

of this equipment; doing

80

CHECK allsprayequipmentregularlyandrepair or replace

worn or damaged parts immediately.

Alwayswearprotectiveeyewear,glovesand clothing as

recommendedby the

fluid

and solvent manufacturer.

System

Pressure

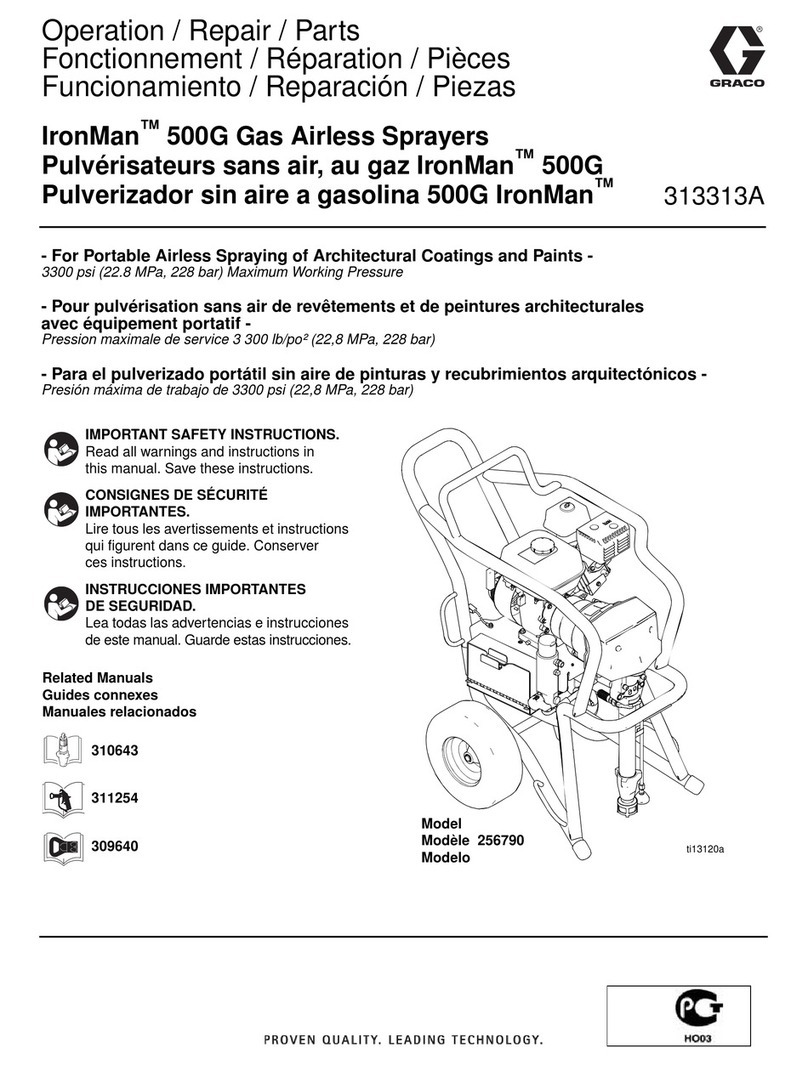

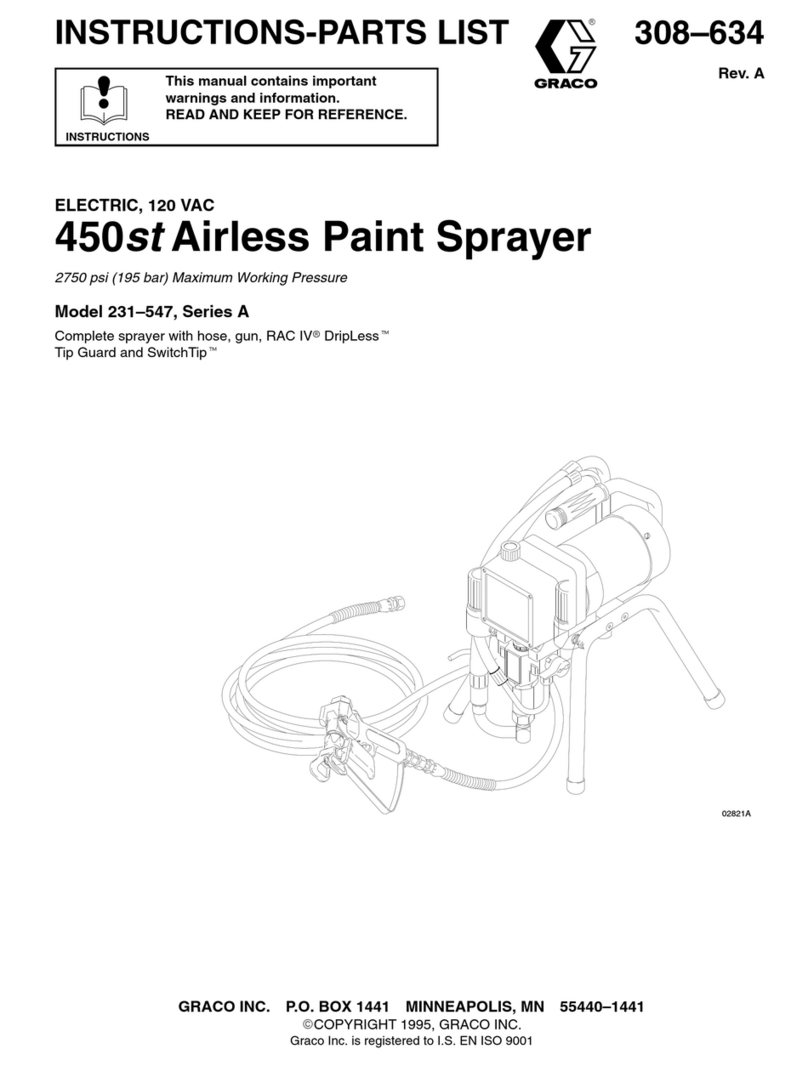

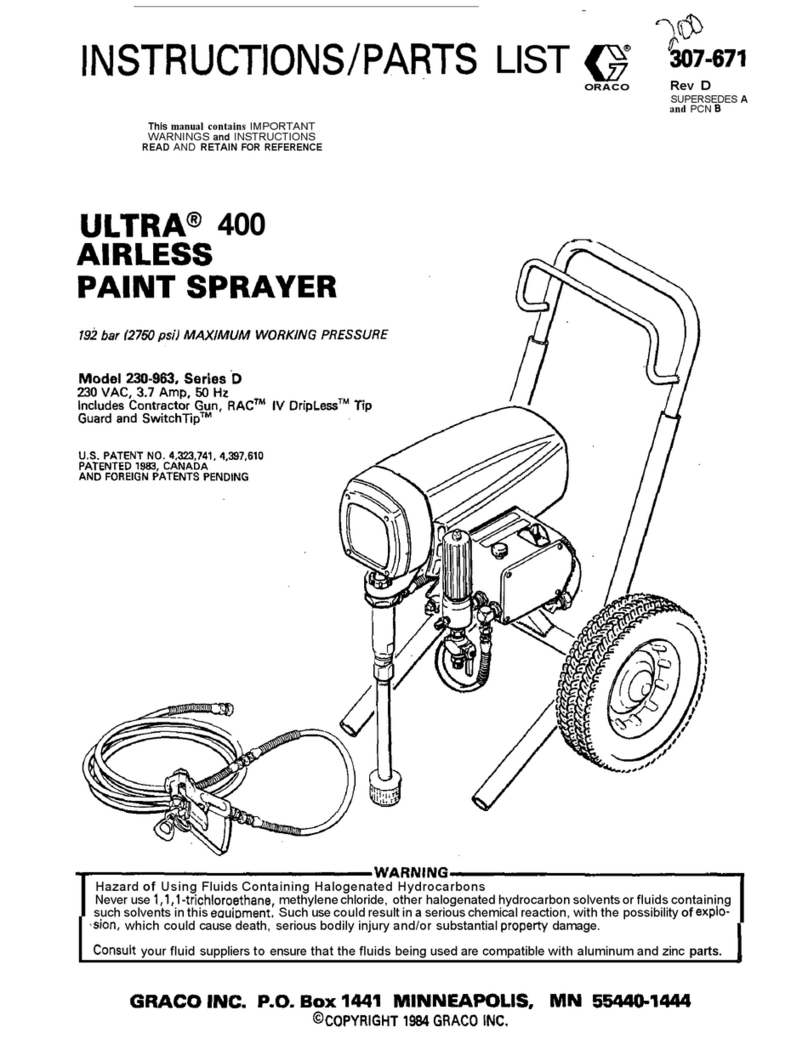

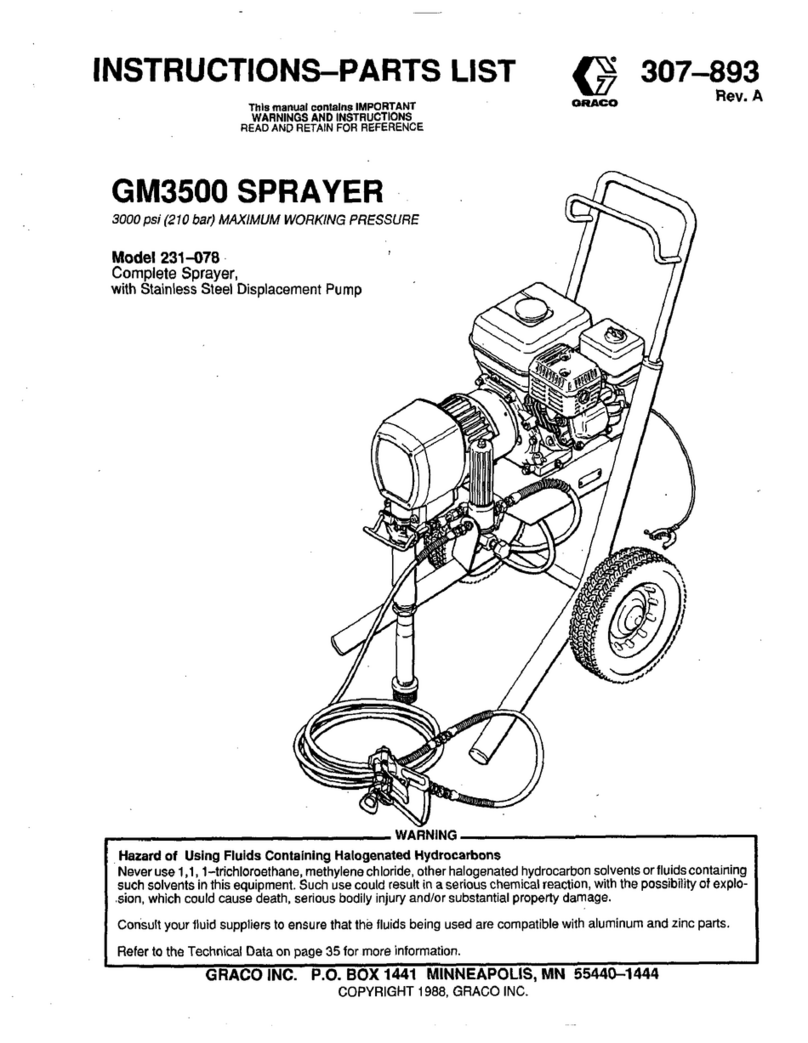

Thissprayercandevelop

2750

psi

I195

berl

MAXIMUM

accessoriesare rated to withstand the maximum working

WORKING

PR€.SSUR€.

Be sure

that

all spray equipment and

pressureof this sprayer.

DO

NOT exceedthe maximumwork-

ing pressure of anycomponent oraccessory used'in the

witem.

Fluid and Solvent Compatlbillty

Alwaysread the

fluid

andSolventmanufacturer'sliterature

before usingthem

in

this sprayer.

HOSE

SAFETY

Highpressurefluid

in

thehoses canbevery dangerous.If the

damage or misuse,the high pressure spray emittedfrom

it

can

hose develops aleak, split or rupturedueto any kindof wear,

cause

a

fluid injection injury or other serious bodily injury or

propany damage.

ALL FLUID HOSES MUST HAVESPRING GUARDS ON

kinks or bendsat or closeto thecoupling which can result

in

BOTH

ENDS1

The spring guards help protect the hose from

hose rupture.

TIGHTEN allfluid connections securely before each use. High

pressure fluid can dislodgealoosecouplingor allow high

pressure sprayto be emitted from thecoupling.

NWER use a damaged hose. Before each use. checkthe en-

tirehosefor cuts, leaks, abrasion,bulging cover,ordamage or

movement of the hose couplings. If any of these conditions

exist, replace the hose immediately.

DO

NOTtry torecouple

highpressure hoseor mend

it

withtape or any other device. A

repairedhosecannot containthe high pressure fluid.

HANDLEAND ROUTE

HOSES

CAREFULLY.

Do

not pull on

hosesto move equipment.

Do

notusefluidsormlventswhich

are not compatiblewith the innertube and cover ofthe hose.

DO

NOTexposeGracohose to temperaturesabove180°F

(82°C) or below

-4O'F

I-4O"C).

Proper hosegroundlng contmulty

IS

essentialtomaintaining e

Hose

Groundlng Contlnulty

grounded spray system. Checktheelectrical resistanceofyour

fluid hosesat least once a week.Ifyour hose doesnothave a

tag on

it

which specifies the maximum electrical resistance,

contact the hose supplier or manufacturer for the maximum

resistancelimits.Usearesistancemeter

in

the appropriate

range for your hoseto check the resistance. If the resistance

exceeds the recommended limits, replace

it

immediately. An

ungrounded or poorly grounded hose canmake your system

hazardous.AlsoreadFIRE

OR

EXPLOSION HAZARD.

FIRE

OR

EXPLOSION HAZARD

through the pump and hose. If every part of the spray equip-

Static electricity is created by thehighvelocity flow of fluid

ment is not properly grounded, sparking may occur, and the

systemmaybecomehazardous.Sparkingmayalsooccur

when pluggingin or unplugging a power supply cord. Sparks

can ignite fumes from solvents and the fluid being sprayed,

dust

particles and other flammable substances, whether you

are spraying indoorsor outdoors, and can cause

a

fire or ex-

plosionandseriousbodilyinjury

and

property damage.

away from the sprayer

and

the spray area.

Do

not plug

in

or

Always plug the sprayer into

an

outlet at least

20

feet

16

ml

any chance of igniting fumes still

in

the air.

unplug any power supply cordsinthespray areawhenthereis

while using this equipment.STOP SPRAYINQ

hEDL

If

you experienceanystaticsparkingorevenasli

ht

shock

ATELY. Checktheentire systemfor proper grounding.

Do

not

corrected.

usethe system againuntilthe problemhas beenidentified and

Groundlng

To reducethe risk of static sparking, ground the sprayer and

all other spray equipment used or located in the spray area.

CHECK yourlocalelectricalcode for detailedgrounding

in-

structions for your area and type of equipment. BE SUREto

ground allof this spray equipment:

1.

2.

3.

4.

5.

6.

7,

Spreyer: plug the power supply cord, or extension cord,

eachequippedwithan undamaged three-prong plug,into

a properly grounded outlet.Donotuse anadapter.

All

ex-

tension cords musthave three wires andbe rated for

15

amps.

Fluid

hoses: use

only

groundedhoses

with

a maximumof

500'feet

(150

m)combinedhoselengthtoensure ground-

ing continuity. Refer to Hose Groundlng Conrlnulty.

Spray

gun:

obtaingroundingthroughconnection to a

properly groundedfluid hose and sprayer.

Objectbeing sprayed: accordingto local code.

Fluid

supply container: accordingto local code.

All

solventpails used when flushing, according to local

code. Useonlymetalpeils, which are conductive.

Do

not

or cardboard, which interruptsthe grounding continuity.

placethe

pail

ona non-conductivesurface, suchas paper

To

maintaingroundingcontinuitywhenflushingorreliev-

ing

pressure, alwaysholda metalpartof thegunfirmly to

the side of agroundedmetalpail, then trigger the.gun.

Flushing Safety

Reducethe riskofinjection injury, staticsparking, orsplashing

of

this manual.Follow the Pressure Rellef Procedure

on

byfollowing the specific flushing procedure givenon page

12

page

4,

and removethespray

tip

befOr.9flushing. Holda metal

part

of the gun firmly tothe side of a metal pail anduse the

lowest possiblefluid pressure during flushing.

MOVING PARTS HAZARD

Moving parts can pinch or amputateyourfingers or other

bodyparts. KEEPCLEAR of movingparts when starting or

operating the sprayer. Unplug the sprayer, and follow the

Pressure Rellef Procedure on aaae

2.

beforecheckina or

servicing anipart of the sprayeitoprevent

it

from stariing

accidentally.

IMPORTANT

ticularly the General Standards, Part

1910,

and the Construction Standards, Part 1926-should be consulted.

UnitedStates Government safety standards have been adopted undertheOccupational Safety and HealthAct. These standards-par-

307-758

3