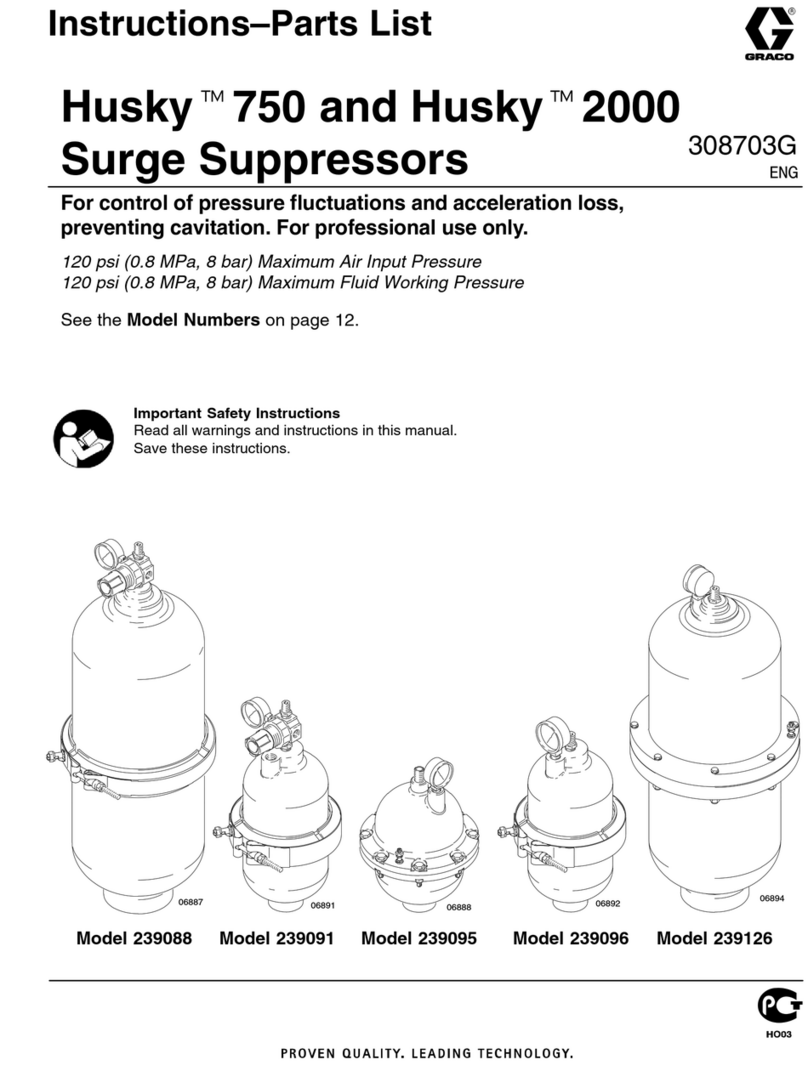

Installation

Installation Installation

Installation

General General

GeneralInformation Information

Information

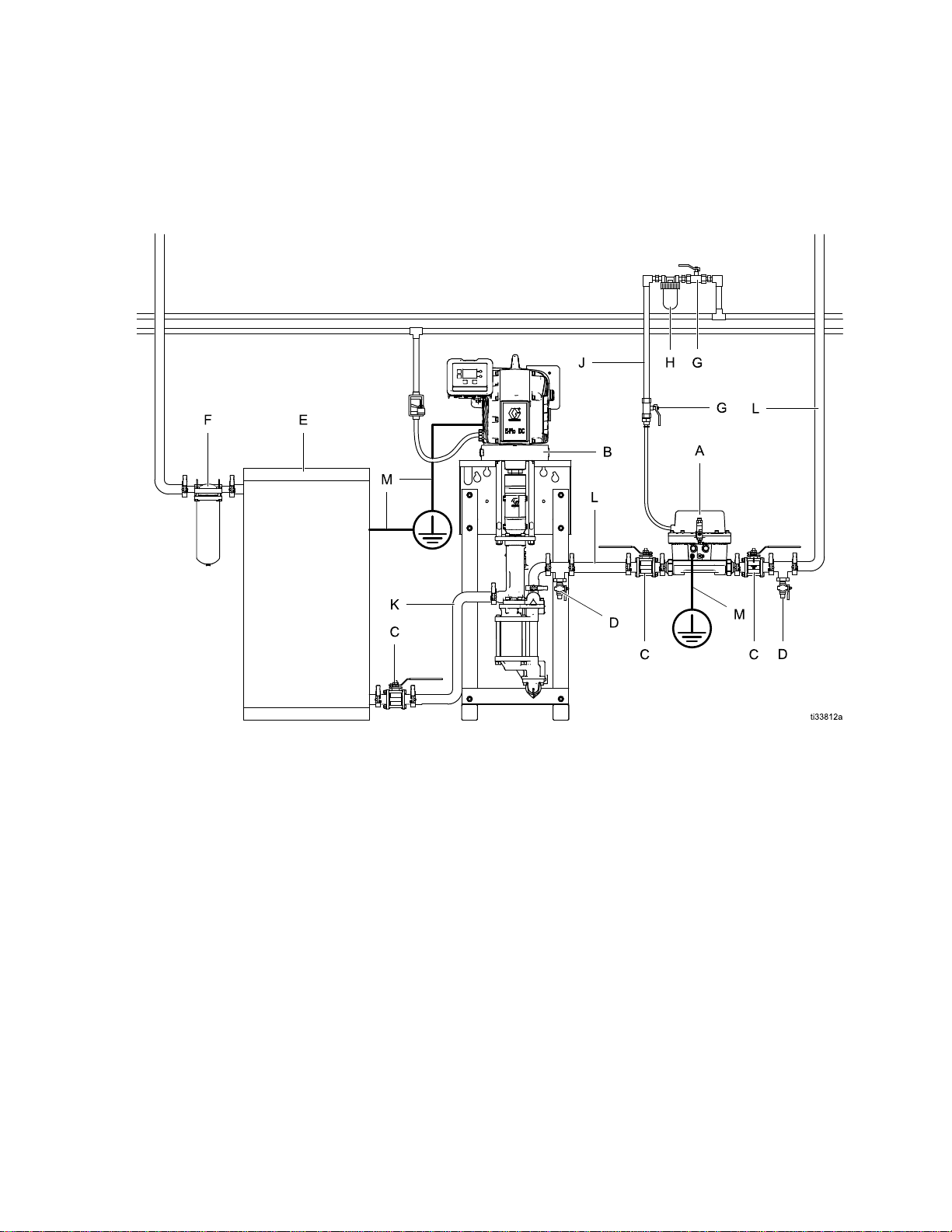

•TheTypicalInstallationisonlyaguideforinstalling

systemcomponentsandaccessories.Itisnot

anactualsystemdesign.ContactyourGraco

distributorforassistanceindesigningasystemto

suityourparticularneeds.

•AlwaysuseGenuineGracoPartsandAccessories,

availablefromyourGracodistributor.Ifyousupply

yourownaccessories,besuretheyareadequately

sizedandpressure-ratedforyoursystem.

•Referencenumbersandlettersinparentheses

refertothereferencenumbersintheguresandin

thepartslists.

Grounding Grounding

Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

Groundthesuppressorandtherestofyoursystem.

Groundthesuppressorandallothersprayequipment

usedorlocatedinthesprayarea.Thefollowingare

minimumrequirementsforgroundingabasicspray

system.Yoursystemmayincludeotherequipmentor

objectswhichmustalsobegrounded.Alwayscheck

yourlocalelectricalcodefordetailedgrounding

instructions.Besureyoursystemisconnectedtoa

trueearthground.

•Pump: Pump:

Pump:Useagroundwireandclampasdescribed

inyourseparatepumpinstructionmanual.

•Air Air

Aircompressors compressors

compressorsand and

andhydraulic hydraulic

hydraulicpower power

powersupplies: supplies:

supplies:

Followthemanufacturer’srecommendations.

•Air Air

Airand and

anduid uid

uidlines: lines:

lines:Useonlygroundedhoses

withamaximumof150m(500ft)combined

hoselengthtoensuregroundingcontinuity.See

HoseGroundingContinuity,page6.

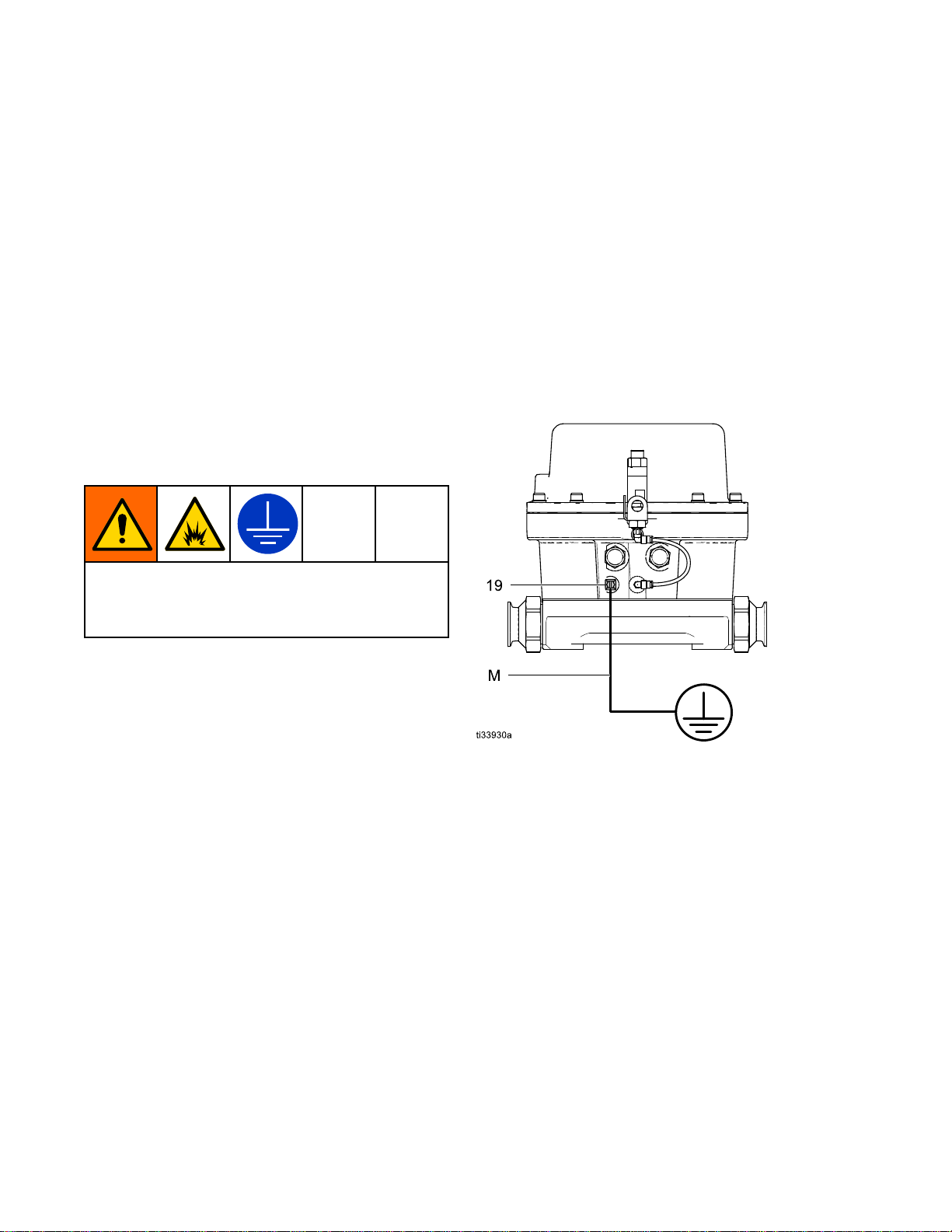

•Surge Surge

Surgesuppressor: suppressor:

suppressor:Useagroundwireandclamp.

Loosenthegroundingscrew(19).Insertoneend

ofa12ga(1.5mm2)minimumgroundwire(M)

behindthegroundingscrewandtightenthescrew

securely.Connecttheclampendoftheground

wiretoatrueearthground.Foragroundwireand

clamp,orderPartNo.222011.

•Spray Spray

Spraygun: gun:

gun:Obtaingroundingthroughaconnection

toaproperlygroundeduidhoseandpump.

•Object Object

Objectbeing being

beingsprayed: sprayed:

sprayed:Followyourlocalcode.

•Fluid Fluid

Fluidsupply supply

supplycontainer: container:

container:Followyourlocalcode.

•All All

Alluid uid

uidpails pails

pailsused used

usedwhen when

whenushing: ushing:

ushing:Followyour

localcode.Useonlyconductivemetalpails

placedonagroundedsurface.Donotplacethe

pailonanonconductivesurface,suchaspaper

orcardboard,whichinterruptsthegrounding

continuity.

•Tomaintaingroundingcontinuitywhenushingor

relievingpressure,alwaysholdametalpartofthe

gunrmlytothesideofagroundedmetalpail,

thentriggerthegun.

Figure1GroundtheSuppressor

Hose Hose

HoseGrounding Grounding

GroundingContinuity Continuity

Continuity

Properhosegroundingcontinuityisessentialto

maintainingagroundedspraysystem.Checkthe

electricalresistanceofyourairanduidhosesat

leastonceaweek.Ifyourhosedoesnothavea

tagonitwhichspeciesthemaximumelectrical

resistance,contactthehosesupplierormanufacturer

forthemaximumresistancelimits.Usearesistance

meterintheappropriaterangeforyourhoseto

checktheresistance.Iftheresistanceexceedsthe

recommendedlimits,replacethehoseimmediately.

Flushing Flushing

FlushingSafety Safety

Safety

Beforeushing,besuretheentiresystem

andushingpailsareproperlygrounded.See

Grounding,page6.

63A6103A