HIGH

PRESSURE

SPRAY

CAN CAUSE SERIOUS INJURY.

FOR PROFESSIONAL USE ONLY. OBSERVE ALL WARNINGS.

.

Read

and

understand

all

instruction

manuals

before

operating

equipment.

FLUID

IMJECTIBAI

HAZARD

General

Safety

This equipment generatesveryhighfluid pressure. Sprayfrom

the gun,leaks or rupturedcomponents can inject fluid

through yourskinand into yourbodyandcauseextremely

serious bodily injury, includingthe needfor amputation. Also,

fluid injected orsplashed intothe eyes cancauseserious

damage.

NEVER pointthespray gun or dispensing valveat anyone orat

anypart of the body. NEVER put hand or fingersover the

spray tip

or

nozzle. NEVER try to"blow backmaterial: this is

NOT an

air

spray system.

when spraying.

If using

a

spray

gun,

ALWAYS have the tip guard

in

place

ALWAYS follow the Pressure Relief Procedure, below,

before

cleaningor removingthespray tip or nozzleorservicing

any system equipment.

Spray

Gun

or

Dispensing

Valve

Safety

Devices

each use.

Do

not removeor modify any part

of

the gun; this

Besure all gun safetydevices areoperatingproperly before

cancause

a

malfunction and result in serious bodily injury.

Safety Latch

Whenever you stop spraying, even for

a

moment, always set

the gun safety latch

in

the closedor "safe" position, making

thegun inoperative. Failuretoset thesafetylatchcan result in

accidental triggering of the gun.

Diffuser (Spray

guns

only)

The gun diffuser breaksupspray and reducesthe risk of injec-

tion when the tip is not installed. Check diffuseroperation

regularly.Follow the PressureRelief Procedure, below.

thenremovethe spray tip. Aimthe gun into

a

metalpail,

holding the gun firmly to.the pail. Using the lowestpossible

to an irregular stream, replacethe diffuser immediately.

pressure, trigger the gun. Ifthefluid emitted

is

not

diffused in-

..

.

NEVER try tostop or deflect leaks with your hand or body. ALWAYS have the tip guard In placeon the spray gun while

Tip

Guard

(Spray

guns

only1

before each use.

Besure equipmentsafety devicesare operatingproperlyspraying.The tip guardalertsyou to the injection hazardand

helps prevent accidentally placing your fingers or any part of

vour bodv closetothe mrav

tin.

Medlcal

Treatment

If any fluid appears to penetrateyour skin,get

Spray

Tip

and

Nozzle

Safety

~"

,

~ ~~~ ~~ ~~

.~

~,

~~r

EMERGENCY MEDICAL CARE AT ONCE.

DO NOTTREAT

AS

A SIMPLE CUT.

Use extremecaution when cleaningor changing spray tips or

Tell the doctor exactlvwhat fluid was iniected.For treatment nozzles. If the spraytip or nozzle clogs while spraying, engage

thegunsafetylatchimmediately. ALWAYS follow the

instructions,haveyour doctor call the

.

NATIONAL POISON CENTER NETWORK

(412)681"9

Pressure Relief Procedureand then remove the spraytip to

clean

it.

pressure is fully relieved andthe gun safety latch isengaged.

NEVER wipe off build-up around the spray tip or nozzle until

____

~_____

~~

Pressure

Relief

Procedure

To reduce

the

risk of seriousbodilyinjury,includinginjectionorinjury from movingparts,always follow thisprocedure

whenever youshut

off

the pump, whenchecking or servicing any part ofthe spray system, when installing, cleaningor chang-

ingspray tips or nozzles, and whenever you stop spraying.

(1)

Engagethe gun safety latch.

12)

Shut off theair tothe pump.

13)

Closethe bleed-type masterair valvetopreventthepumpfromstarting accidentally.

(41

Disengagethegunsafety latch.(5).Hold

a

metal partof the gunfirmly to the sideof

a

metal pail, and trigger the guntorelieve pressure.161 Engagethe gunsafety latch.

(7)Openthe pumpoutlet drain valveor bleeder valve,

181

Leavethe drain valve or bleeder valve openuntilyouare readytospray

again.

j

steps

above, VERY SLOWLY

loosen

the

tip

guard retainingnutor hose end coupling and relieve pressure gradually, then loosen

If

you

suspect that the spray tip or hose

is

completely clogged, or that pressure has not been fully relieved after following the

comoletelv. Now

clear

the

ti0

or hose.

~~ ~

EQUPMENT MISUSE

HAZARD

~~ ~ ~~~~

General

Safety

Anymisuseof the sprayequipmentoraccessories,such as

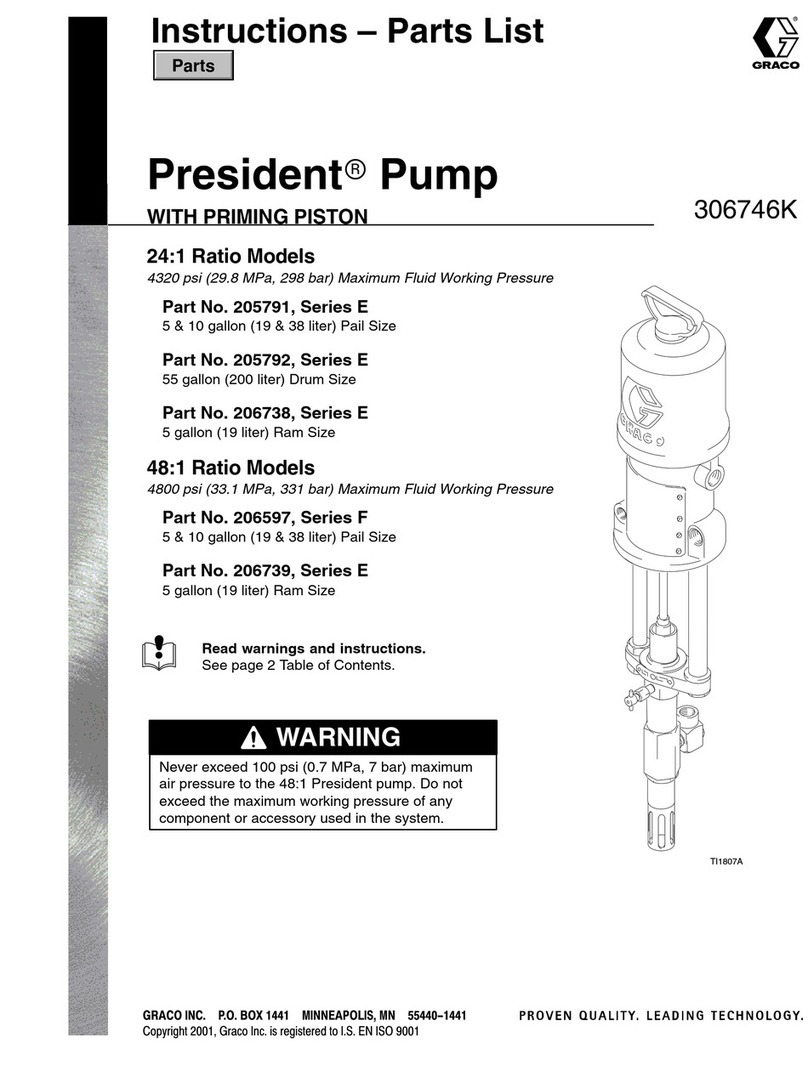

overpressurizing, modifying parts, using incompatible Model

226-250

develops

ZW

psi

I504

barl MAXIMUM

WORKINGPRESSURE

at

150

psi

110

barl incomingair

chemicalsandmaterials,orusing worn or damagedparts,canpressure.

cause them to ruptureand result in injection or other serious

bodilyinjury.fire,explosion or property damage. Model

226-251

develops

24w

psi

1165

barl MAXIMUM

NEVER alter or modify any part of this equipment; doing

so

WORKINGPRESSURE

at 120 psi

I8

bar)incoming air

pressure.

could cause

it

to

malfunction. Model

226-252

develops

4Bw

psi

1230

barl MAXIMUM

CHECK allsprayequipmentregularlyandrepairorreplace

WORKINGPRESSURE

at

120

psi

18

bar1 incomingair

worn

or

damaged pans immediately. pressure.

System

Pressure

Besure that a11 sprayequipmentandaccessoriesarerated to

Model

226-249

develops

4320

psi

13W

barl MAXIMUM

withstand the maximumworking pressureofthissprayer.

DO

pressure.nent or accessoryused

in

the system.

WORKINGPRESSURE

at

180

psi

112

bar)incomingairNOT exceed the maximum working pressure

of

anycompo-

2

306-839